Fabricated building curtain wall

A prefabricated and architectural technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of inconvenient quick disassembly and assembly of a single external curtain wall, inconvenient installation, and difficult installation, so as to achieve easy and stable installation without traces and guarantee smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

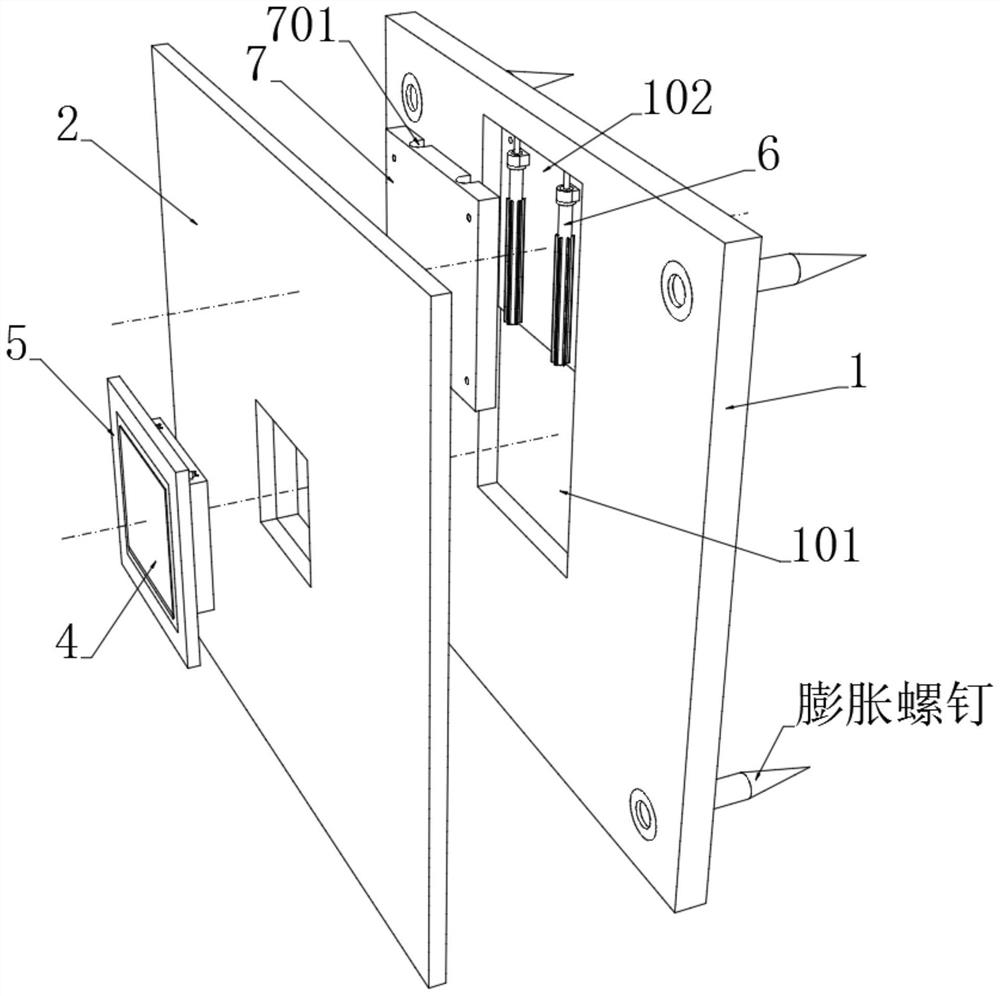

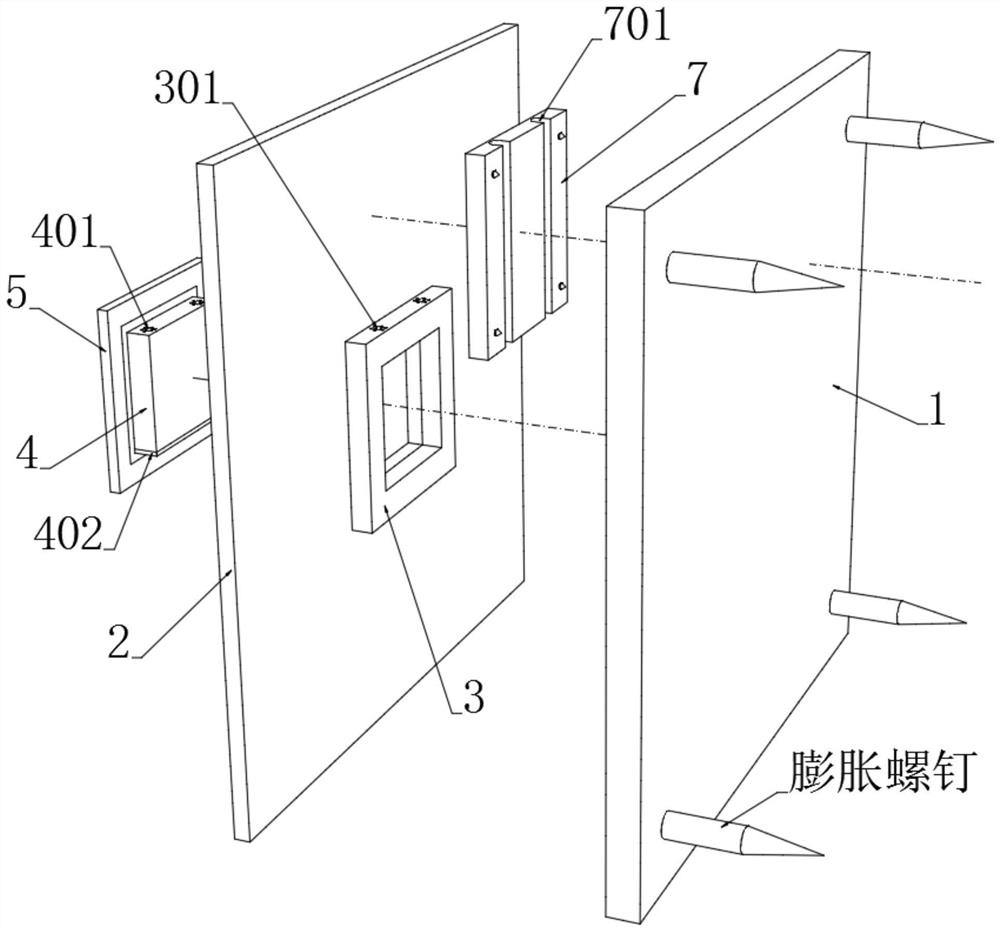

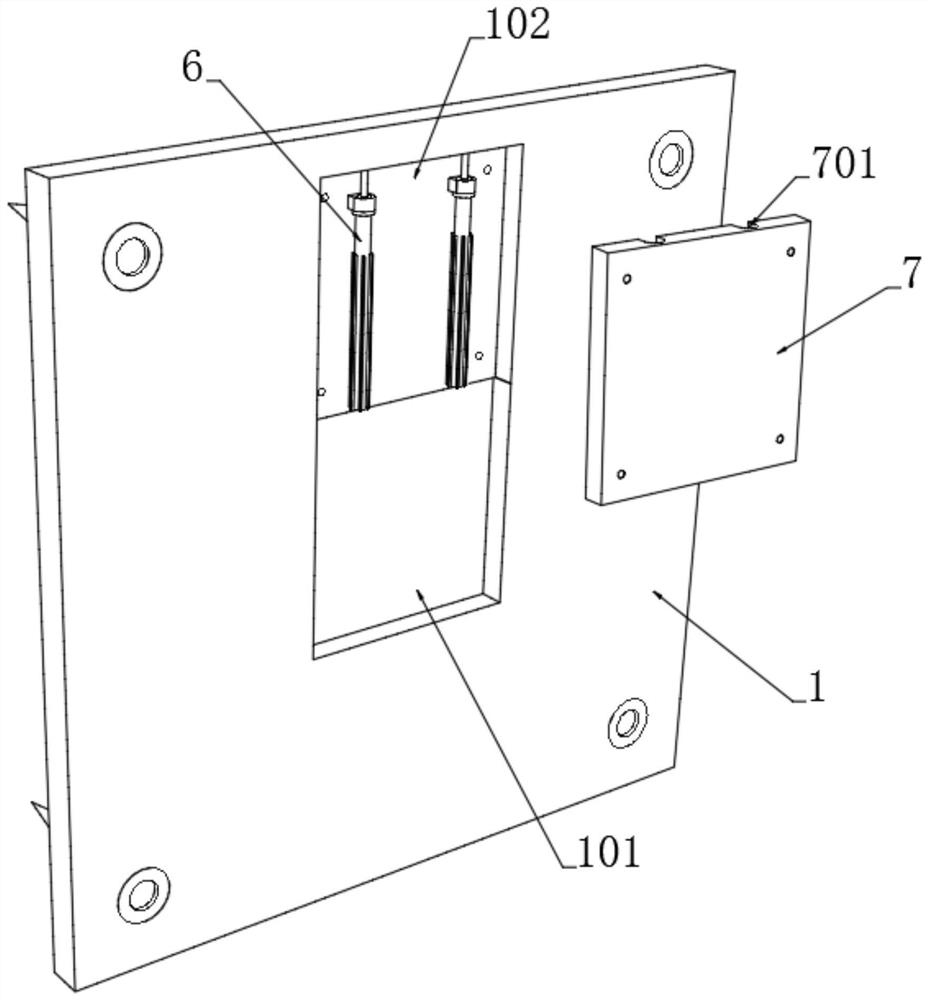

[0046] see Figure 1-4 , a prefabricated building curtain wall, comprising an inner frame 1 and an outer curtain wall 2, the middle end wall of the outer curtain wall 2 facing the inner frame 1 side is fixedly bonded with a hollow butt plate 3, and the outer curtain wall 2 is provided with a hollow The activity cavity corresponding to the position of the docking plate 3, the movable cavity is provided with a hollow docking plate 3, the outer end of the assembly plate 4 is exposed outside the outer curtain wall 2, the inner end of the assembly plate 4 is movably connected with the inner wall of the hollow docking plate 3, and the assembly plate 4. The upper sleeve is provided with a limit sleeve 5 that is offset against the outer end wall of the outer curtain wall 2. The inner end of the limit sleeve 5 is provided with a flexible sleeve that is covered on the outer end wall of the assembly plate 4. Before installation, the limit sleeve 5 is set on the assembly plate 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com