Esterification product for preparing water reducing agent, preparation method of esterification product, high-workability polycarboxylic acid water reducing agent and preparation method of high-workability polycarboxylic acid water reducing agent

A technology of water reducer and polycarboxylic acid, which is applied in the field of high workability polycarboxylate water reducer and its preparation, can solve the problems of water reducer performance reduction, etc., achieve improved anticorrosion performance, excellent high temperature anticorrosion performance, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

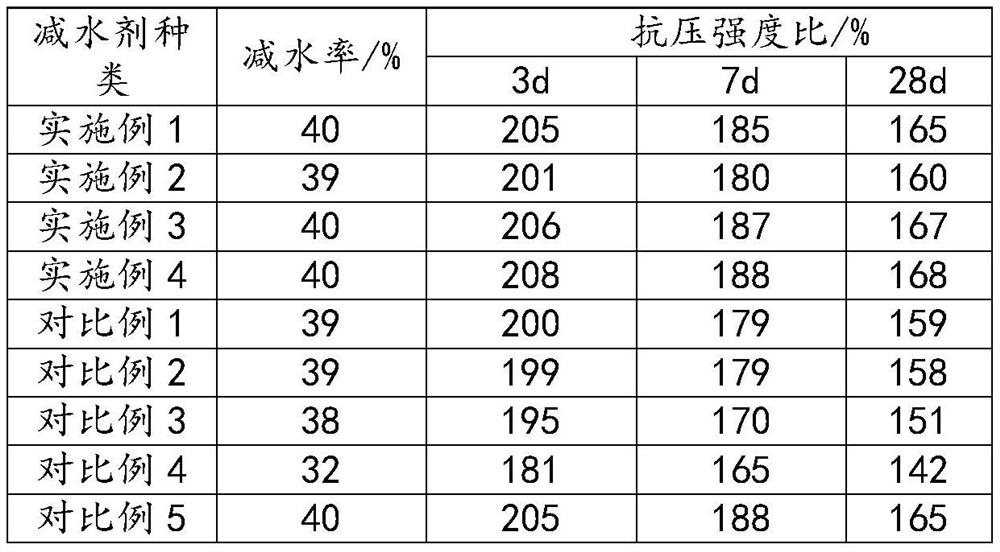

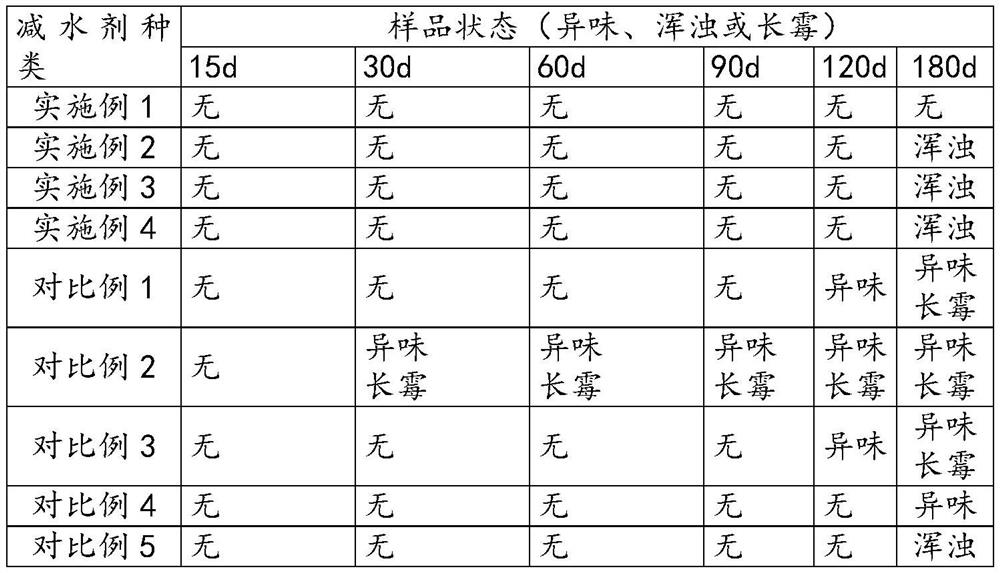

Examples

Embodiment 1

[0038](1) Preparation of esterification product: Mix 150.00g of acrylic acid, 140.00g of phenoxyethanol and 2.00g of hydroquinone, under the protection of nitrogen, heat up to 90°C, then add 1.30g of p-toluenesulfonic acid, keep warm for 2.0h During the period, the water was removed by vacuuming or nitrogen with water, and after the reaction was completed, it was cooled to room temperature, and the obtained mixture was the esterification product A-1.

[0039] (2) Copolymerization reaction: 300.00g molecular weight is 2-methallyl polyethylene glycol of 2400, 100g acrylic acid and the esterification product of the methoxy polyethylene glycol of 1200 molecular weight, 8.00g esterification product A -1. Add 3.00g of monomethyl fumarate, 0.08g of ferrous sulfate heptahydrate, 10.00g of sodium hypophosphite and 278.00g of water into the reactor, turn on the agitator, wait until the materials are evenly mixed, and start to add dropwise acrylic acid aqueous solution ( Among them, 45.0...

Embodiment 2

[0041] (1) Preparation of esterification product: mix 180.00g methacrylic acid, 140.00g phenoxyethanol and 2.50g 4-hydroxyl-2,2,6,6-tetramethylpiperidine-1-oxyl free radical, temperature to 90°C, then added 1.30g of concentrated sulfuric acid, and kept the temperature for 2.5 hours. During this period, the water was removed by evacuating or flowing nitrogen with water. After the reaction was completed, it was lowered to room temperature, and the obtained mixture was the esterification product A-2 .

[0042] (2) Copolymerization reaction: 300.00g molecular weight is 2400 3-methyl-3-butene-1-polyethylene glycol, 30g acrylic acid and molecular weight are the esterification product of 1200 methoxypolyethylene glycol, 30g The esterification product of methacrylic acid and methoxypolyethylene glycol with a molecular weight of 1200, 4.00g of esterification product A-2, 4.00g of diethyl maleate, 0.09g of ferrous sulfate heptahydrate and 285.00g of water were added In the reactor, ope...

Embodiment 3

[0044] (1) Preparation of esterification product: 100.00g maleic anhydride, 70.00g acrylic acid, 150.00g phenoxyisopropanol, 1.00g4-hydroxyl-2,2,6,6-tetramethylpiperidine-1-oxygen free base and 1.0g of hydroquinone, under the protection of nitrogen, the temperature was raised to 75°C, and then 1.30g of p-toluenesulfonic acid was added, and the reaction was kept for 2.5h. After cooling down to room temperature, the obtained mixture is the esterification product A-3.

[0045] (2) Copolymerization reaction: 300.00g molecular weight is the esterification product of 4-hydroxybutyl vinyl polyoxyethylene base ether of 3000, 50g acrylic acid and molecular weight are the methoxypolyethylene glycol of 600, 50g acrylic acid and molecular weight are 1200 methoxypolyethylene glycol esterification product, 6.00g esterification product A-3, 1.00g monomethyl fumarate, 2.00g diethyl maleate, 0.09g ferrous sulfate heptahydrate and 280.00 g of water was added to the reactor, and the stirrer was...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap