Two-stage heat pipe type solar air heater

An air heater, solar energy technology, applied in solar collectors, solar heating systems, solar thermal energy and other directions, can solve the problems of high resistance, low efficiency, low temperature of hot air, etc., to reduce resistance, high heat transfer rate, The effect of enhancing the heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below with reference to the accompanying drawings and specific embodiments.

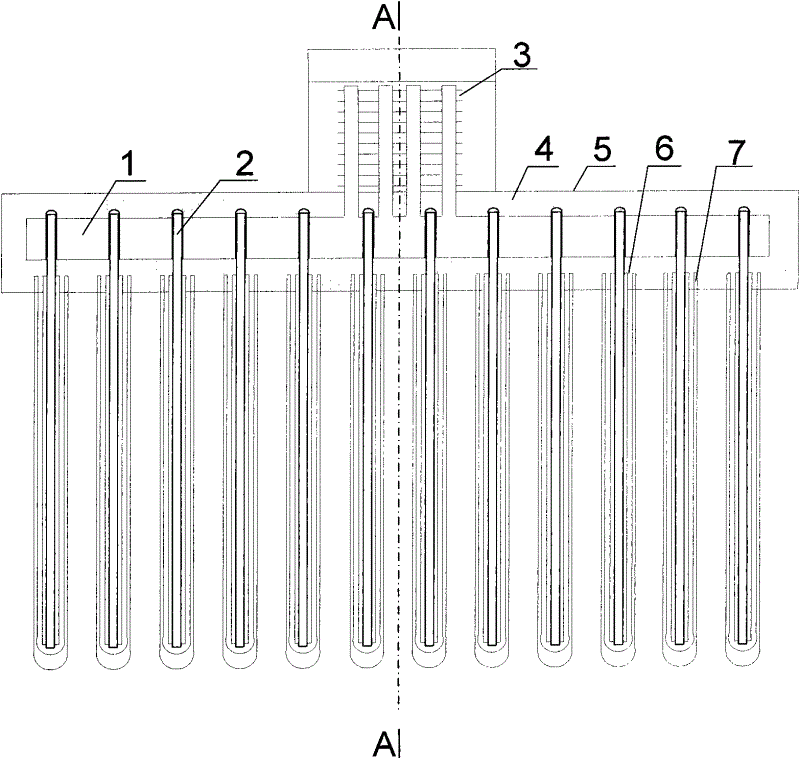

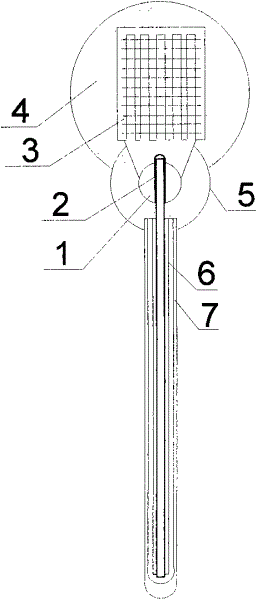

[0026] figure 1 Shown is a schematic diagram of the structure of a two-stage heat pipe vacuum tube solar air heater. like figure 1 As shown, the present invention mainly includes a combined heat pipe 1, a straight pipe type heat pipe 2, an air flow channel 3, a thermal insulation layer 4, a shell 5, an inner fin 6, a coated vacuum tube 7, and the like. Taking the vertical placement of the heater as an example, the coated vacuum tube 7 is placed at the lowermost end of the heater, a straight-tube heat pipe 2 is inserted in the coated vacuum tube 7, and a ring-shaped metal insert is inserted between the inner tube of the coated vacuum tube 7 and the straight-tube heat pipe 2. The fins 6 are used to enhance heat exchange, and the upper end of the coated vacuum tube 7 is a joint frame formed by a thermal insulation layer 4 and an outer shell 5. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com