Rotary air outlet device

A kind of air outlet device and rotary technology, which is applied in the direction of injection device, dry gas arrangement, dryer, etc., can solve the problems of low efficiency, high labor cost, large air outlet area, etc., and achieve good use effect, adjustment and locking Convenience and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

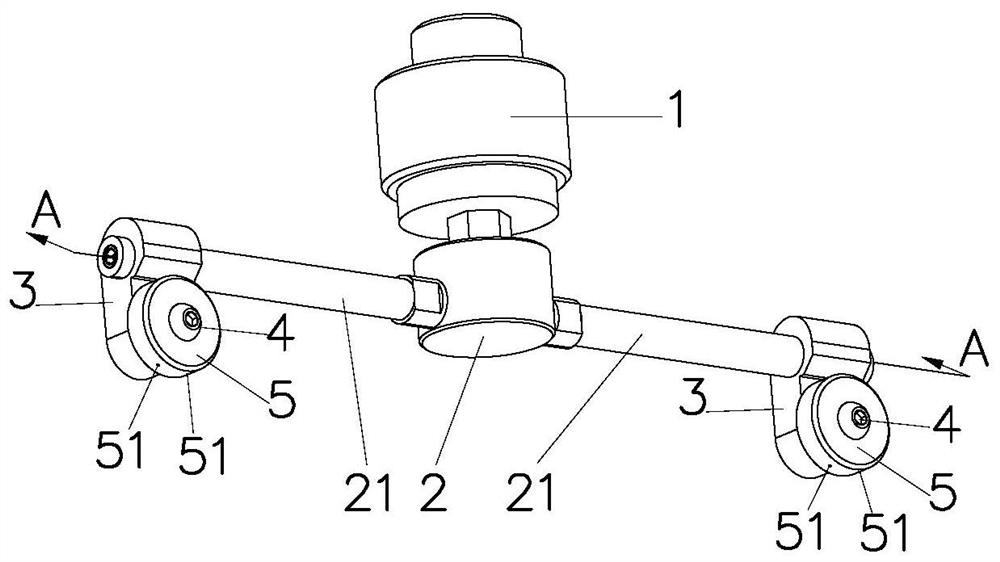

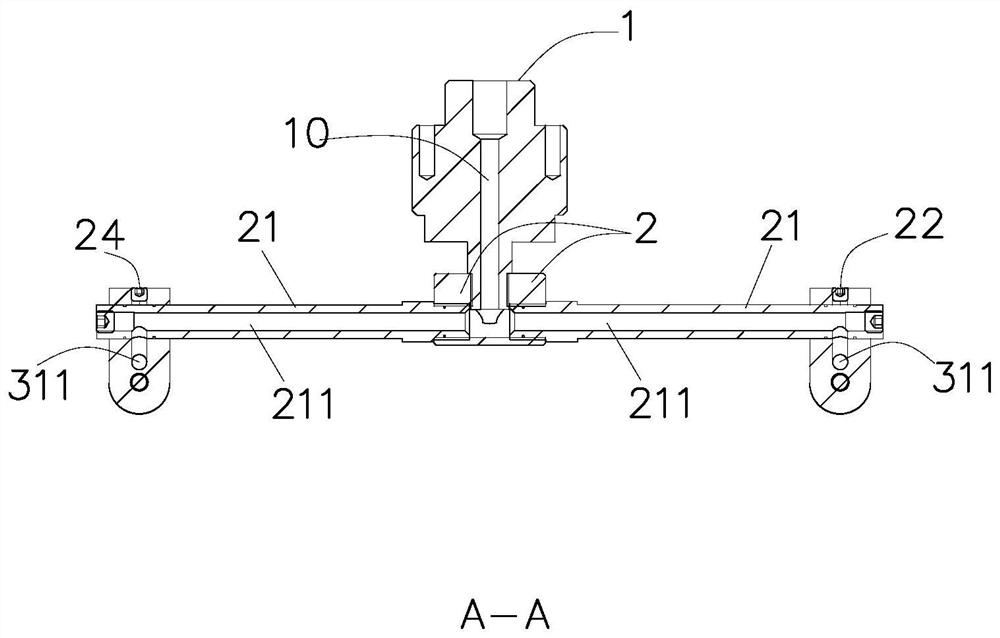

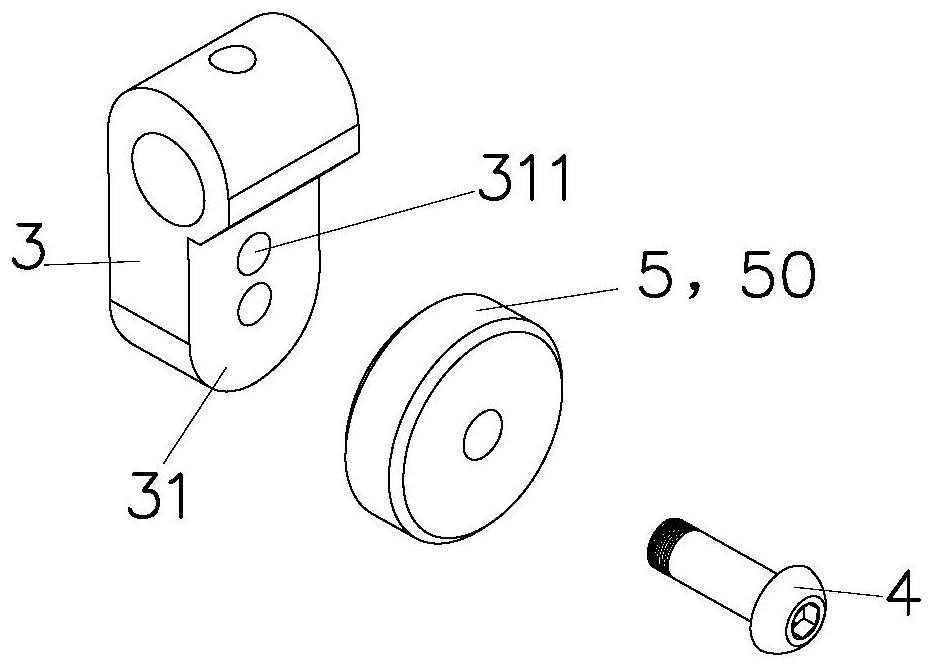

[0021] Such as Figure 1 to Figure 4 As shown, a rotary air outlet device includes a connecting seat 1, the connecting seat 1 is connected with a hollow movable part 2 capable of rotating around a vertical axis, and the connecting seat 1 is provided with a The first channel 10 of the hollow movable part 2 is connected with several horizontal tubes 21 distributed in the circumferential direction, and the second channel 211 communicating with the hollow movable part 2 is arranged in the horizontal tubes 21, so The horizontal tube 21 is provided with a connecting portion 3 communicating with the second channel 211, and the connecting portion 3 communicates with an air outlet head 5 through a communication connection structure that can adjust the air outlet direction and lock the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com