Bearing oil supply sleeve and bearing oil supply device

A bearing oil supply and sleeve technology, which is applied to bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of difficulty in entering lubricating oil, difficult to meet the lubrication requirements of bearings with high DN value, and increase power loss. Lubricating oil consumption and power loss, improving lubricating cooling effect, improving lubricating and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

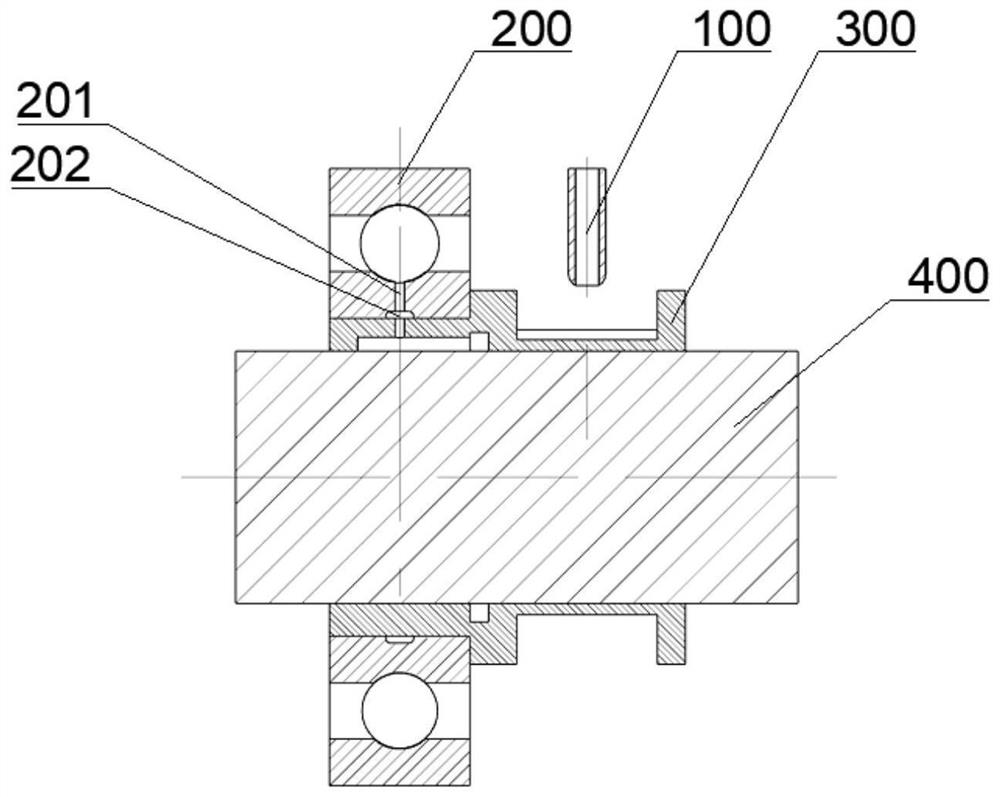

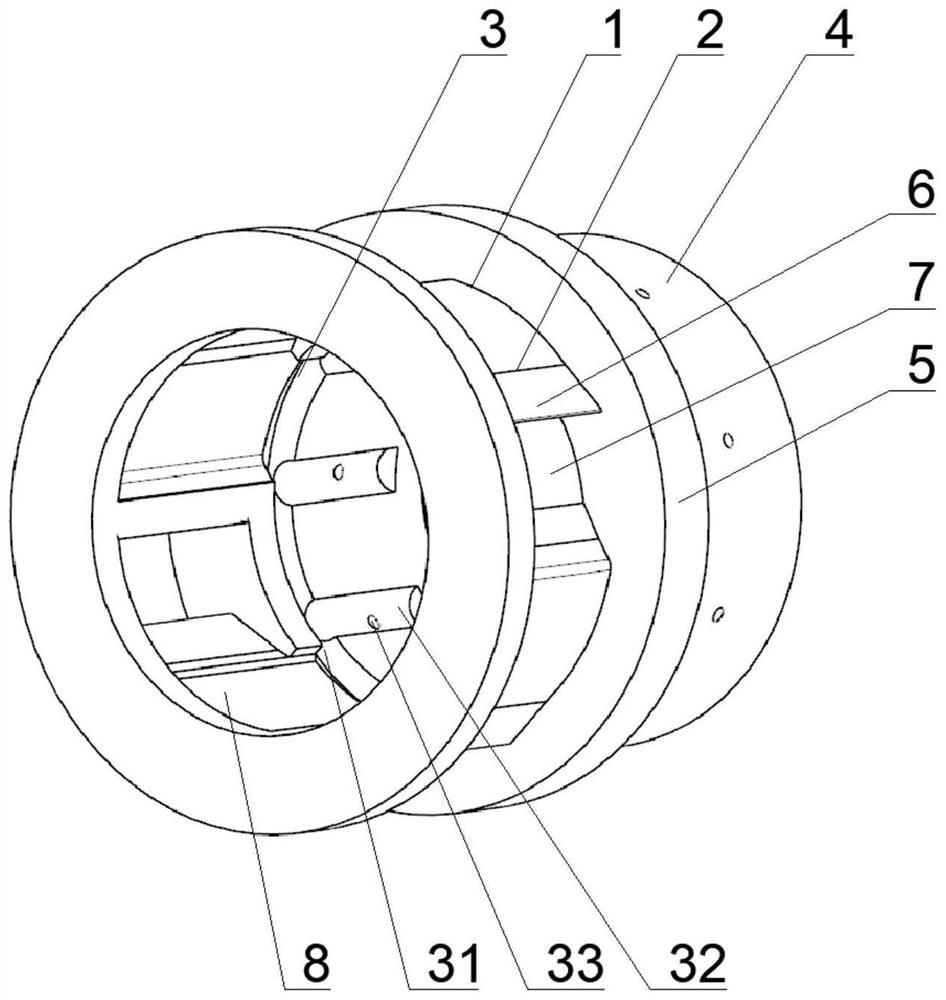

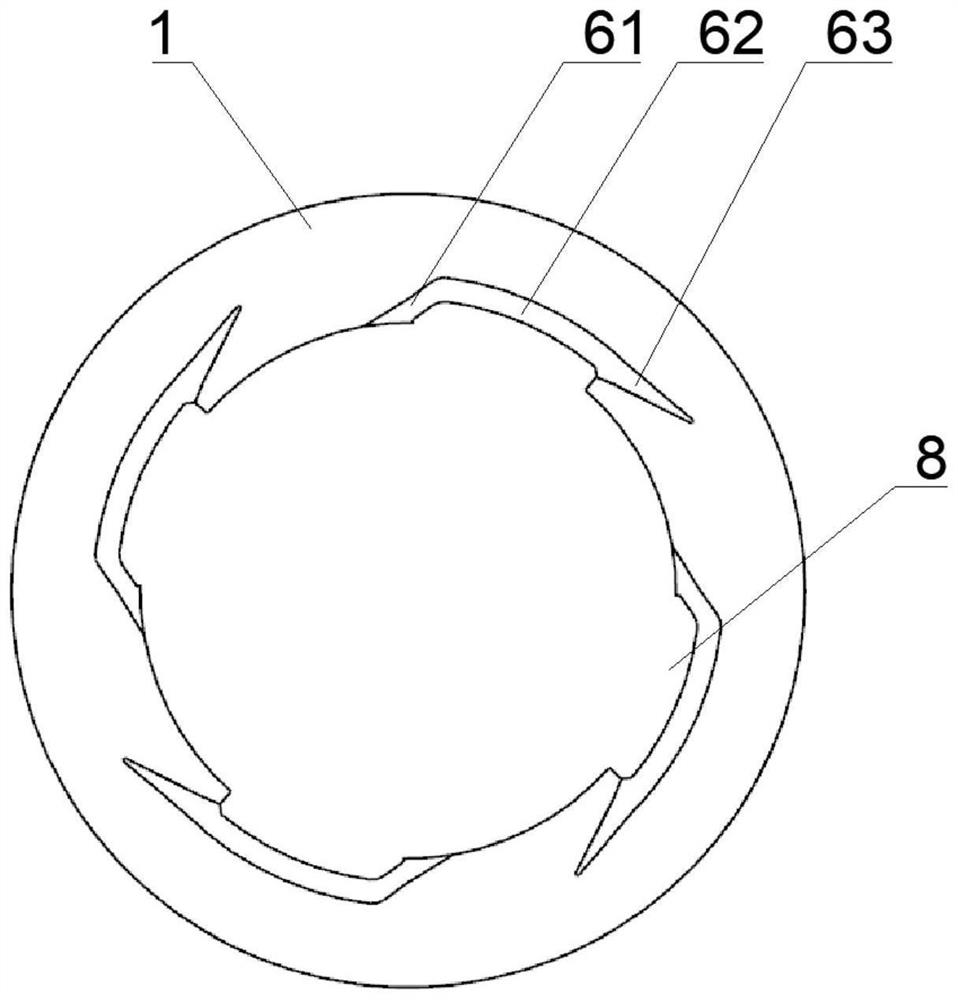

[0031] Such as figure 1 , figure 2 As shown, the present disclosure provides a bearing oil supply bushing 300, including a bushing 1, the inner cavity of the bushing 1 can be installed with a rotating shaft 400, and the outer ring of the bushing is used to install the inner ring of the bearing 200, and the rotating shaft 400 can drive the sleeve when rotating. The tube 1 rotates, and the casing 1 is provided with an oil collecting part 2, a flow distribution part 3 and a bearing mounting part 4:

[0032] Wherein, the oil collecting part 2 is arranged on the outer wall of the casing 1, and is used to collect the oil at the position of the oil collecting part 2; The oil part 2 is pumped into the flow distribution part 3 in the inner cavity of the casing A;

[0033] Wherein, the bearing installation part 4 is arranged on the outer wall of the sleeve 1, and is used for installing the inner ring of the bearing 200; the bearing installation part 4 is a cylindrical structure or a ...

Embodiment 2

[0044] refer to figure 1 , Figure 4 As shown, a bearing oil supply device includes a nozzle 100, a bearing 200 and the above-mentioned bearing oil supply sleeve 300, the nozzle of the nozzle 100 faces the oil collector 2, and the bearing 200 is installed on the bearing installation part 4, and the inner ring of the bearing 200 is also provided with a plurality of oil supply holes 201, one end of the oil supply hole 201 communicates with the distribution part 3, and the other end of the oil supply hole 201 communicates with the The outer ring surface of the inner ring of the bearing 200 communicates. The diameter of the oil supply hole 201 can be exemplarily set between 0.5 mm and 1 mm. The number of oil supply holes 201 can be set between 6 and 24. Other sizes or other quantities can also be set as desired.

[0045] In another embodiment, the inner ring of the inner ring of the bearing 200 is further provided with a bearing oil sump 202 , and the flow distribution part 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Body thickness | aaaaa | aaaaa |

| Circumferential width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com