Article processing system with direct butt joint positioning device and method thereof

A positioning device and processing system technology, applied in the field of storage, can solve problems such as structural defects, complex structure, and increased cost of three-dimensional warehouses, and achieve the effects of improving operating efficiency and reducing hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

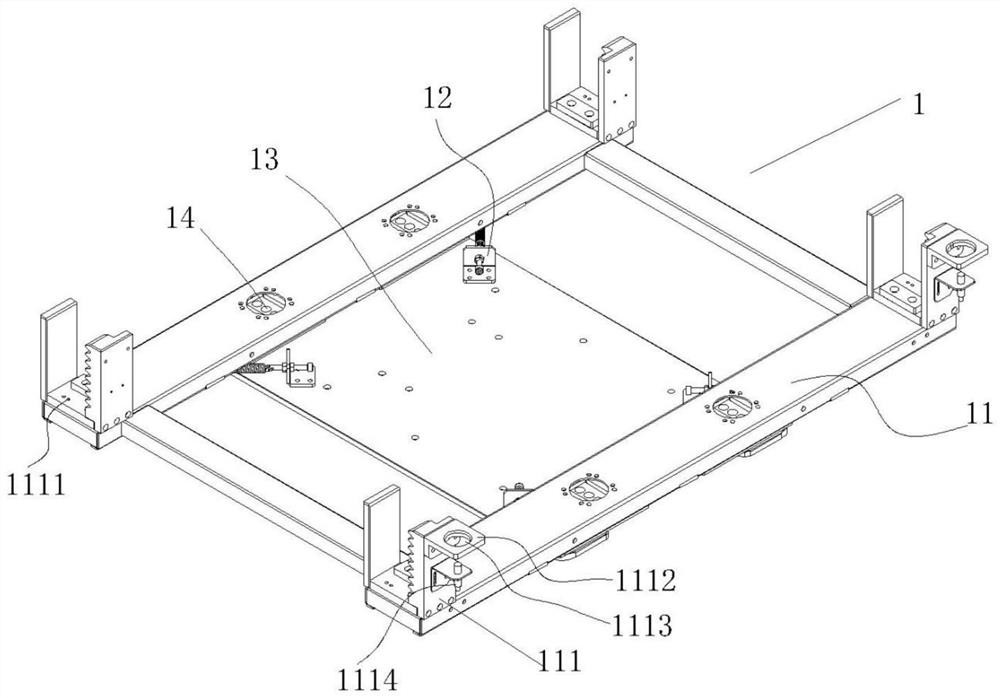

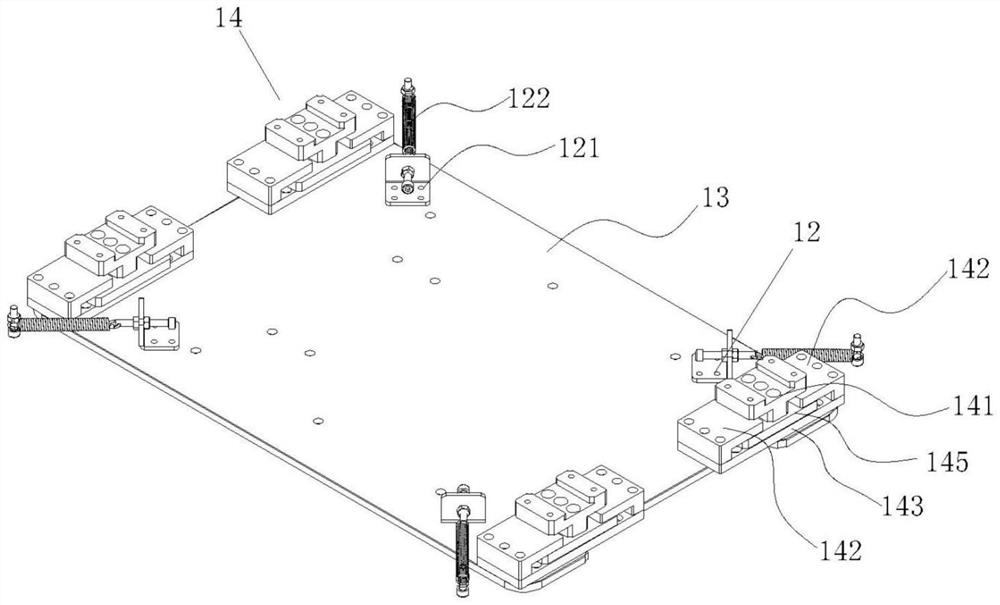

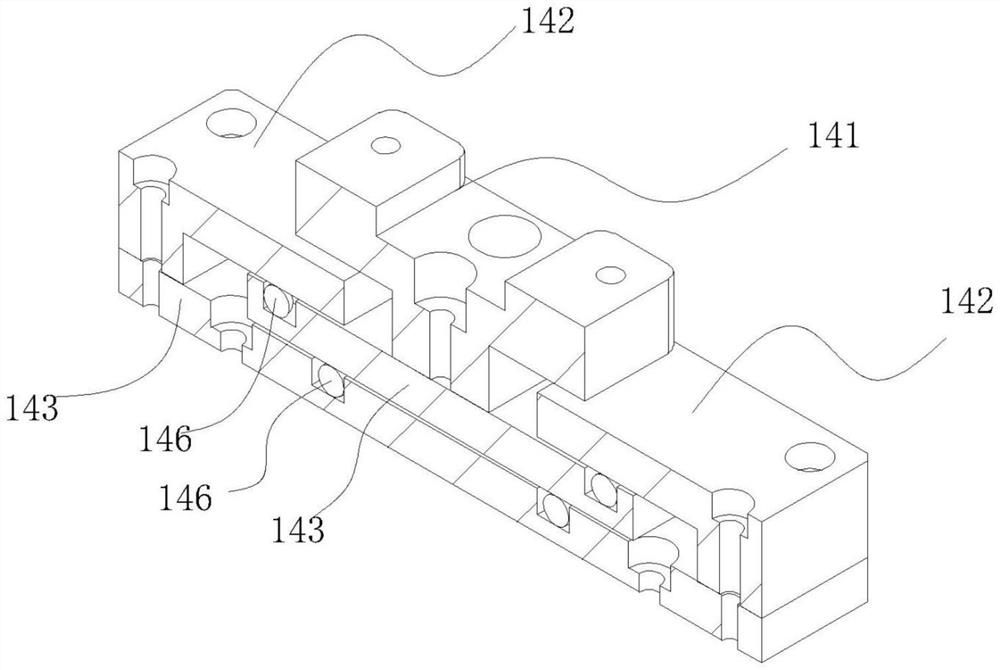

[0042] The article processing system with a direct docking positioning device includes an article access system 4, a horizontal motion robot 2 and a vertical motion robot 3; wherein the horizontal motion robot 2 is connected to the vertical motion robot 3 through direct docking positioning, and the horizontal motion robot 2 is used to transport the vertical motion robot. Robot 3. In this embodiment, the direct docking positioning and flexible docking device and the docking track constitute the flexible connection mechanism 1, and the horizontal moving robot 2 and the vertical moving robot 3 constitute the horizontal moving device.

[0043] Such as figure 1 , the flexible connection mechanism 1 includes a connection frame 11, a flexible adjustment structure 12, a mounting plate 13 and a floating seat assembly 14, wherein the connection frame 11 is rectangular and the middle part is hollow, and the four corners are protruding, and the four corners are used for docking with the v...

Embodiment 2

[0057] The control method for operating the article processing system with a direct docking positioning device in Embodiment 1 includes the following steps:

[0058] S100, the horizontal motion robot 2 accepts the instruction and travels to the first designated position of the item access system 4;

[0059] This step can be through the common control system in the factory. The first designated position is the horizontal movement robot 2 to go to the corresponding position with the help of the vertical movement robot 3.

[0060] S200, realize the positioning of the horizontal motion robot 2 through the cooperation of the first positioning part 431 and the positioning hole 1113;

[0061] In this step, the horizontal motion robot 2 pushes the mounting plate 13 up, so that the first positioning portion 431 on the shelf body is inserted into the positioning hole 1113 to achieve positioning.

[0062] S300, the vertical motion robot 3 located at the designated position receives an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com