Flushing head, negative pressure sand washing device with flushing head and using method of negative pressure sand washing device

A technology of flushing head and negative pressure generator, which is applied in wellbore flushing, earthwork drilling, wellbore/well components, etc. It can solve the problems of polluted reservoirs, low sand washing efficiency, poor sand return effect, etc., and achieves portable Strong sanding ability, strong sand washing ability, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: a kind of rinse head

[0052] Embodiment 1 provides a rinse head, the structure of which will be described in detail below.

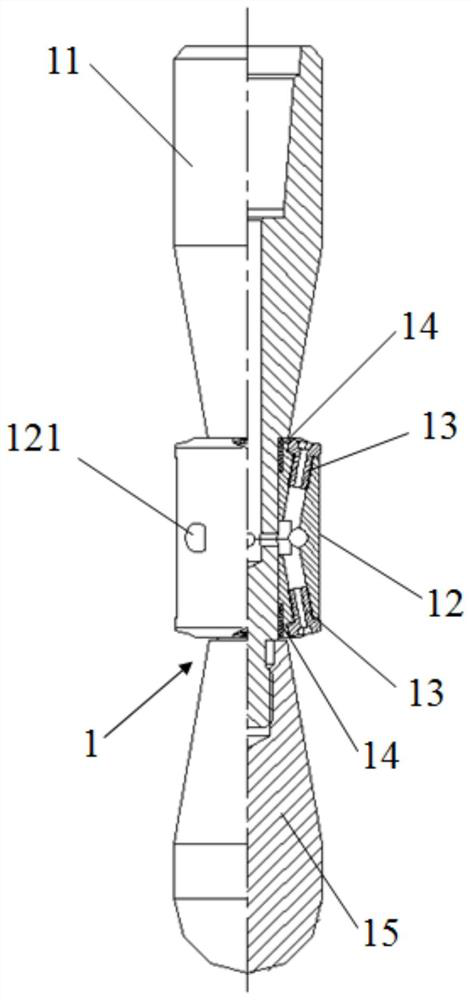

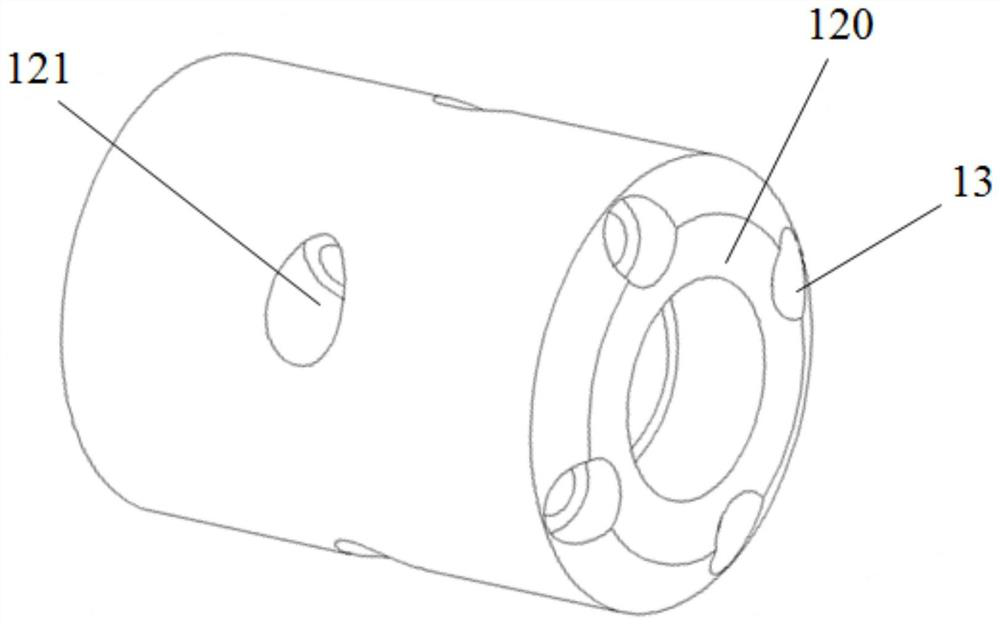

[0053] refer to figure 1 , the flushing head 1 includes a connecting pipe 11, a rotating sleeve 12, several nozzles 13, two sealing strips 14 and a guide head 15,

