A municipal snow removal device

A municipal and snow tube technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve problems such as high failure rate, lack of reliability, and inability to accurately blow objects of different sizes, achieving good reliability and low failure rate low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

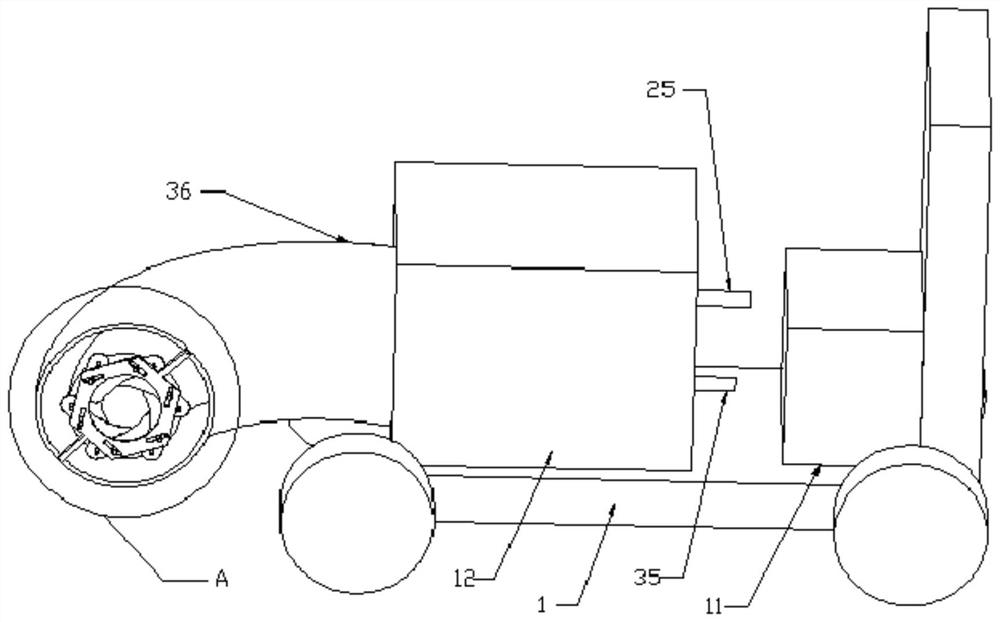

[0034] combine Figure 1 to Figure 8 As shown in the figure, a municipal snow removal device adopts a jet snow blower 1, and the jet snow blower 1 includes an operator seat 11, a protection box 12 and a snow blowing pipe 13, and the protection box 12 and the operator seat 11 are arranged in sequence in On the jet snow blower 1 , the blowing box 14 is arranged in the protection box 12 , the air inlet 133 of the snow blowing pipe 13 is connected with the blowing box 14 , and a blower is provided at the connecting place, and the air outlet of the snow blowing pipe 13 extends out of the protection box 12 . In addition, it also includes an angle adjustment mechanism 2 and an opening adjustment mechanism 3; the air outlet of the snow blowing pipe 13 is provided with an opening adjustment mechanism 3 for the operator to manually adjust the size of the air outlet opening 134. It can be manually adjusted on the operator's seat 11, which is convenient to operate; the snow blower 13 is r...

