Cloth embossment pattern forming and processing equipment

A technology for pattern forming and processing equipment, applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve the problems of uneven wrinkles and poor fabric forming, and achieve the effect of preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

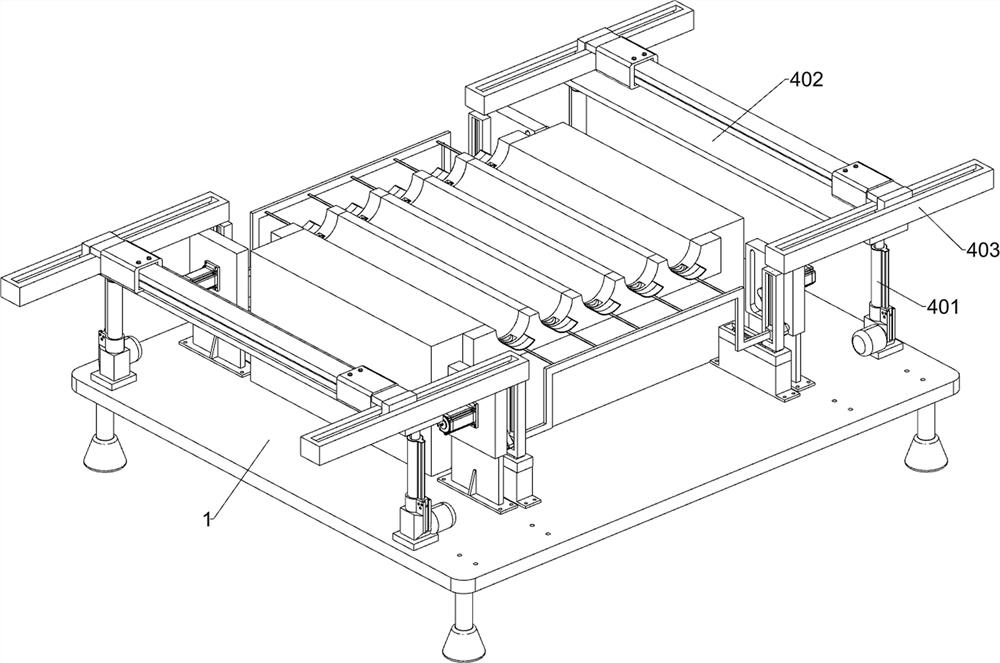

[0031] A cloth embossed pattern forming processing equipment, such as Figure 1-10 As shown, it includes a bottom frame 1, a mounting frame 2, a first fixed plate 3, a second fixed plate 4, a first fixed frame 5, a drive assembly, a pressing assembly and a removal assembly; the front part of the upper side of the bottom frame 1 is connected with Mounting frame 2; the rear side of the upper part of the mounting frame 2 is connected with the first fixed plate 3 and the second fixed plate 4 in turn, and the first fixed plate 3 is located in front of the second fixed plate 4; the middle part of the rear side of the mounting frame 2 is connected with the first fixed plate Frame 5; the rear side of the first fixed plate 3 and the rear side of the second fixed plate 4 are each equipped with a driving assembly; the lower part of the driving assembly is installed with a pressing assembly;

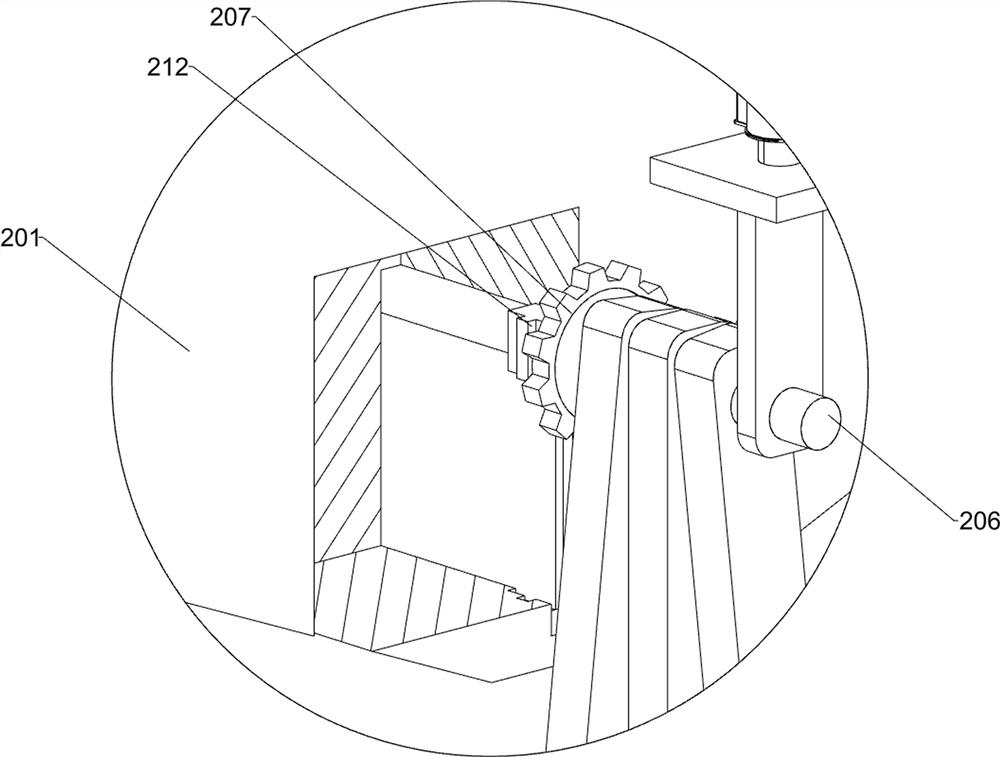

[0032] Wherein, the driving assembly at the front includes a first mounting plate 101, a main mo...

Embodiment 2

[0042] On the basis of Example 1, such as figure 1 and Figure 11-12 As shown, a clamping assembly is also included, and a clamping assembly is installed on the upper left part and the upper right part of the chassis 1 respectively, and the clamping assembly on the right includes a second electric push rod 401 and a sixth fixing plate 402 , the third limit slide rail 403, the electric slider 404, the electric clip 405 and the return spring 406; the upper left part and the upper right part of the bottom frame 1 are fixedly connected with two second electric push rods 401; the front and rear are adjacent The telescopic ends of the two second electric push rods 401 are fixedly connected with a sixth fixing plate 402; the upper front and upper rear parts of the two sixth fixing plates 402 are fixed with a third limit slide rail 403; An electric slider 404 is slidably connected in each third limit slide rail 403; an electric clip 405 is fixedly connected between the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com