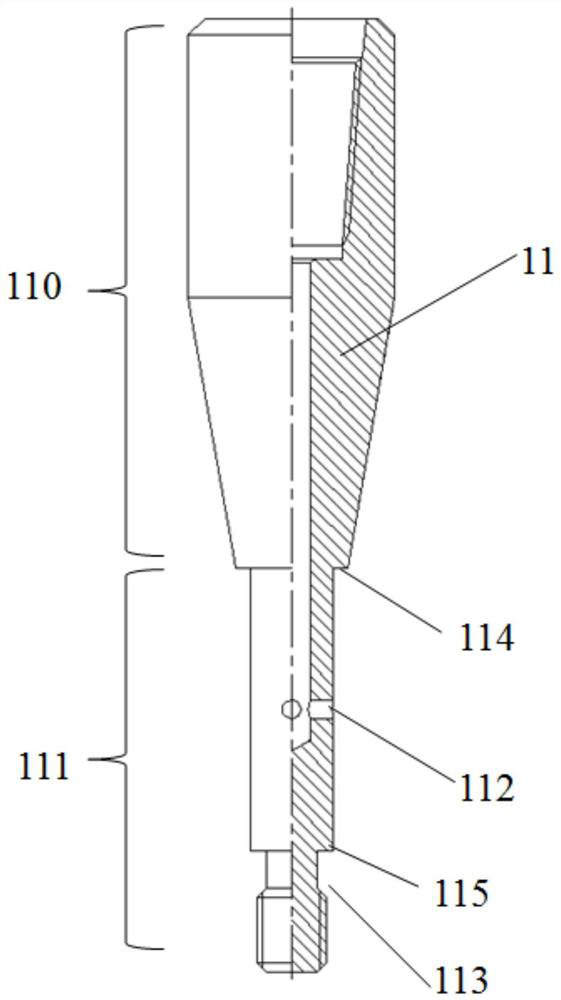

[0054] refer to figure 2 , the connecting pipe 11 comprises a docking portion 110 and a liquid spraying portion 111, the upper end of the inner pipe of the docking portion 110 is large, and the lower end is small, and the internal pipe of the liquid spraying portion 111 is a cylindrical shape with equal cross-sections, and the bottom end of the docking portion 110 is connected to the liquid spraying portion. The part 111 is integrally formed in fixed connection, and the internal pipe of the docking part 110 and the internal pipe of the liquid spraying part 111 communicate with each other to form the internal pipe of the connecting pipe 11; the rotating sleeve 12 is se...

Embodiment 2

[0063] Embodiment 2: A negative pressure sand washing device

[0064] Embodiment 2 provides a negative pressure sand washing device, which is used in deep water wells to be repaired, and includes the flushing head 1 of Embodiment 1, and its structure will be described in detail below.

[0065] refer to Figure 7 , the negative pressure sand washing device also includes a tube core assembly 2 and a casing assembly 3,

[0066] refer to Figure 8 , the tube core assembly 2 includes an upper double-walled oil pipe 21, a negative pressure generator 24, a sealed flow divider 25 and a lower double-walled oil pipe 22 arranged in sequence from top to bottom,

[0067] Both the upper double-wall oil pipe 21 and the lower double-wall oil pipe 22 are double-layer pipe structures formed by the inner oil pipe 201 sleeved on the outer oil pipe 202;

[0068] The outer oil pipe 202 of the upper double-wall oil pipe 21 is provided with a gas-liquid mixer 23 inside, and the liquid inlet of the...

Embodiment 3

[0079] Example 3: A method of using a negative pressure sand washing string device

[0080] Embodiment 3 provides a method of using a negative pressure sand washing string device, using the negative pressure sand washing string device provided in Embodiment 2, operating in a deep water well to be repaired, refer to Figure 11 and 12 , the method includes the following steps:

[0081] Step S1: Determine the deepwater well to be repaired, and sequentially run the screen 33, production casing 32 and production tubing 31 into the deepwater well to be repaired to form the casing assembly 3;

[0082] Among them, there is sedimentary sand 34 at the bottom of the deepwater well to be repaired, the screen 33 extends downward to the sedimentary sand 34, the production casing 32 is connected with the screen 33, the production tubing 31 is arranged inside the production casing 32, and the production The casing 32 and the production tubing 31 are separated by a plurality of packers 35 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com