Automatic sorting device for logistics goods

An automatic sorting and cargo technology, applied in sorting, transportation and packaging, conveyors, etc., can solve the problems of low practicability, poor adaptability, and inability to realize transmission, so as to improve flexibility, stable use, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Example: Please refer to Figure 1 to Figure 11 :

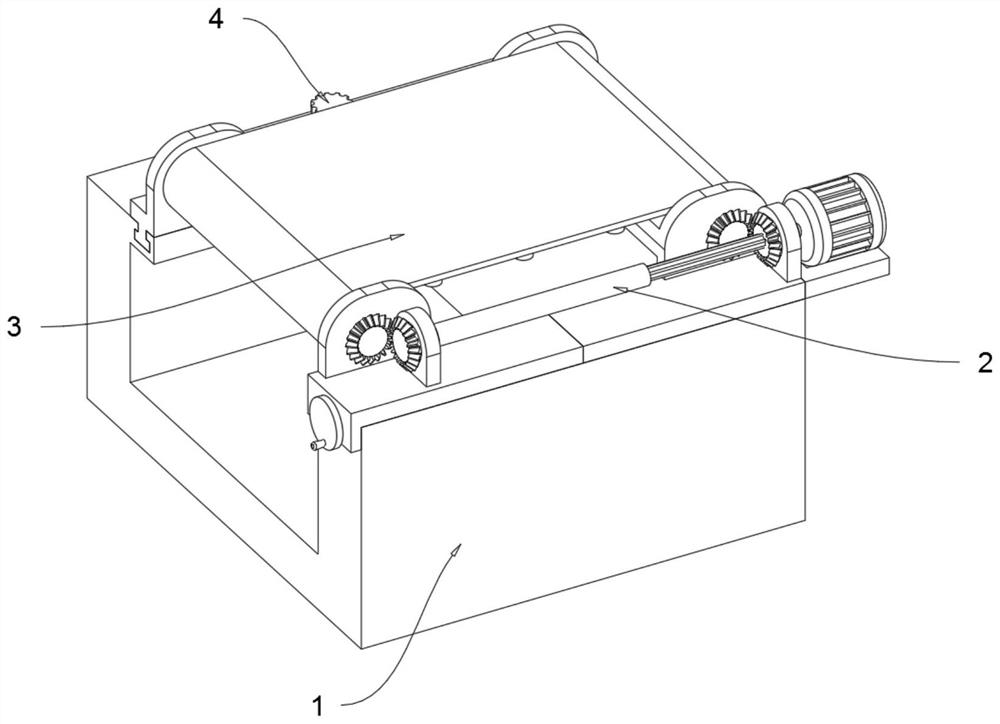

[0045] The present invention proposes an automatic sorting device for logistics goods, including an installation base 1;

