Integrated trimming equipment for luggage production and processing

A luggage and trimming technology, applied in metal processing and other directions, can solve the problems of increasing the use range of equipment and affecting the trimming accuracy, and achieve the effect of increasing the use range, improving the accuracy and reducing the impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

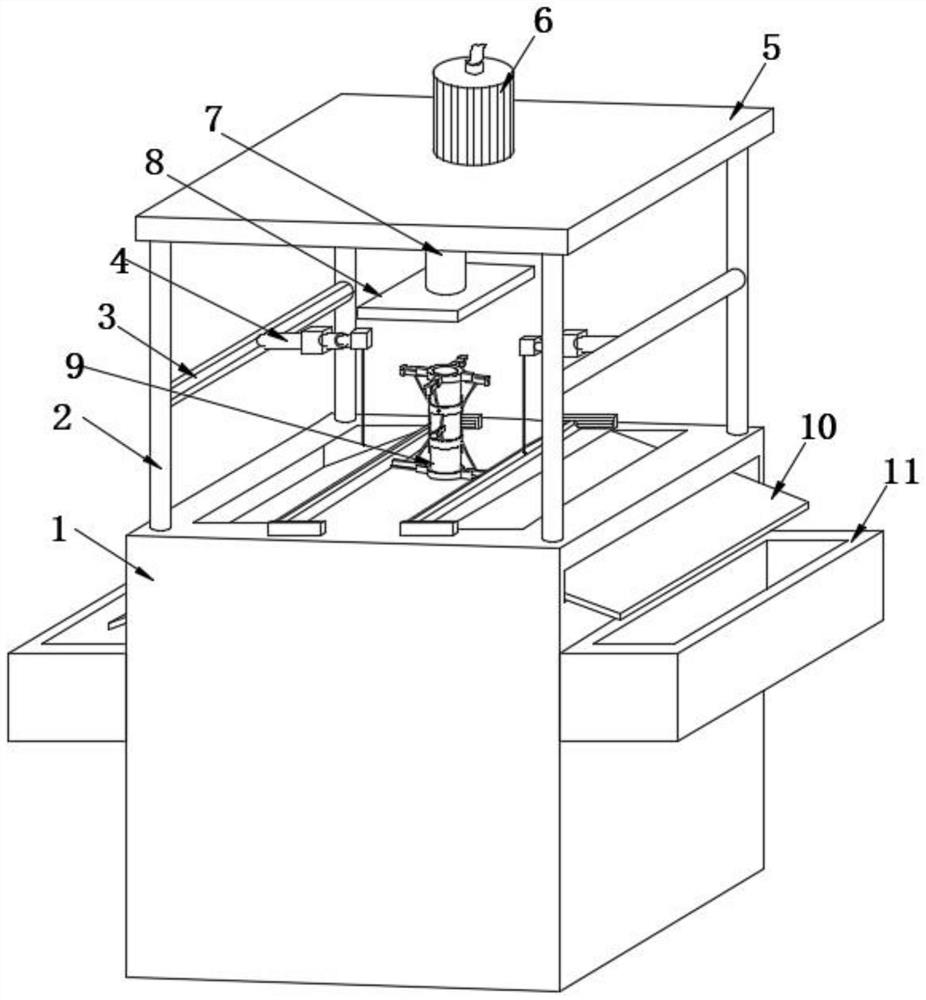

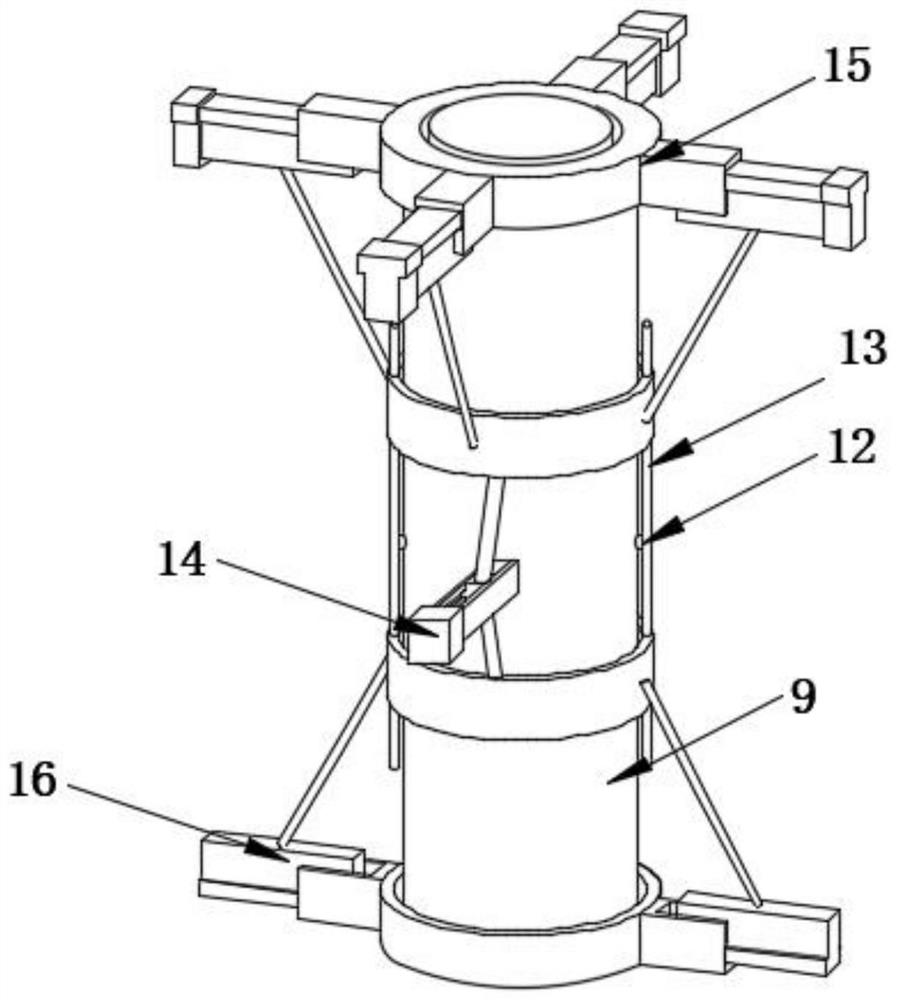

[0038] see Figure 1-9 As shown, the present invention is an integrated edge trimming equipment for luggage production and processing, including a workbench 1, a cutting chute is symmetrically opened on the upper surface of the workbench 1, and one end of the lower plate 10 is installed inside the cutting chute. , to facilitate the waste on the workbench 1 to slide from the upper surface of the lower plate 10, while the four corners of the upper surface of the workbench 1 are fixedly connected with vertical rods 2, and between the two vertical rods 2 are fixedly connected with a positioning crossbar 3 , one side of the positioning cross bar 3 is provided with a trimming knife rest 4, and when luggage is trimmed, by controlling the external power supply, the trimming knife rest 4 is started to work, so that the trimming knife rest 4 is positioned on the positioning cross bar 3 The inside of the vertical bar 2 is fixedly connected with a flat cover 5 at the end of the vertical b...

