Compressor and air conditioner

A compressor and rotor technology, applied in the field of compressors, can solve the problems of high cost and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

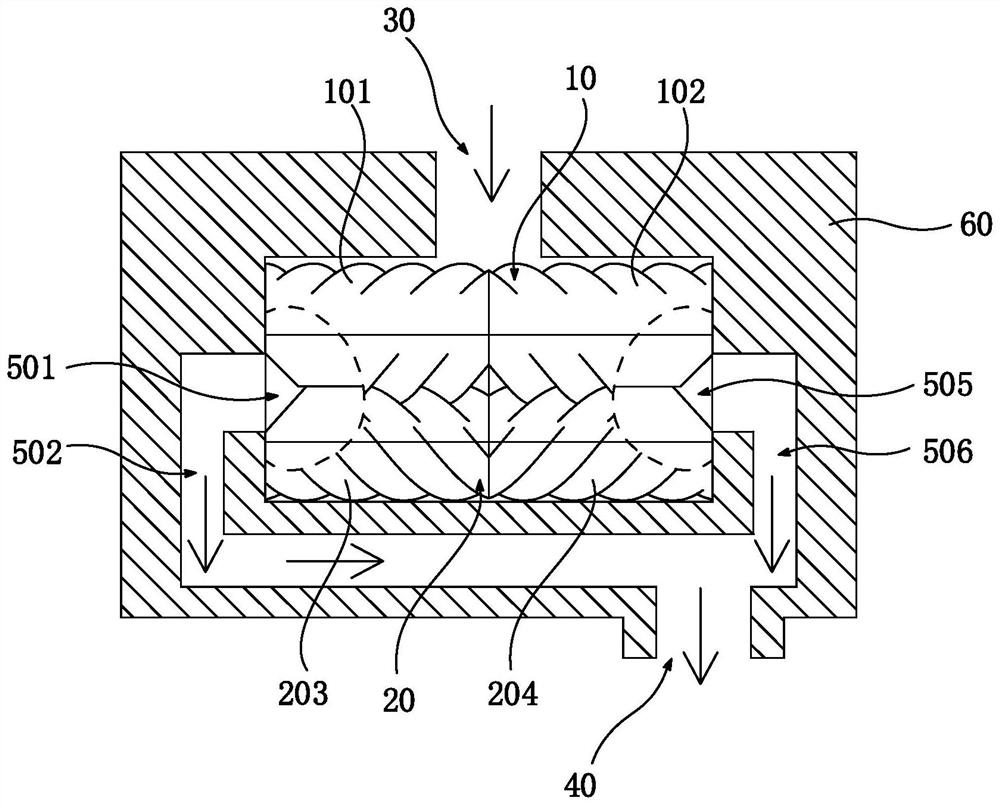

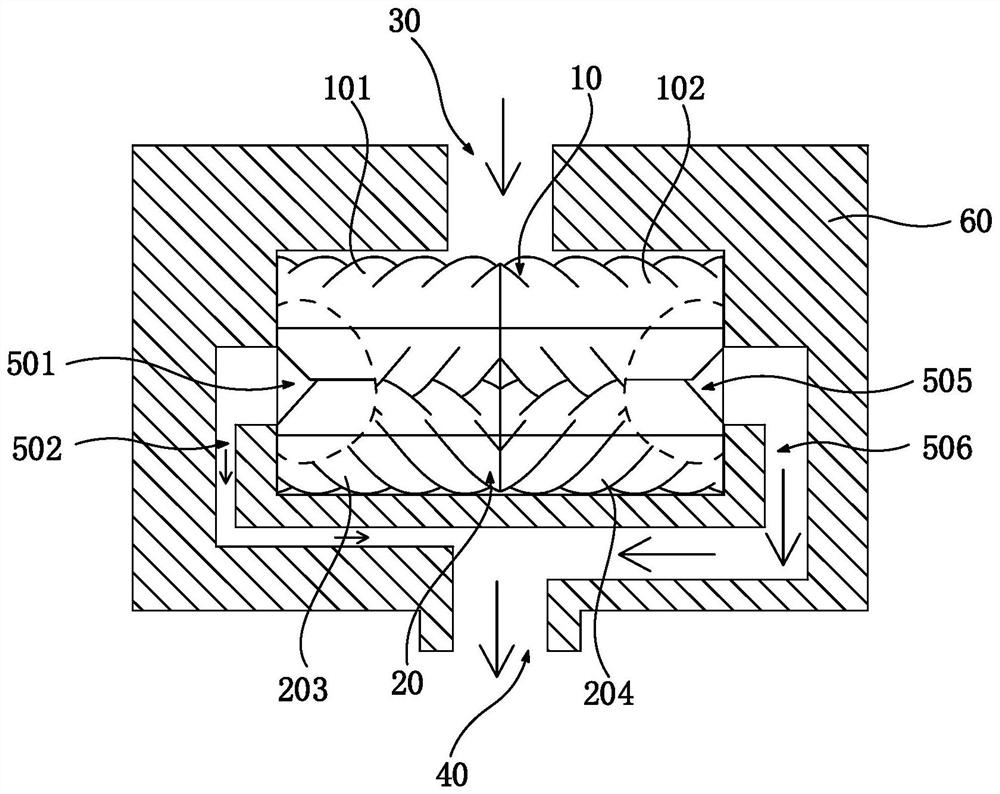

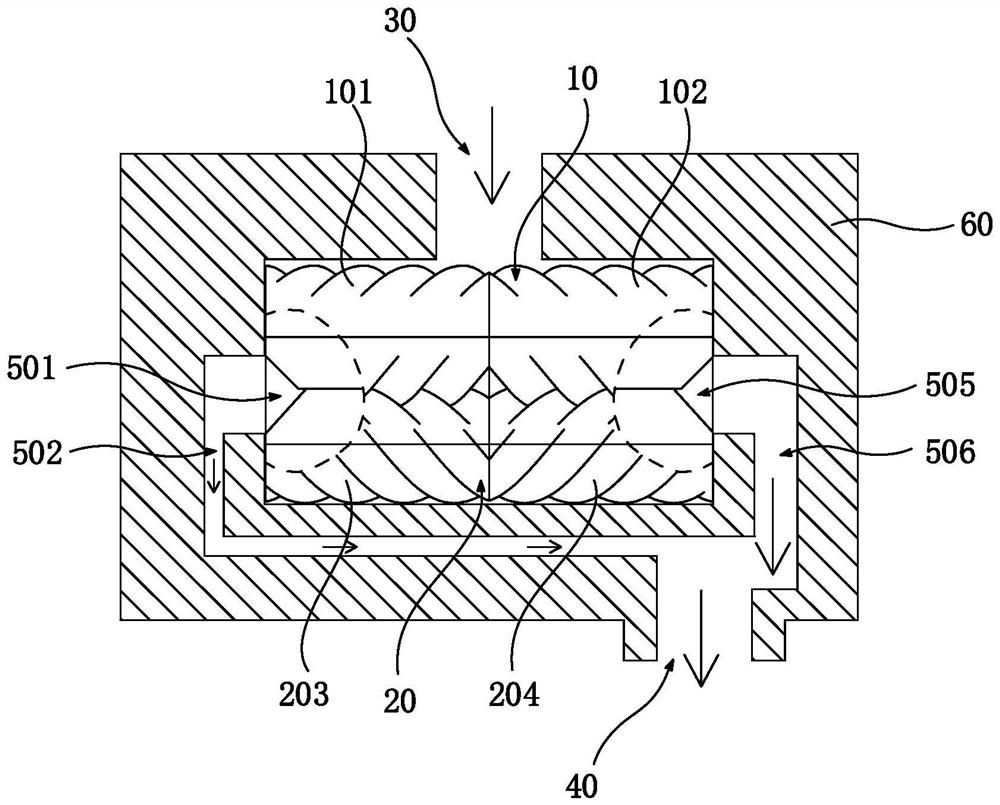

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. The following description of at least one exemplary embodiment is only illustrative in fact, and is never used as any limitation to the present invention and its application or use. Based on the embodiments in the present invention, those skilled in the art do not pay creative work All other obtained embodiments belong to the protection scope of the present invention.

[0034] Reference herein to "an embodiment" or an "implementation" means that a particular feature, structure or characteristic described in connection with the embodiment or implementation can be included in at least one embodiment of the present invention. The occurrences of this phrase in vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com