A microwave and far-infrared composite roasting method for improving the quality of new Tieguanyin tea

A technology of composite baking and Tieguanyin, applied in the field of microwave and far-infrared composite baking, to achieve the effects of large-scale standardized production, stable quality, and improved aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

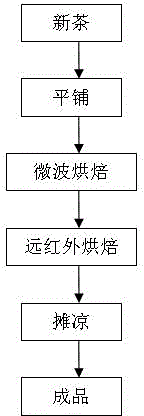

Method used

Image

Examples

Embodiment 1

[0017] A microwave and far-infrared composite baking method for improving the quality of new Tieguanyin tea, the specific steps are as follows:

[0018] 1. Take the new Tieguanyin tea and spread it on a baking tray with a thickness of 2-3cm;

[0019] 2. The tea leaves are baked intermittently by microwave, that is, baked for 5s, paused for 5s, and cycled for 2 hours. The microwave temperature is 60°C and the microwave frequency is 2450MHz;

[0020] 3. After the microwave roasting, the tea leaves are roasted by far infrared, the heating temperature is 100°C, the wavelength is 40 μm, and the roasting time is 1 h;

[0021] 4. Cool the compound-baked tea leaves to room temperature, and then pick, weigh, and pack them into finished products.

Embodiment 2

[0023] A microwave and far-infrared composite baking method for improving the quality of new Tieguanyin tea, the specific steps are as follows:

[0024] 1. Take the new Tieguanyin tea and spread it on a baking tray with a thickness of 2-3cm;

[0025] 2. The tea leaves are baked intermittently by microwave, that is, bake for 5s, pause for 5s, and cycle for 2.5 hours. The microwave temperature is 55°C and the microwave frequency is 2900MHz;

[0026] 3. After the microwave roasting, the tea leaves are roasted by far infrared, the heating temperature is 95°C, the wavelength is 80 μm, and the roasting time is 1.5 h;

[0027] 4. Cool the compound-baked tea leaves to room temperature, and then pick, weigh, and pack them into finished products.

Embodiment 3

[0029] A microwave and far-infrared composite baking method for improving the quality of new Tieguanyin tea, the specific steps are as follows:

[0030] 1. Take the new Tieguanyin tea and spread it on a baking tray with a thickness of 2-3cm;

[0031] 2. The tea leaves are baked intermittently by microwave, that is, bake for 5s, pause for 5s, and cycle for 3 hours. The microwave temperature is 50°C and the microwave frequency is 4000MHz;

[0032] 3. After the microwave roasting, the tea leaves are roasted by far infrared, the heating temperature is 90°C, the wavelength is 100 μm, and the roasting time is 2 h;

[0033] 4. Cool the compound-baked tea leaves to room temperature, and then pick, weigh, and pack them into finished products.

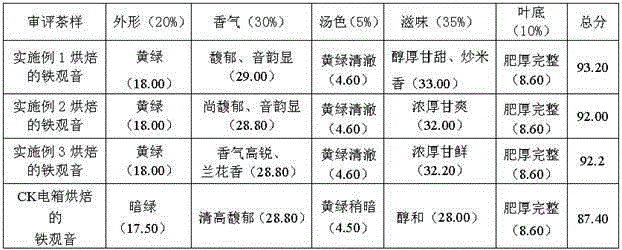

[0034] According to GB / T23776-2009 "Tea Sensory Evaluation Method": the sensory quality indicators of the Tieguanyin tea leaves baked by the production process of the embodiment of the present invention and the Tieguanyin baked by the tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com