Plate type heat exchanger with sufficient and uniform heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

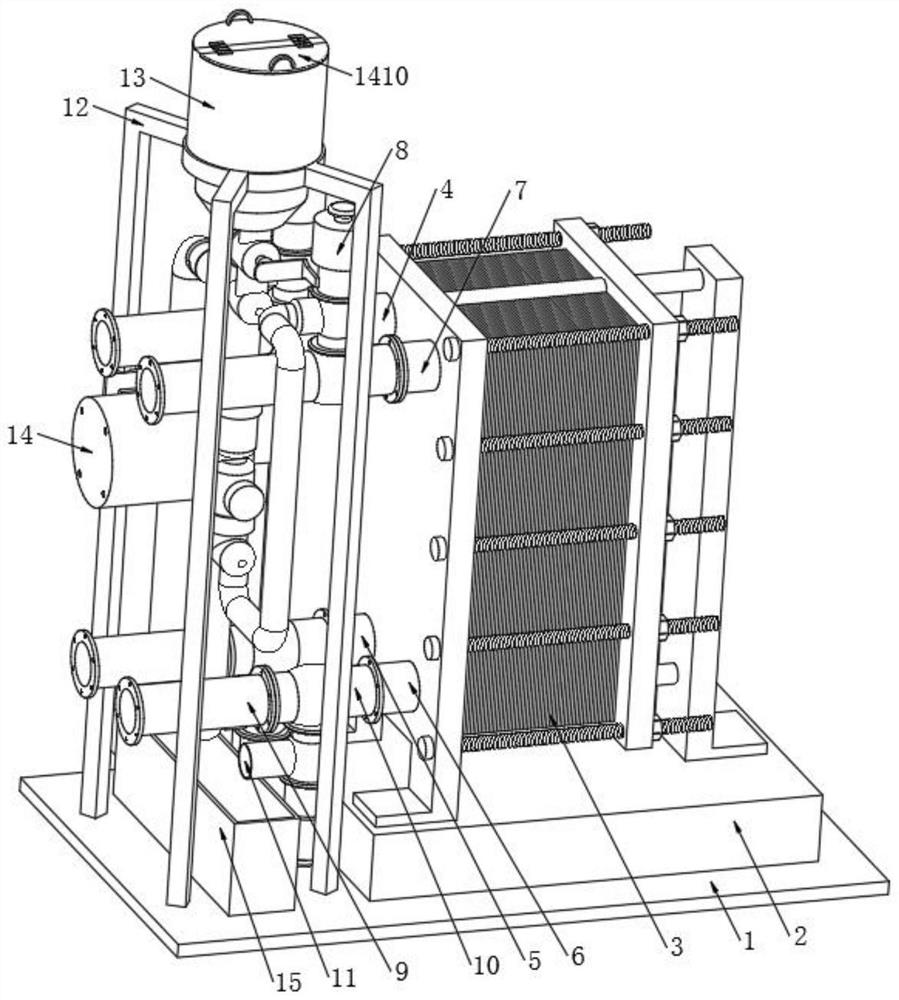

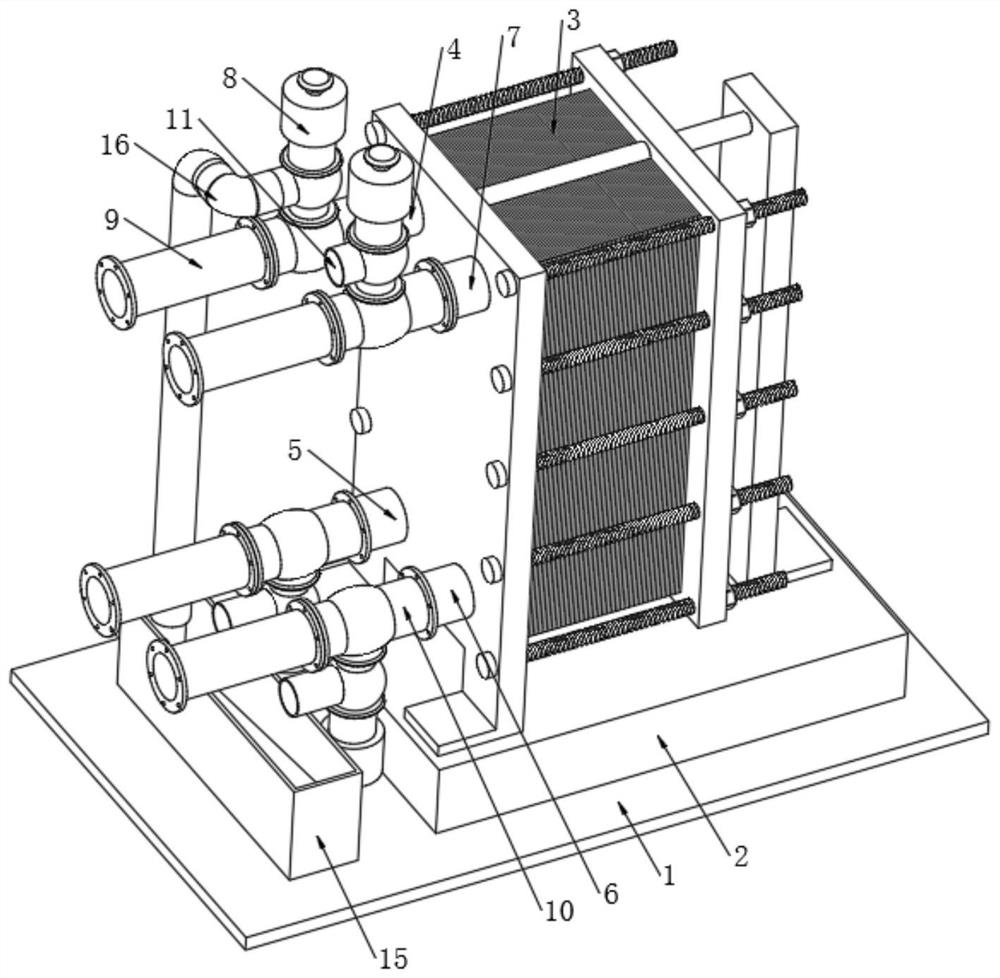

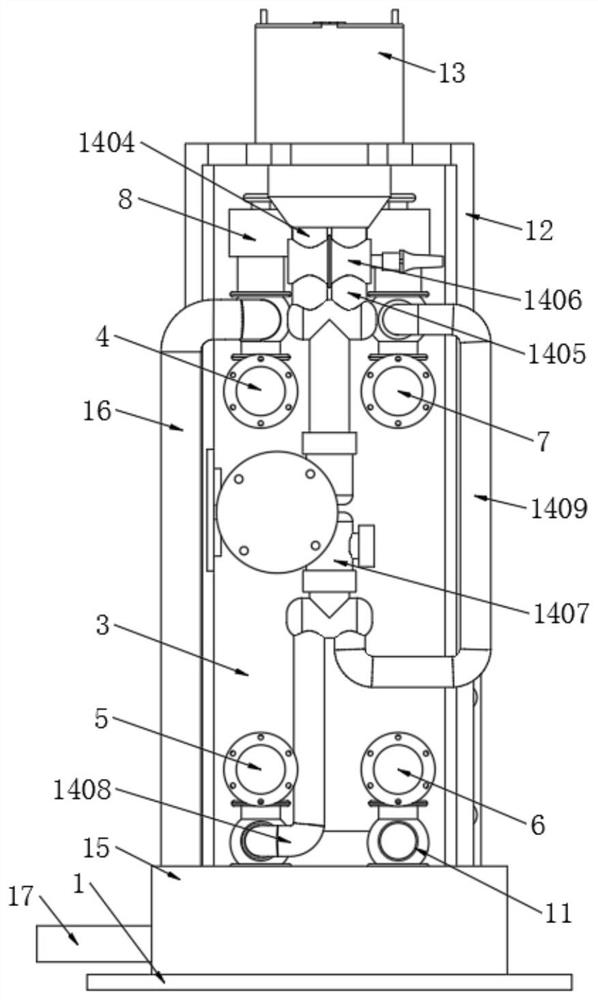

[0024] Such as figure 1 As shown, one heat exchange sufficiently uniform plate heat exchanger proposed by one embodiment of the present invention, including the bottom plate 1, and the top of the bottom plate 1 fixes high stage 2, the top of the high stage 2 is fixedly charged with a heat exchanger body 3, and the heat exchanger On the body 3, there is a first commutation valve 8, which is provided above the heat-out port 4, the cold outlet opening 6, and the cold outlet 7, and the bottom plate 1 are provided, respectively, and the first commutation valve 8 is provided with first. The end pipe 9, the second tube 10, and the third connecting tube 11, the heat inlet 4, the heat outlet 5, the end portions of the cold outlet 7 and the cold outlet 7 respectively correspond to the second connecting tube 10 of the corresponding first-reversing valve 8, respectively. Connecting, the top of the bottom plate 1 fixes a bracket 12, the top portion of the bracket 12 is fixed, and a conveying m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com