Granulator for drain board production and working method thereof

A technology of granulator and drainage board, which is applied in the direction of coating, etc., can solve the problems of particle adhesion, unfavorable heat dissipation, etc., and achieve the effect of uniform material without adhesion and prevention of material adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

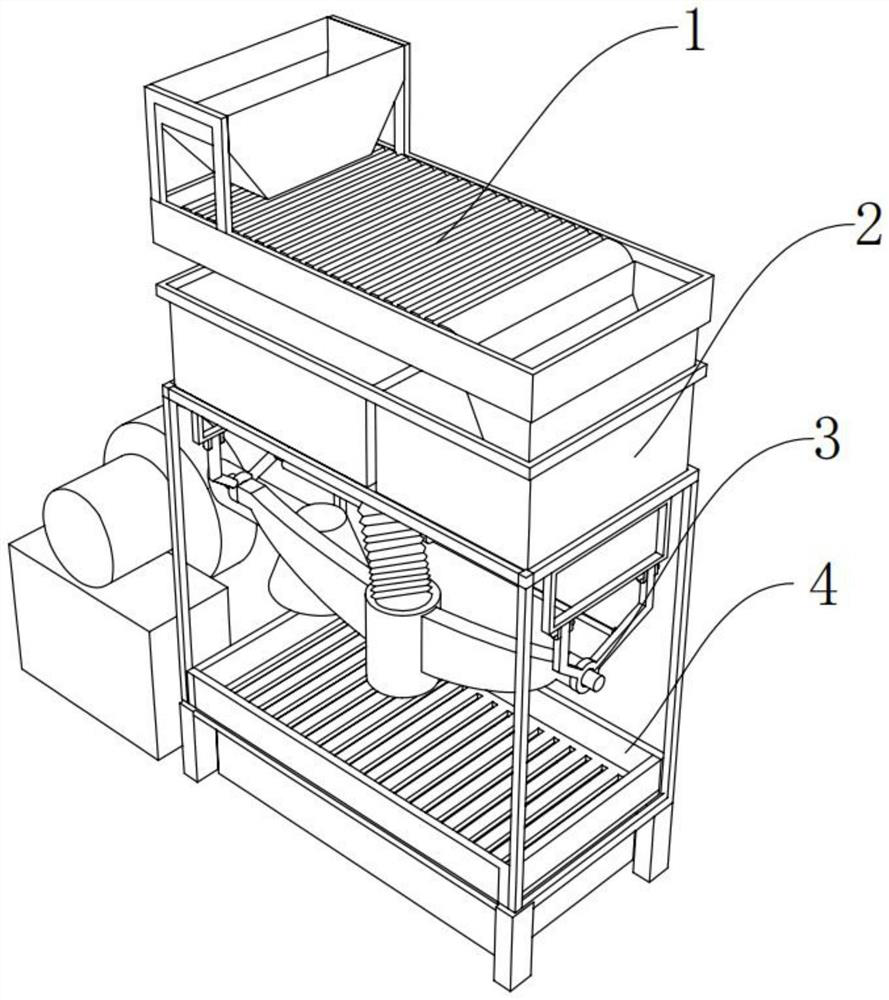

[0037] see Figure 1-5 Shown is a granulator for the production of drainage boards, where the drainage boards are made of polystyrene or polyethylene as raw materials, and the plastic bottom boards are stamped to form conical protrusions or ribs with a width of 1 ~3 meters, and the length is 4-10 meters or more, so a large amount of polystyrene or polyethylene raw materials are needed when producing drainage boards;

