Large-diameter polar field coil wound by hollow rectangular copper conductor and winding method

A winding method and technology for copper conductors, applied in coil manufacturing, coils, electrical components, etc., can solve the problems of large contact resistance and low current carrying, and achieve the effect of reducing stray magnetic fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

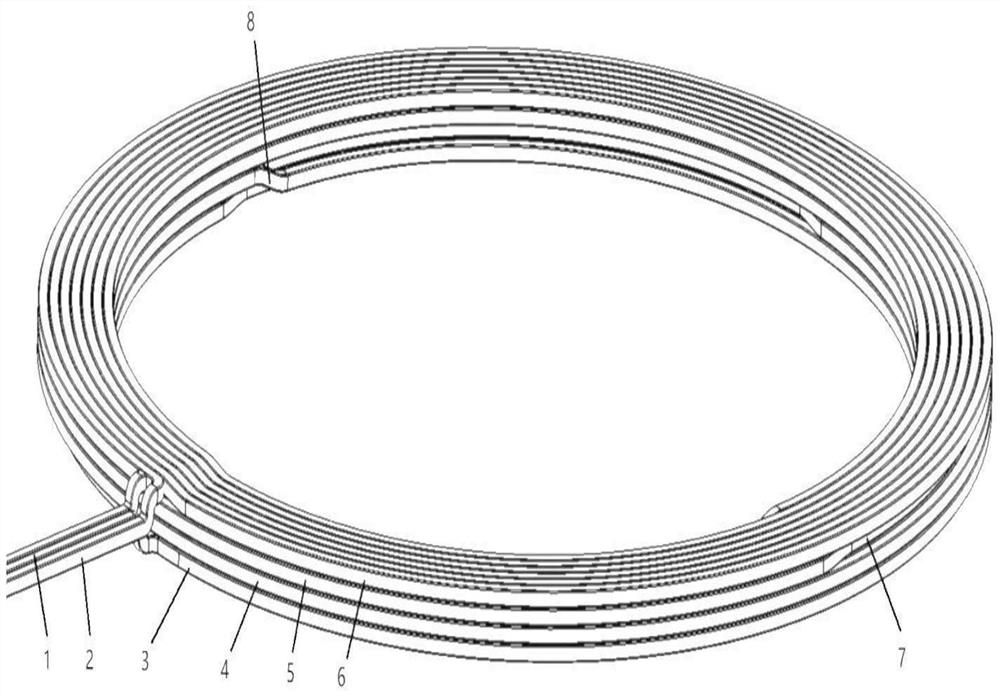

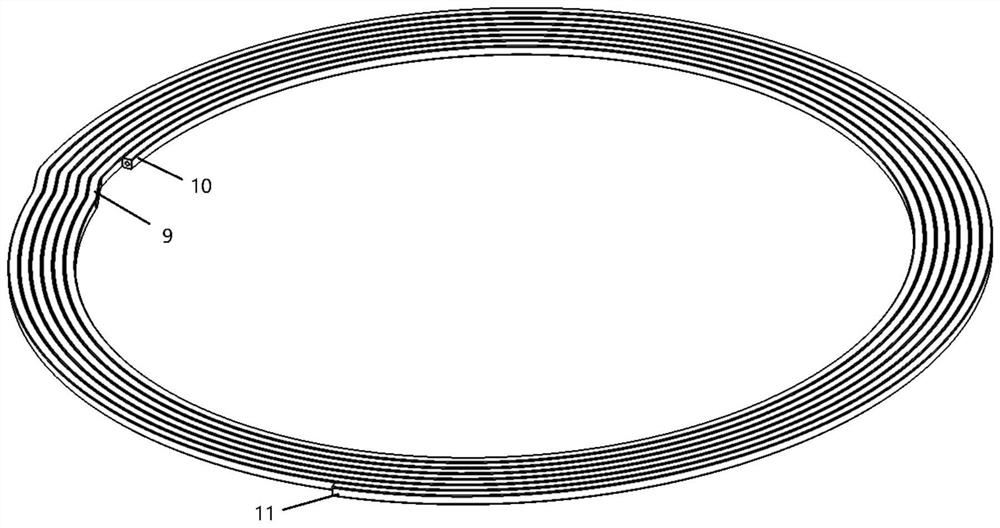

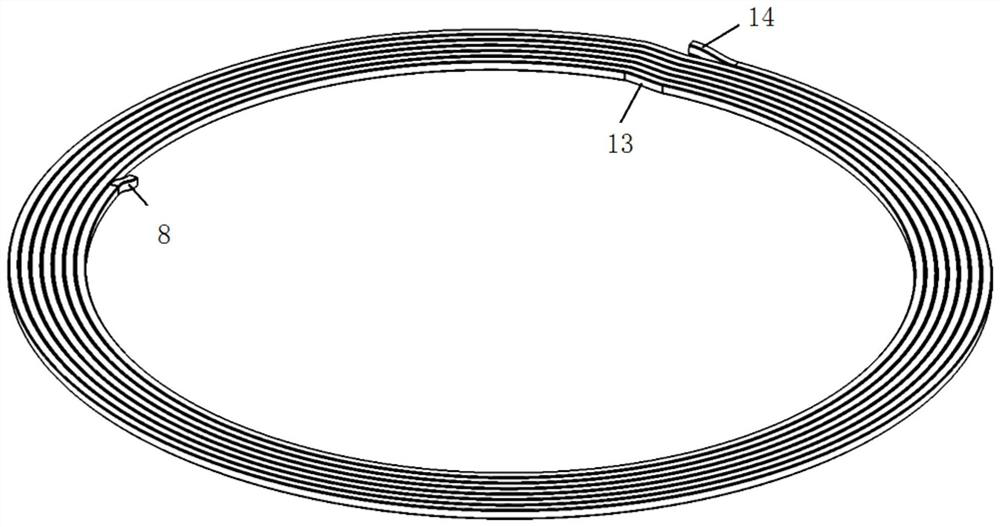

[0026] like figure 1 As shown, the large-diameter poloidal field coil wound by a hollow rectangular copper conductor is made of a hollow rectangular copper conductor with a large cross-section using a disk winding method, and is made by winding n-layer coil conductors from top to bottom, wherein The set winding number of hollow rectangular copper conductors of each layer of coil conductors is m turns. When winding, n layers of coil conductors are stacked up and down and the head and tail ends of the hollow rectangular copper conductors of each adjacent layer are welded together. Both n and m are positive integers.

[0027] like figure 1 As shown, the first layer of coil conductor 3 is located at the uppermost layer, followed by the second layer of coil conductor 4, the third layer of coil conductor 5, the fourth layer of coil conductor 6, and so on; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com