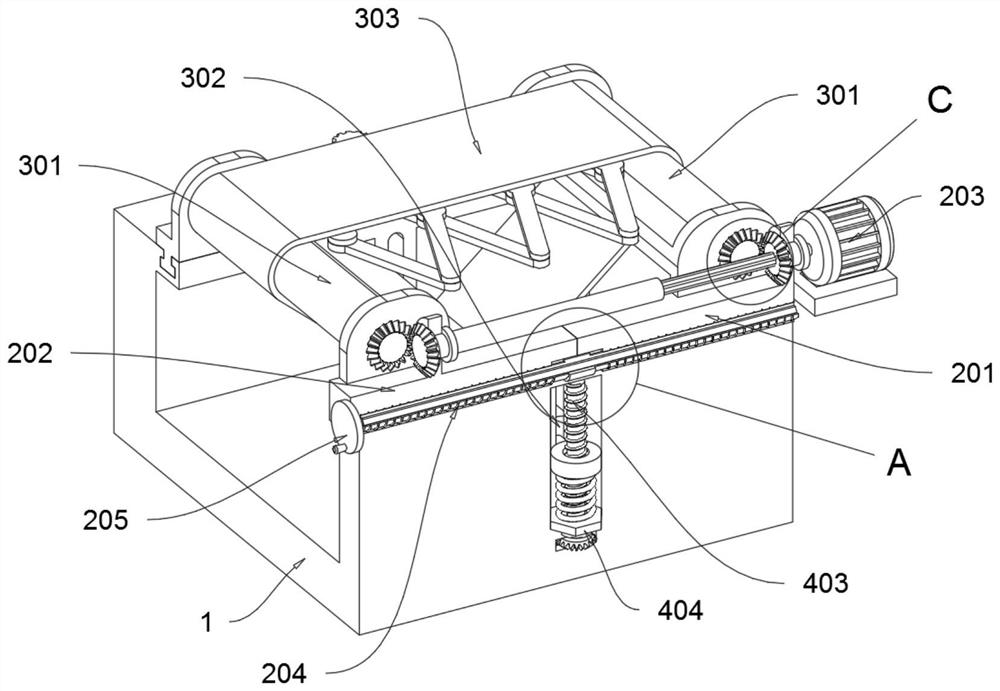

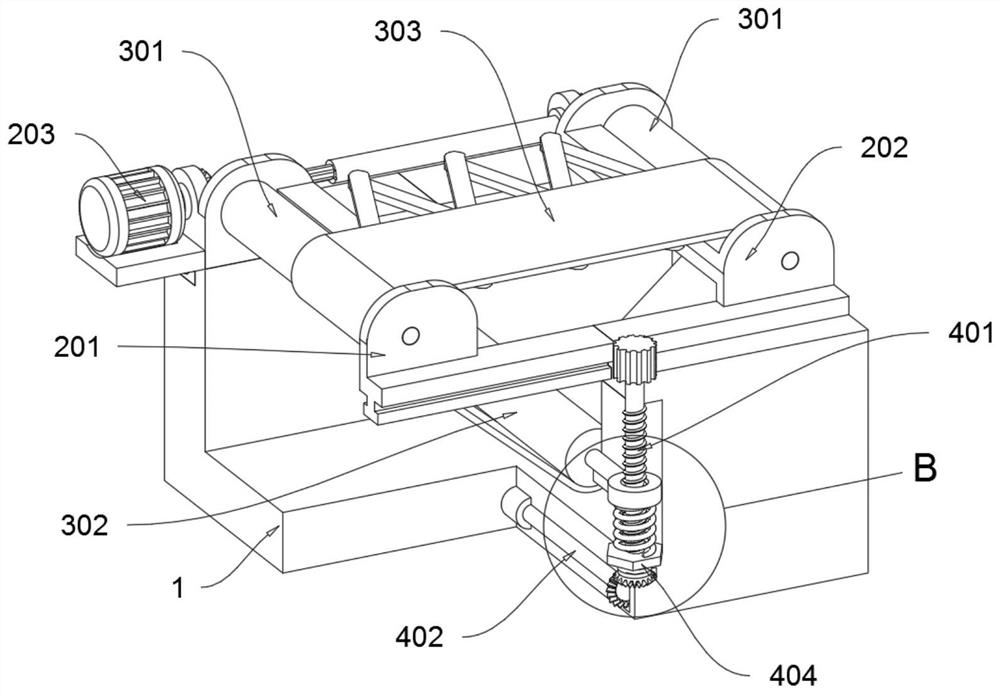

[0046] The interior of the installation base 1 is equipped with a control assembly, which includes a drive mechanism 2, a transmission mechanism 3 and a tension mechanism 4;

[0047]The drive mechanism 2 includes a drive base 201, a follower base 202 and a drive motor 203, the drive base 201 is inserted on the top of the installation base 1, and the follower base 202 is inserted on the top of the installation base 1, and the drive motor 203 is fixedly installed on the top of the installation base 1. On the side of the driving seat 201, the driving distance of the driving mechanism 2 can be adjusted freely, and the driving mechanism 2 can drive the transmission mechanism 3 to change the transmission length when adjusting the driving distance;

[0048] The drive motor 203 is electrically connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com