Construction method of bored pile main body steel casing under deepwater foundation and bare rock environment

A deep-water foundation and construction method technology, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of insufficient rigidity of steel casing, heavy steel casing, and inability of steel casing to stabilize itself. Solid problem, convenient and fast rock entry, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with implementation examples and with reference to the accompanying drawings.

[0025] A construction method for the steel casing of the main body of the bored pile under the environment of deep water foundation and bare rock, the construction steps are as follows:

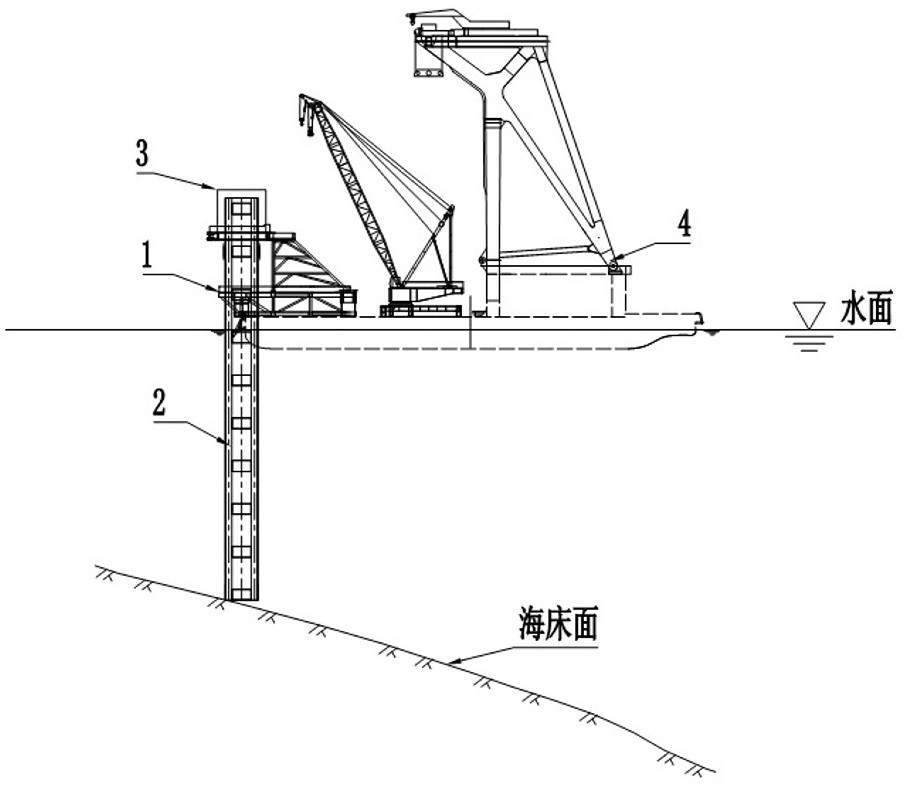

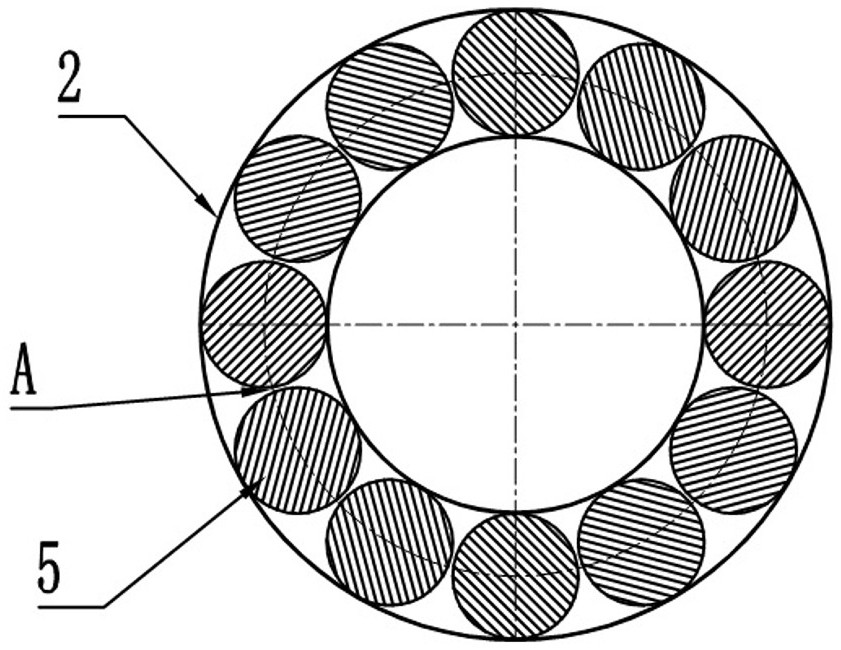

[0026] (1) Positioning of the piling ship 4 and lowering of the auxiliary steel casing 2: set the guide platform 1 for fixing the auxiliary steel casing 2 on the piling ship 4, drive to the designed pile position and drop anchor for positioning, and use a floating crane to lift the auxiliary steel casing 2. Lower it from the guide platform 1 to the surface of the seabed (the guide platform 1 is provided with upper and lower layers of horizontal constraints to ensure that the auxiliary steel casing 2 resists wave and current loads);

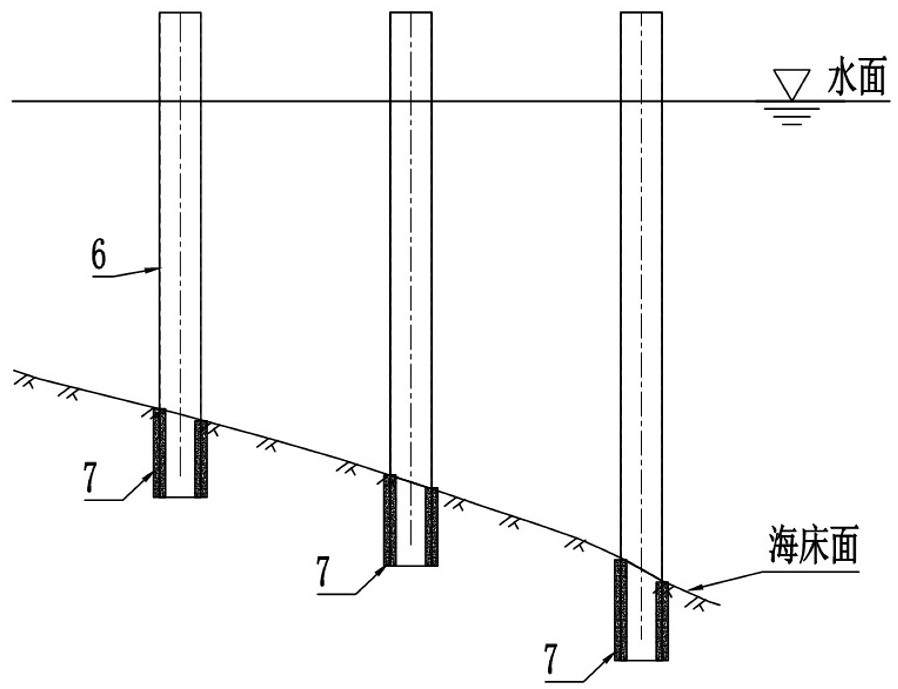

[0027] (2) Preliminary pile stabilization: use a hydraulic impact hammer to lightly hit with a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com