Construction method for pre-burying inter-pile plate steel bars of side slope

A construction method and technology of inter-pile slabs, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as hidden quality problems, inconvenience in planting reinforcement, and inability to ensure the stability and safety of slopes, so as to ensure construction quality and good quality. Effects on Economic and Social Value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

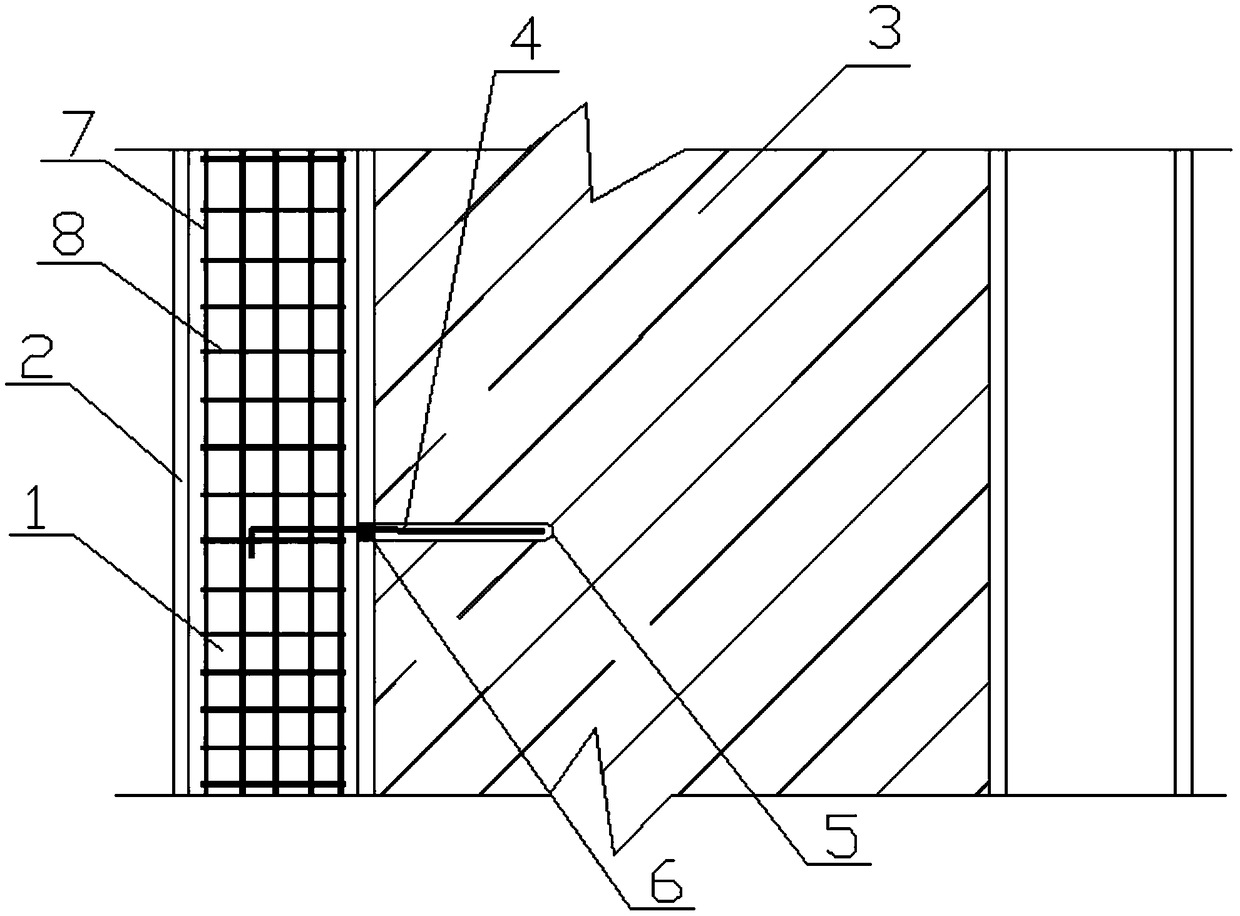

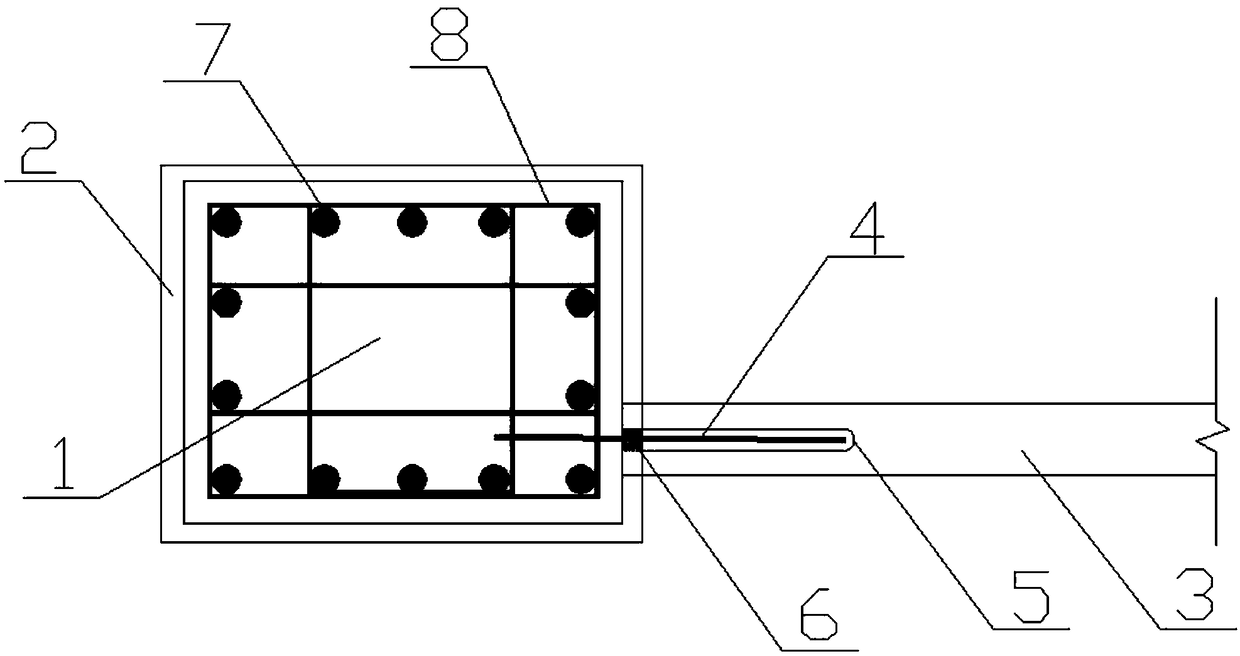

[0026] Such as Figure 1-2 Shown: .

[0027] A method for pre-embedding steel bars between piles on a side slope, comprising the following steps:

[0028] Step 1: On the anti-slide pile guard arm 2 in which the anti-slide pile 1 has been formed, a drill hole 5 is horizontally drilled according to the position of the reinforcement of the inter-pile plate 3;

[0029] Step 2: Install the main reinforcement 7 and stirrup 8 of the anti-slide pile;

[0030] Step 3: Place the pre-embedded reinforcement 4;

[0031] Step 4: Use mortar 6 to seal and compact the pre-embedded steel bar 4 at the anti-slide pile guard arm 2;

[0032] Step 5: pouring pile body concrete.

[0033] In step 1, the depth of the drilled hole 5 is determined according to the overlapping length of the steel bar, and the drilled hole is cleaned up.

[0034] The embedding section of pre-embedded steel bar 4 in Step 3 should meet the anchoring requirements.

[0035] The pre-embedded depth of the pre-embedded stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com