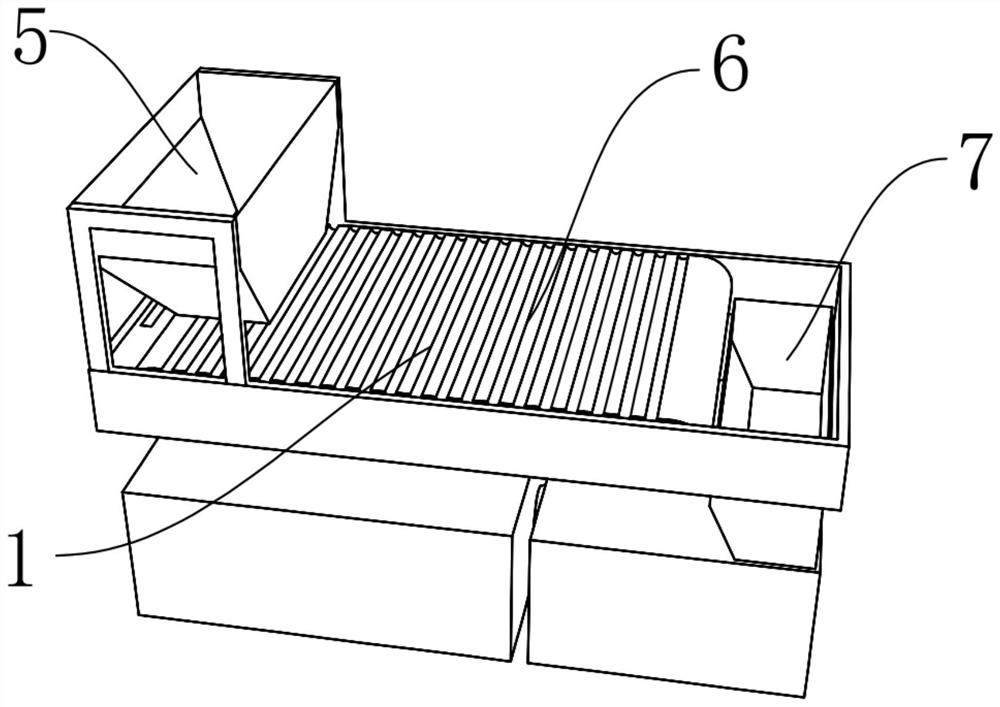

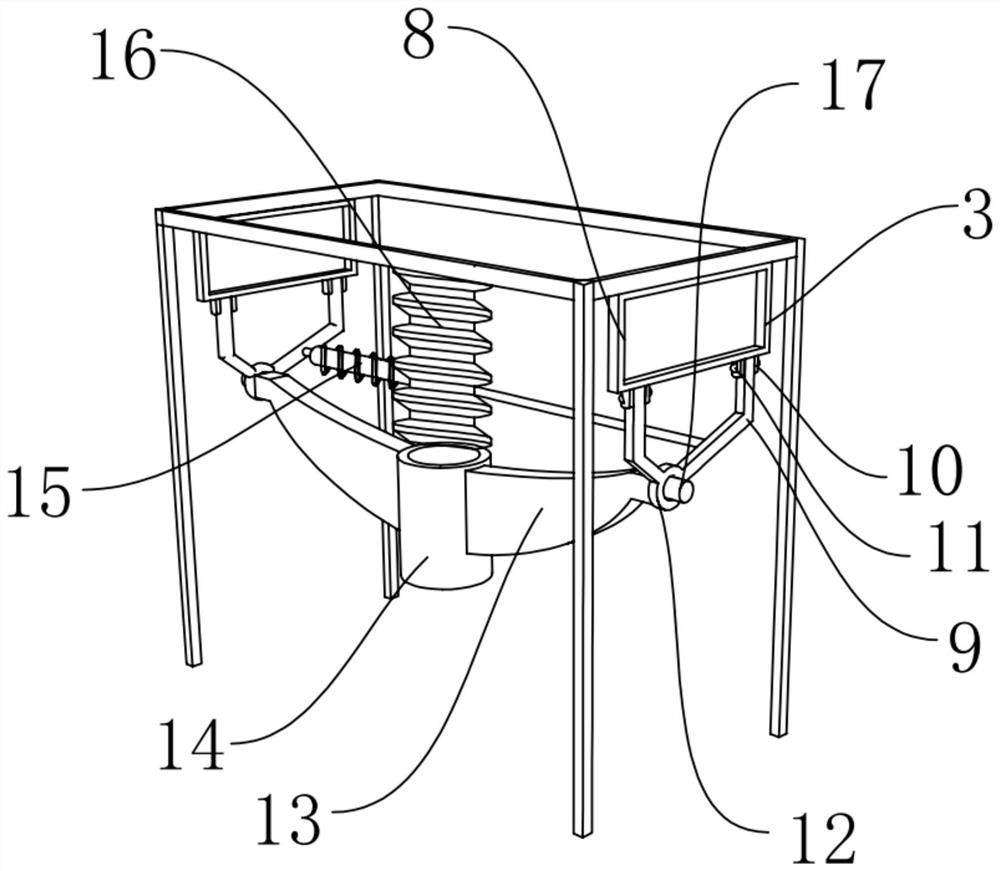

[0038] The application includes a granulator, wherein the granulator is a feeding assembly 1, a pelletizing assembly 2, a blanking assembly 3 and a discharging assembly 4 from top to bottom;

[0039] In some embodiments, the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com