Hot processing method of raw black tea and bean-fragrance black tea

A technology of thermal processing of black hair tea, applied in tea treatment before extraction, etc., can solve the problems of low aroma and light taste of black hair tea, and achieve the effect of solving light taste, low aroma and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

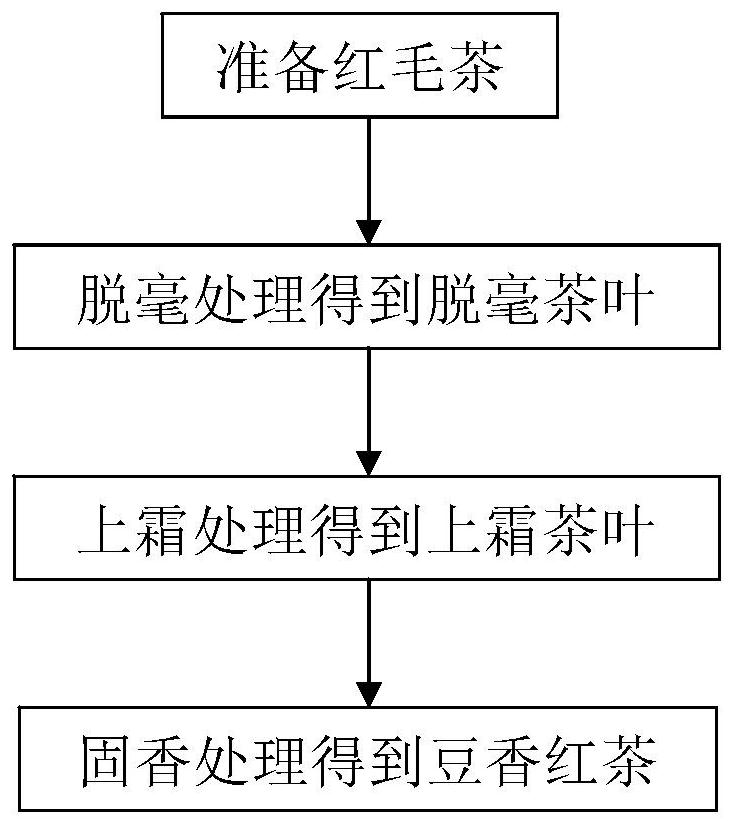

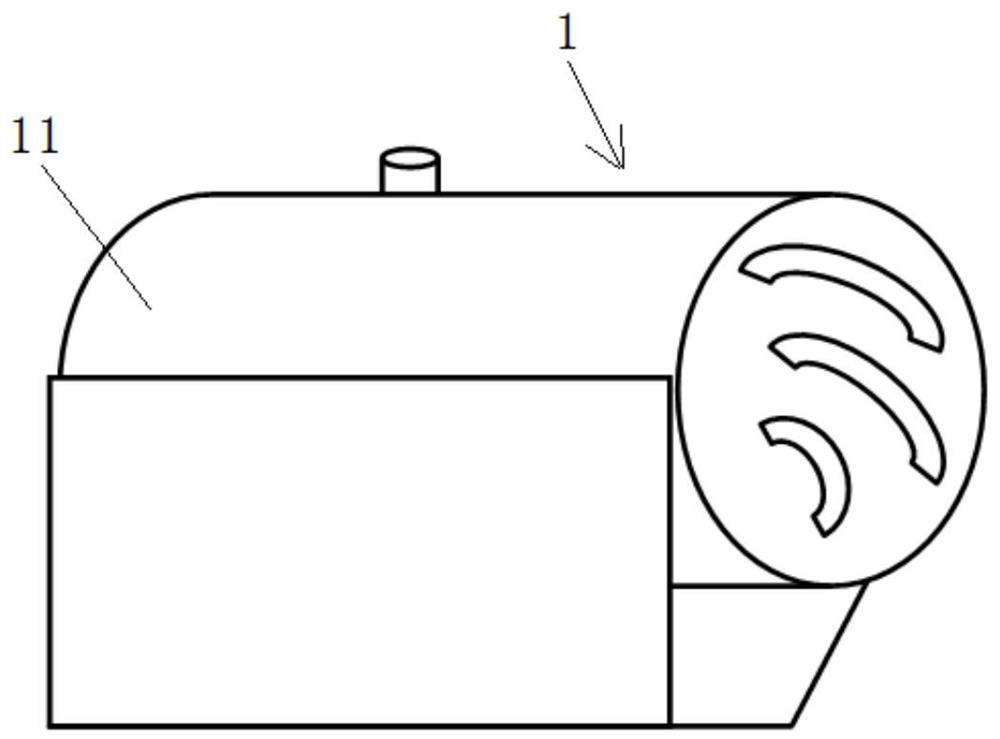

[0025] like figure 1 As shown, the present invention provides a method for thermal processing of black hair tea, which includes the following steps in sequence: depilation, at a first preset temperature, low-grade black hair tea is subjected to depilation treatment to obtain the depilation after depilation. Frosting: Frosting the depigmented tea leaves at the second preset temperature to obtain frosted tea leaves with a dark green color and smooth and shiny surface; solidifying the fragrance: curing the frosted tea leaves at the third preset temperature Fragrant treatment.

[0026] According to the thermal processing method of the black hair tea of the present invention, the low-grade black hair tea is optimized into a bean that tastes mellow and sweet and retains nutritional components by sequentially performing hair removal treatment, frosting treatment and aroma fixing treatment Fragrant black tea solves the problem of low aroma and light taste of black hair tea processe...

Embodiment approach 2

[0041] The present invention also provides a bean-flavored black tea, which is prepared by the above-mentioned thermal processing method of black hair tea. The beneficial effect of the bean-flavored black tea is the same as the beneficial effect of the reprocessing method of the black hair tea in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com