Ampoule bottle printed word defect detection method based on image registration

An image registration and defect detection technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of judgment error, quality qualification standards cannot be completely unified, and high cost, so as to reduce feature matching errors and improve Detection results, the effect of eliminating image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

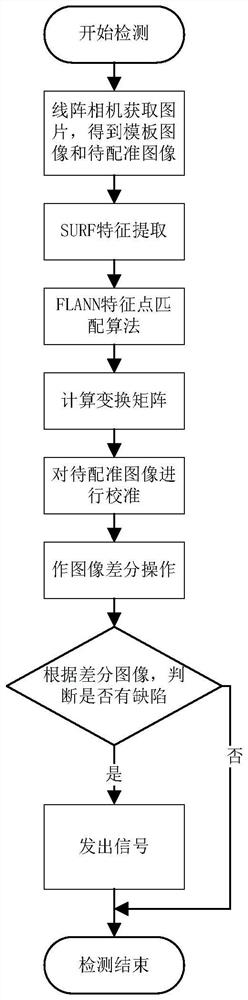

[0039] Such as figure 1 As shown, an image registration-based defect detection method for ampoule printed characters includes the following steps:

[0040] Step 1: Use a line array industrial camera to capture the printed word image of the ampoule bottle, and obtain the template image and the image to be registered; Step 2: Use the SURF algorithm to extract and describe the feature points of the template image, and perform feature points on the image to be registered Extraction and feature point description; Step 3: Use the FLANN matching algorithm for feature point matching; Step 4: Calculate the transformation matrix that maps the image to be registered to the template image according to the matched feature point pairs; Step 5: Convert the image to be registered The image is calibrated through the transformation matrix to eliminate image distortion; Step 6: Make an image difference between the template image and the calibrated image to be registered to obtain a difference im...

Embodiment 2

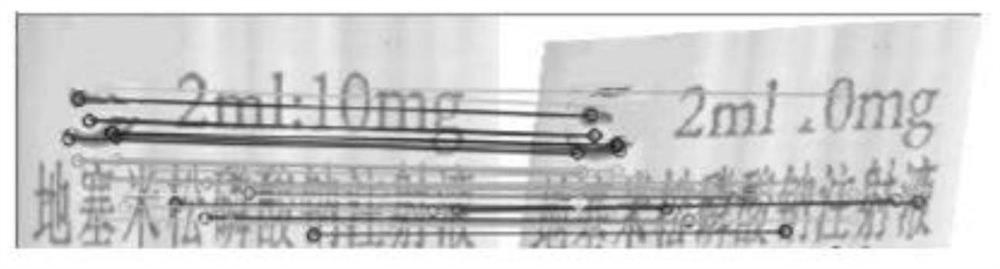

[0042] A method for detecting defects of printed characters on ampoules based on image registration, including the following steps: Step 1: Use a linear array industrial camera to collect images of printed characters on ampoules, and obtain template images and images to be registered, such as figure 2 Shown; Step 2: Use the SURF algorithm to perform feature point extraction and feature point description on the template image, perform feature point extraction and feature point description on the image to be registered, and shrink the input image to 250*200 before feature point extraction size; step 3: use the FLANN matching algorithm for feature point matching, such as image 3 As shown, after the feature points are matched, the Euclidean distance of each feature point pair is calculated, and the value of 2 times the minimum Euclidean distance is set as the threshold, and the feature point pairs whose Euclidean distance is greater than the set threshold are eliminated; Step 4: ...

Embodiment 3

[0044] Such as figure 1 As shown, an image registration-based defect detection method for ampoule printed characters includes the following steps:

[0045] Step 1: Use a line-scan industrial camera to capture the image of the printed word on the ampoule bottle, and obtain the template image and the image to be registered;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com