Anhydrous mechanical seal with self-circulation function

A mechanical seal device and function technology, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems of short life, poor lubrication of anhydrous mechanical seal, heat generation, etc., to prolong the life, strengthen the flow, and solve the complex structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

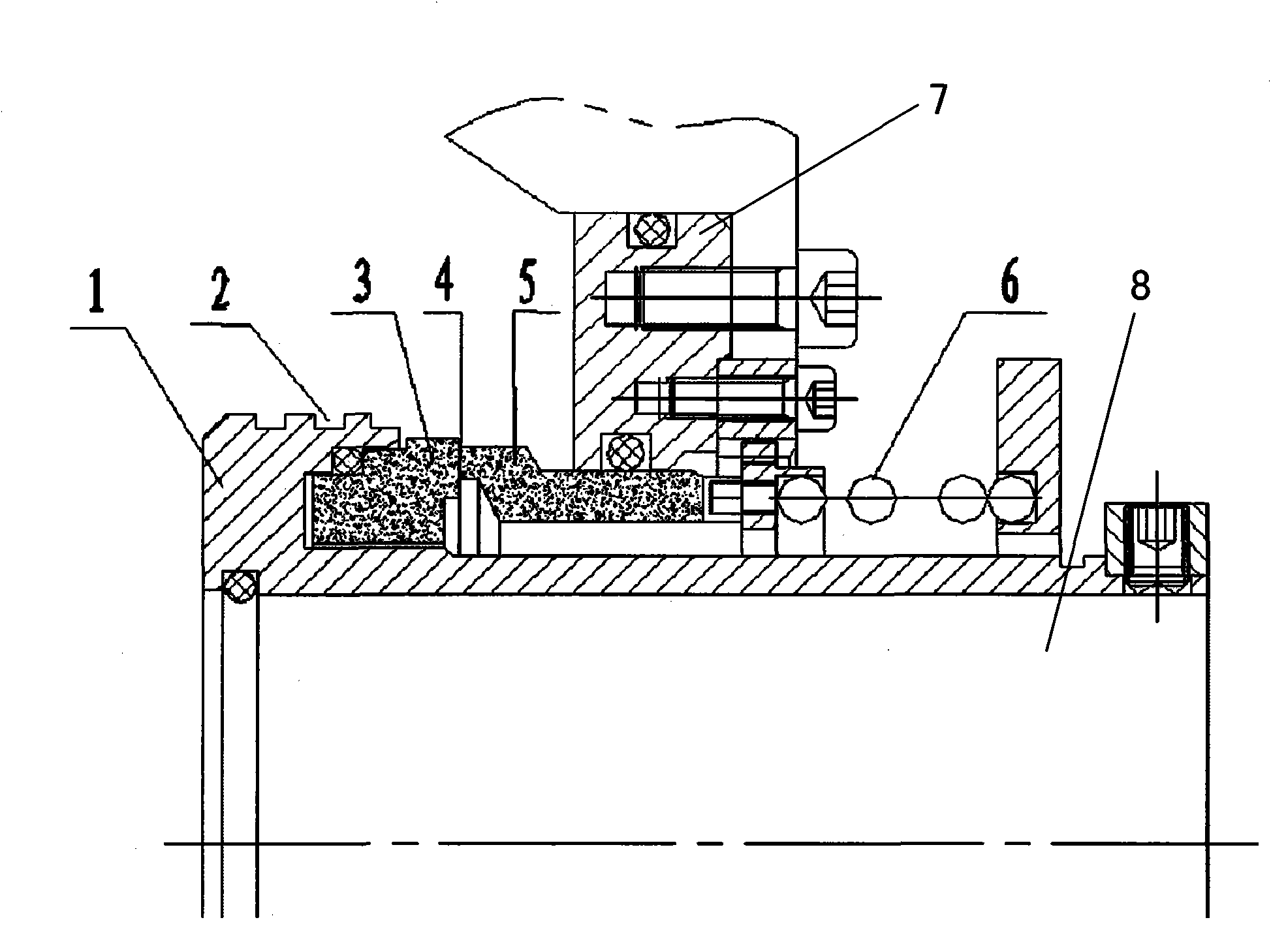

[0012] like figure 1 shown. The sealing device is a single-end structure, does not require external cooling water, and has a self-circulation function, that is, a waterless mechanical seal with a self-circulation function.

[0013] The mechanical seal is composed of a moving ring assembly 1 and a static ring assembly 7 . The moving ring assembly 1 is a rotating ring assembly with a ring-sleeve structure fixed to the rotating shaft 8. The helical groove 2 is arranged on its outer cylindrical surface and is located in the sealing cavity. The inner cavity of the ring sleeve is filled with and fixed silicon carbide material The rotating ring 3; the static ring assembly 6 is fixed with the end cover of the sealing cavity, and the static ring 5 made of silicon carbide is installed and fixed in the inner cavity, and the static ring 5 can move axially along the rotating shaft 8. The end face of the rotating ring 3 is pressed and sealed by the elastic element 6 installed outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com