Mortar spraying operation device and mortar spraying method for real estate decoration

A technology for operating equipment and real estate, which is applied in clay preparation equipment, cement mixing equipment, chemical instruments and methods, etc., can solve problems such as equipment damage or blockage, and cannot be found in time, and achieve the effect of avoiding impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

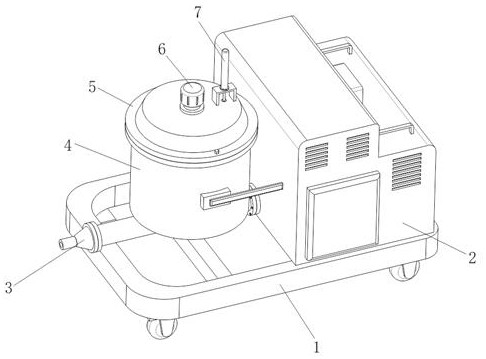

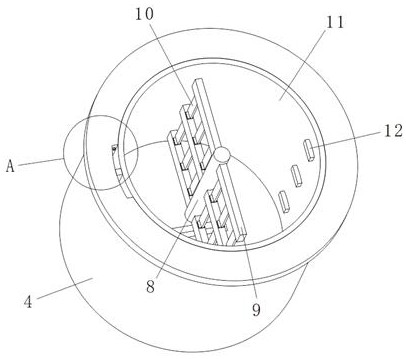

[0029] The invention provides a technical solution: a mortar spraying operation device for real estate decoration, please refer to figure 1 , including: car body 1 and spraying machine body 2, spraying machine body 2 refers to the mortar spraying machine;

[0030] The spraying machine body 2 is installed on the right side wall of the top of the car body 1, and the left side wall of the spraying machine body 2 is equipped with a conveying mechanism 3. The conveying mechanism 3 refers to a screw conveying mechanism. The feeding port of the mechanism 3 communicates with the inner cavity of the material barrel 4, and the conveying mechanism 3 is driven by the sprayer body 2 to work and rotate, and the mortar in the material barrel 4 is discharged. The mortar spraying machine is an existing equipment, and its working method also belongs to The existing technology will not be described in detail here, and the electrical equipment involved in the device is electrically connected to t...

Embodiment 2

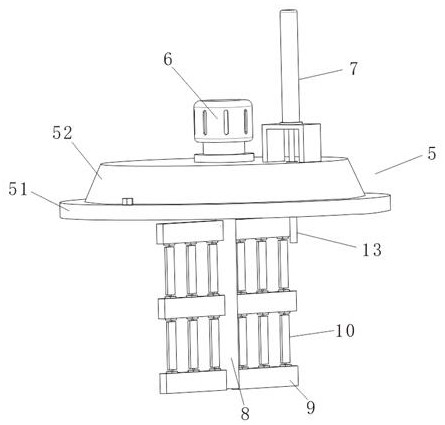

[0037] see figure 1 with image 3, on the basis of Embodiment 1, the bung 5 includes an installation cover 51 installed on the top wall of the barrel 4, the top wall of the installation cover 51 is rotatably installed with a rotation cover 52, the driving motor 6 is connected with the installation cover 51, and the rotation cover 52 The rotation will not rotate together with the drive motor 6, and the rotating cover 52 will change the position of the detection rod 13 to detect the mortar in other positions. There is a detection rod 13, a frame is installed on the top wall of the rotating cover 52, and an electric push rod 7 is installed on the top wall of the frame, the bottom moving end of the electric push rod 7 is connected with the top wall of the detection rod 13, and the electric push rod 7 is connected with the push switch 15 1. The contact switch is electrically connected. When the push switch 15 or the contact switch is pressed, the electric push rod 7 will work, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com