Transformer performance test platform with wire combing function

A test platform and transformer technology, applied in the field of transformers, can solve problems such as scattered placement and increased difficulty in combing lines, and achieve the effect of speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

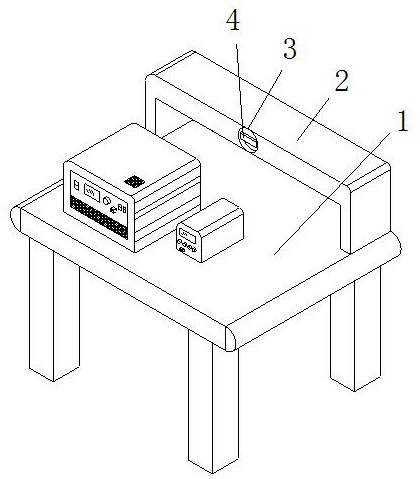

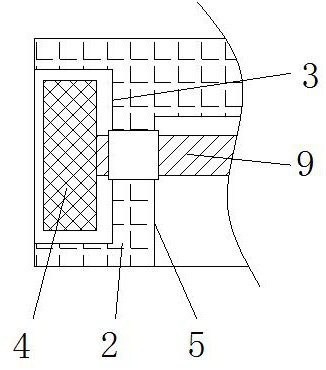

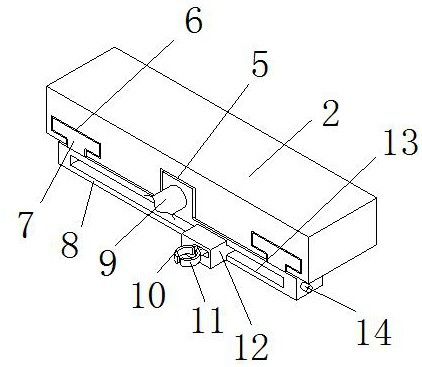

[0023] see Figure 1-3 , the present invention provides a technical solution: a transformer performance testing platform with combing function, including a workbench 1, the top of the workbench 1 can place instruments such as bias DC sources, and the top of the workbench 1 is fixedly connected with a placement rack 2. The placement frame 2 is in the shape of a 匚. The top of the vertical plate of the placement frame 2 can place instruments such as signal generators. The bottom of the vertical plate of the placement frame 2 is provided with a moving groove 5, and the inner wall of the moving groove 5 is rotatably connected with a first threaded rod 9 , the inside of the moving groove 5 is slidably connected with a support plate 8 threaded with the surface of the first threaded rod 9, the support plate 8 is in a reverse T shape, and the bottom of the support plate 8 slides through the inside of the moving groove 5 and extends to the moving groove 5 Outside, the left side of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com