Embodiment 2

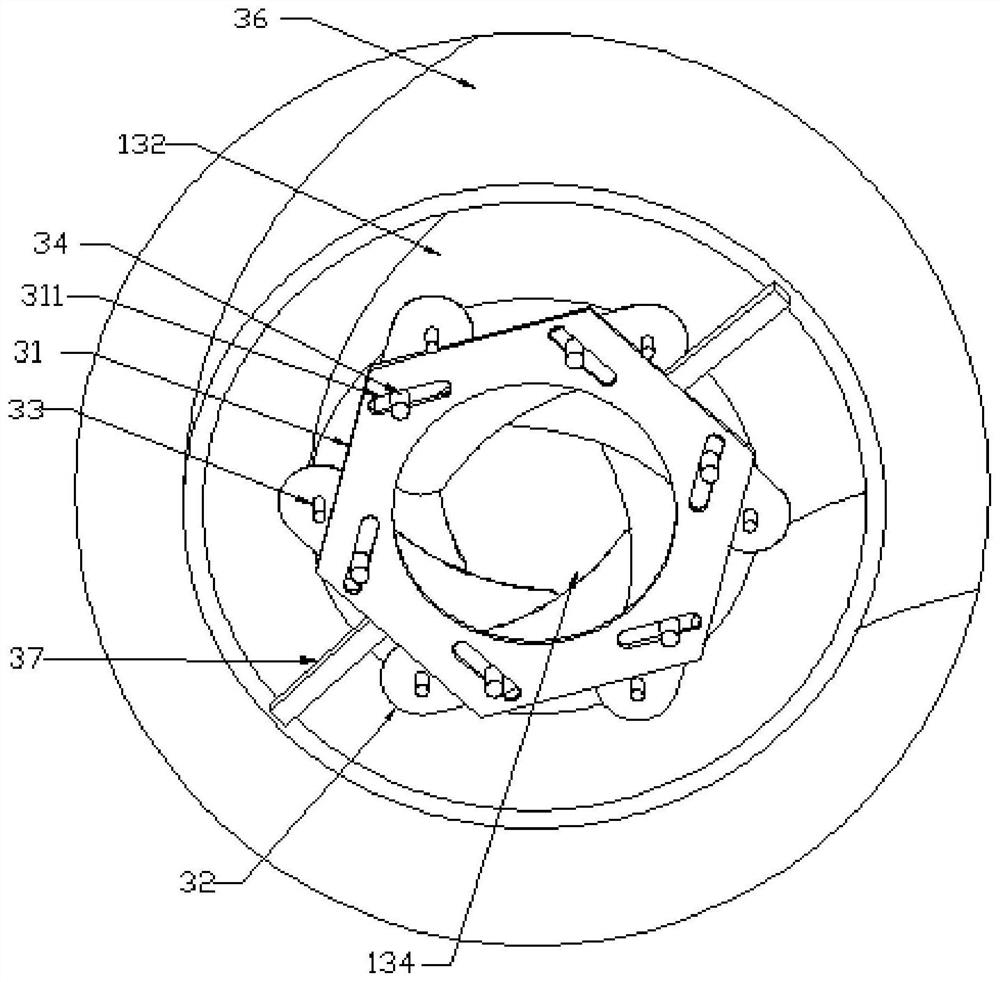

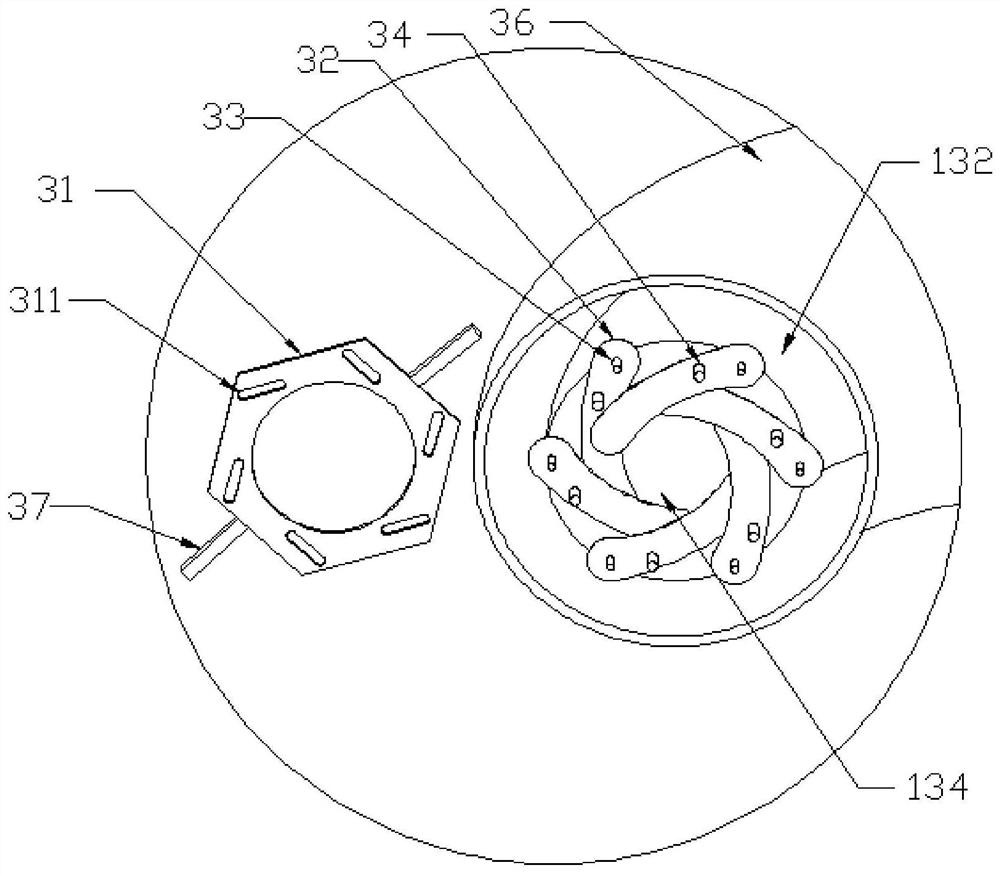

[0036] On the basis of Example 1, as Figure 1-Figure 3 , the opening adjustment mechanism 3 includes an adjustment member and a plurality of wind shields 32; one end of each wind shield 32 is hinged on the end face of the air outlet hole of the snow blowing pipe 13 through a corresponding connecting shaft 33; each wind shield 32 is evenly distributed along the air outlet distributed and stacked in sequence;

[0037] The adjusting pieces are arranged on the outside of each wind shield 32; each wind shield 32 can rotate synchronously around the corresponding connecting shaft 33 under the driving of the adjusting piece, thereby changing the opening formed by each wind shield 32 and the air outlet hole of the snow blowing pipe 13 134 size.

[0038] The opening adjustment mechanism 3 also includes a positioning column 34; the adjustment member adopts a turret 31; The positioning column 34 is adapted to the guide through groove 311; each wind shield 32 is provided with a position...

Embodiment 3

[0042] On the basis of Example 1, as Figure 4-Figure 8 , the angle adjustment mechanism 2 includes an adjusting cylinder 22 and a flat-bottomed screw 23; the snow blowing pipe 13 is composed of a straight cylinder 131 and a curved cylinder 132; 14 are connected in rotation, and one end of the bending cylinder 132 (the air outlet of the snow blowing pipe 13) protrudes out of the protective box 12;

[0043] The adjusting cylinder 22 is rotatably coaxially sleeved on the outer peripheral side of the straight cylinder 131, and the inner wall of the adjusting cylinder 22 is in conflict with the outer wall of the straight cylinder 131; The outer side wall of the straight cylinder 131 is provided with an arc-shaped through groove II 1311 which is adapted to the lower end of the flat-bottomed screw 23; The oblique line of the through groove II 1311 on the outer side wall of the straight cylinder 131 developed along the bus bar is relative to the inclination of the acute angle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com