Auxiliary manufacturing device for new material coating agent of physiotherapy tent

A technology for making devices and new materials, applied in mixers with rotary stirring devices, transportation and packaging, chemical/physical processes, etc., can solve problems such as reduced efficiency, toxic gas damage to the body, and cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

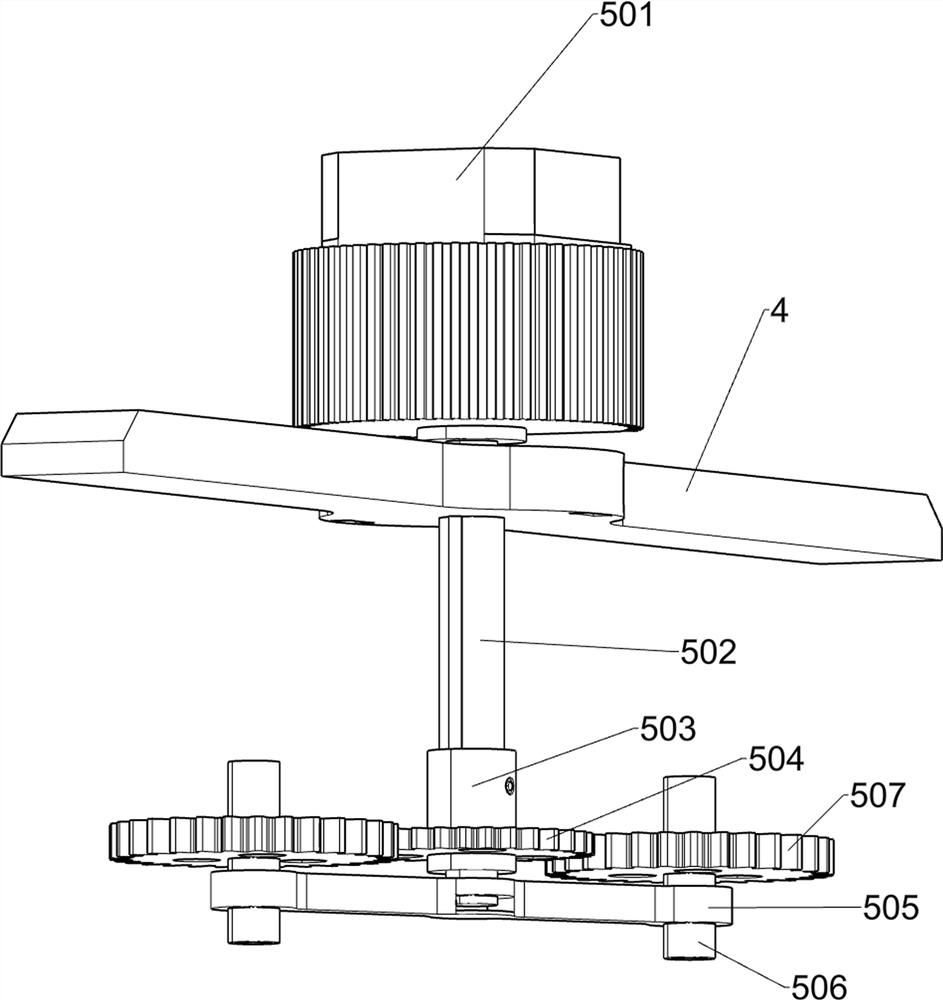

[0027] One kind of new materials, tent coating agent therapy auxiliary production devices, such as Figure 1-3 Shown, comprises a bottom plate 1, the first support frame 2, placing plate 3, lever 4 days, the drive mechanism 5 and the mixing means 6, before and after the base plate 1 on both sides are connected to first support 2, the lower portion of the first bracket 2 placing plate 3 is provided between the first support frame 2 is connected between an upper portion of the rod 4 days, 5 days rod is provided with a drive mechanism 4, the drive mechanism is connected between the plate 53 and the mixing means 6 is placed.

[0028] Drive mechanism 5 includes a servo motor 501, the positioning sleeve 502, a first sleeve 503, a first gear 504, the connecting plate 505, a first fixed shaft 506 and the second gear 507, the lever 4 days servomotor 501 is provided intermediate the top , the intermediate bottom 4 and an output shaft of the servo motor 501 is rotated connection rod 4 days, d...

