Synchronous collecting device for alumite

A collection device, anodized aluminum technology, applied in printing, rotary printing machines, printing machines, etc., can solve problems such as bumps, impact on hot stamping effects, and damage to anodized aluminum materials, so as to quickly relieve impact, stabilize lifting, The effect of quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

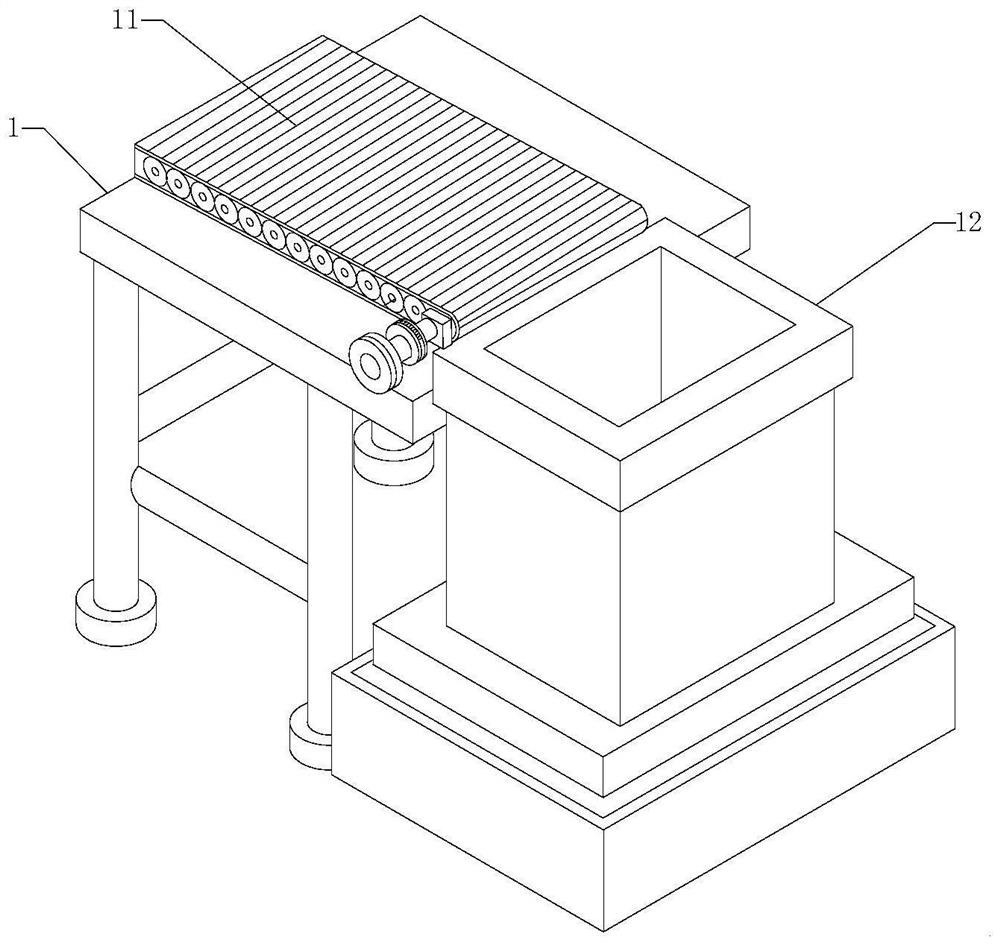

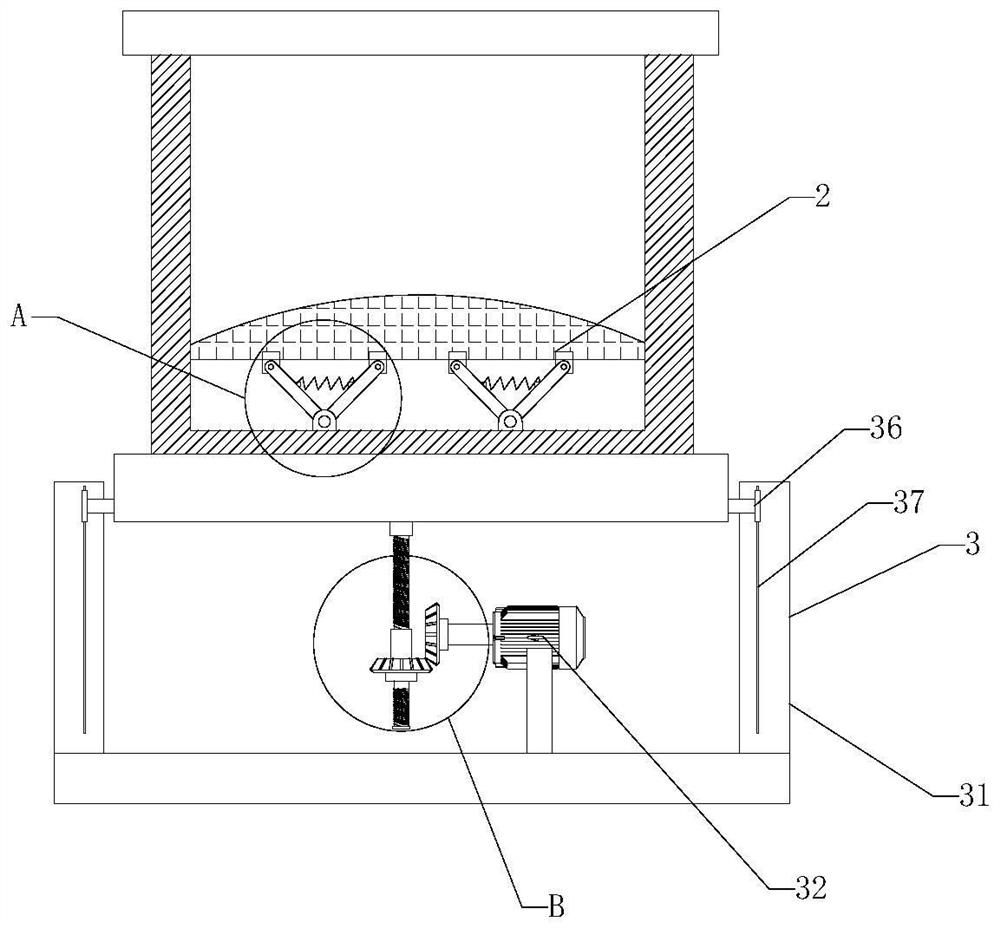

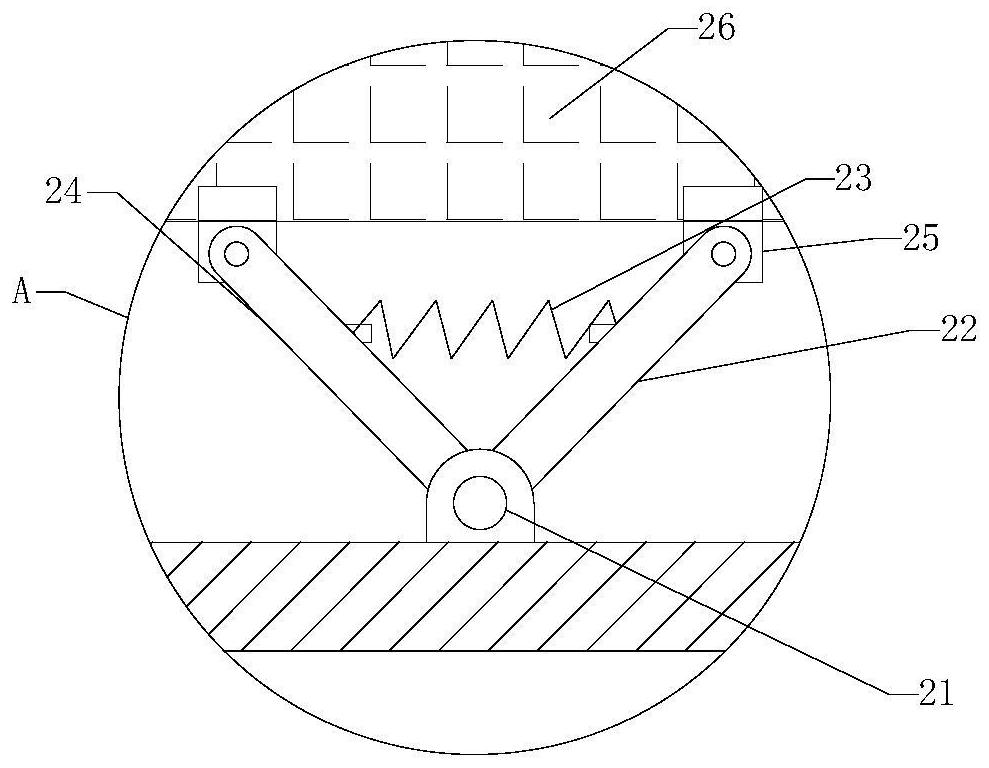

[0024] see Figure 1-4 As shown, a synchronous collection device for anodized aluminum includes a device main body 1; the device main body 1 includes a transmission assembly 11 and a collection box 12; the transmission assembly 11 is movably connected to the upper end of the device main body 1; the collection box 12 is set At the front end of the device main body 1; the inside of the device main body 1 is provided with an anti-collision mechanism 2; the anti-collision mechanism 2 includes a movable shaft 21, a first folding rod 22, a shock spring 23, a second folding rod 24, and a movable block 25 and cushion 26; the movable shaft 21 is fixedly connected to the inside of the collection box 12; the first folding rod 22 is movably connected to the upper end of the movable shaft 21; the shock spring 23 is fixedly connected to the first folding rod 22 One end; the second folding rod 24 is movably connected to the upper end of the movable shaft 21; the movable block 25 is movably c...

Embodiment 2

[0037] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, the upper end of the device main body 1 is equipped with a limiting component 4; the limiting component 4 includes a first positioning plate 41 and a second positioning plate 42; The first positioning plate 41 and the second positioning plate 42 are fixedly installed at both ends of the transmission assembly 11; during operation, by installing the first positioning plate 41 and the second positioning plate 42 at the two ends of the transmission assembly 11, the electrification The aluminum is shielded during transmission, which achieves the function of positioning transmission, prevents transmission deviation, and improves transmission stability.

[0038] Working principle, through the structural design of the anti-collision mechanism 2 installed inside the collection box 12, the anodized aluminum is synchronously transmitted to the inside of the collection box 12 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com