Embodiment 2

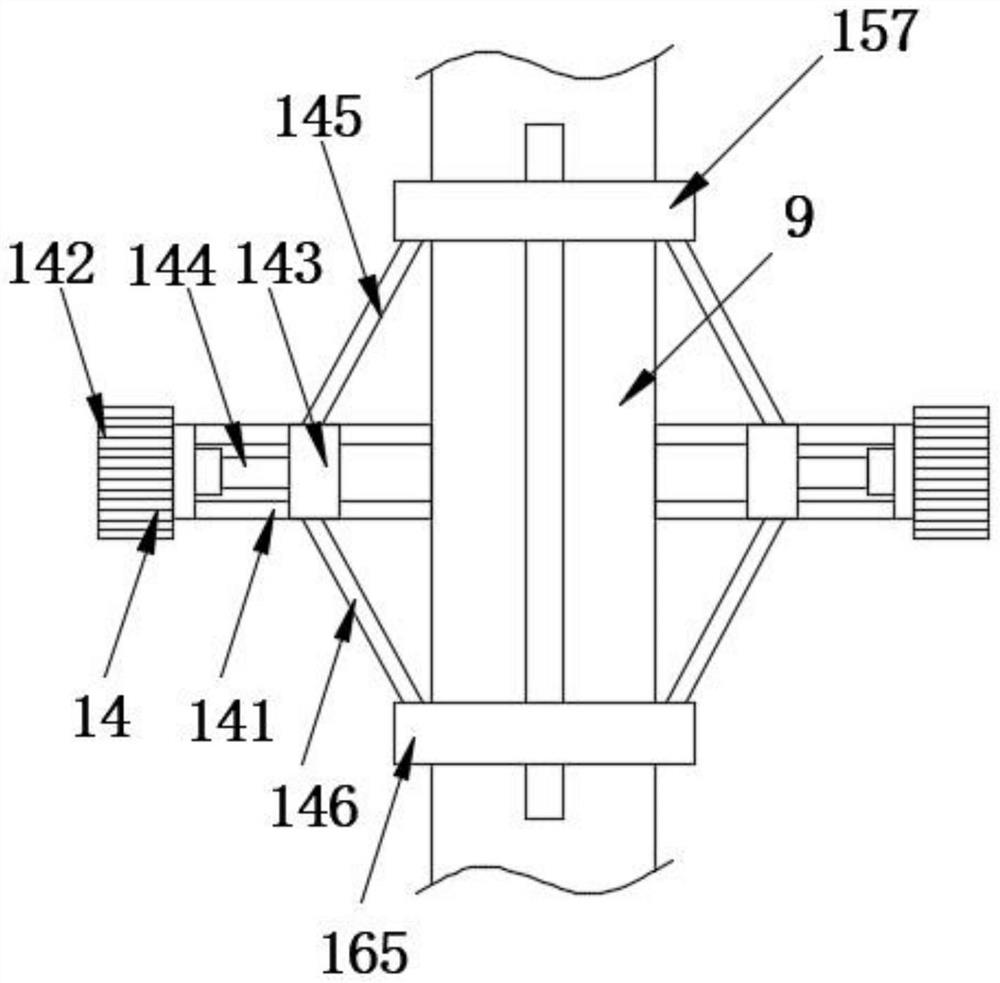

[0042] Such as figure 1 As shown, a lower slide 10 is arranged symmetrically inside the upper surface of the workbench 1, and recovery boxes 11 are symmetrically and fixedly connected to both sides of the workbench 1, and the recovery box 11 cooperates with the lower slide 10, when the upper surface of the workbench 1 When the waste material slides into the interior of the recovery box 11 from the lower plate 10, it is convenient for the recovery box 11 to carry out centralized recovery and treatment of the waste materials, thereby facilitating recycling and reuse. The lower end of the driving mechanism 14 is movably connected with a cleaning mechanism 16, and the cleaning mechanism 16 is positioned at the outside of center column 9, and cleaning mechanism 16 works synchronously with correction mechanism 15, as Figure 8 As shown, the cleaning mechanism 16 includes an annular jacket 161, the outer surface of the annular jacket 161 is symmetrically fixedly connected with a holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com