Embodiment 2

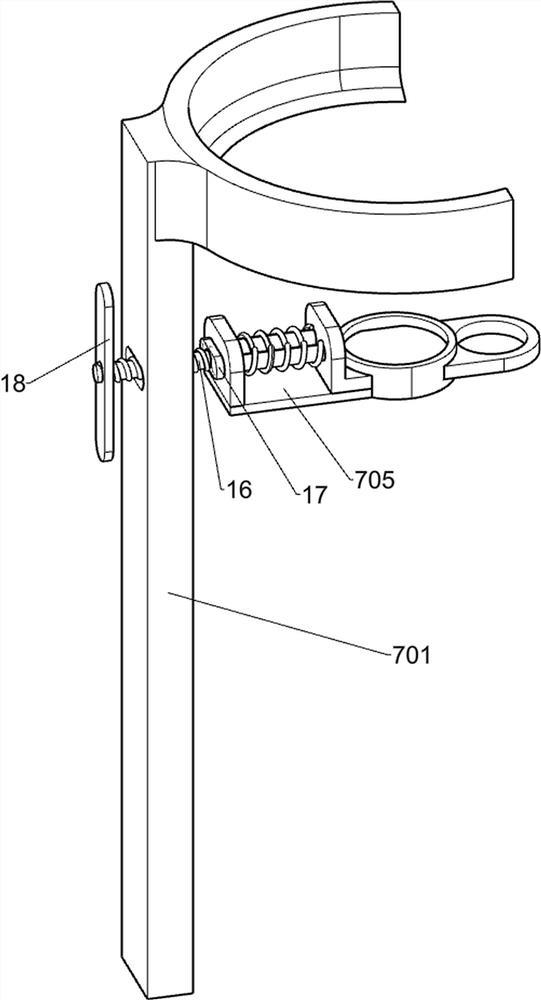

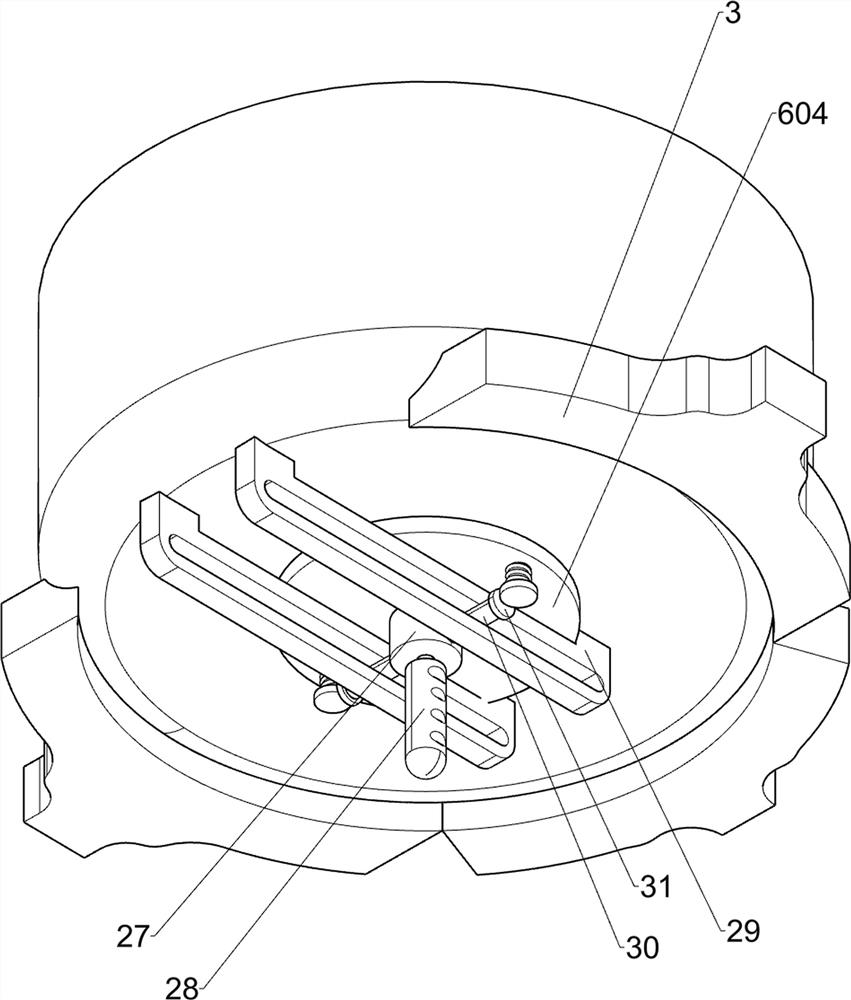

[0032] On the basis of Example 1, such as Figure 4-8Shown, further comprising cutting means 7, the feeding mechanism 7 includes a second support frame 701, the feed tank 702, the cover plate 703, connecting ring 704, L-type block 705, slide block 706, a first guide bar 707, The first spring 708 and the toggle lever 709, the top plate 3 is placed on the left side is provided with second support 701, second support 701 is provided with an upper feed tank 702 feed tank 702 has a top cover plate 703, the lower portion of the material tank 702 connecting ring 704 is provided, connecting ring 704 and slidably connected to feed tank 706 between the slider 702, the lower left feed tank 702 is provided with an L-shaped block 705, 707 is provided with two first guide bar 706 on the slider, The first guide rod 707 and the L-shaped block 705 slidably connected to the sliding block 706 is connected between the both sides of the left portion 705 and a first L-shaped spring block 708, the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com