Turbine blade crack nondestructive testing device

A turbine blade, non-destructive testing technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the huge workload brought by turbine blade detection, turbine The non-destructive testing of blades has a large workload, and the magnetostrictive tape cannot be reused, etc., so as to achieve the effect of rich types of testing, reducing the required time, and reducing the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

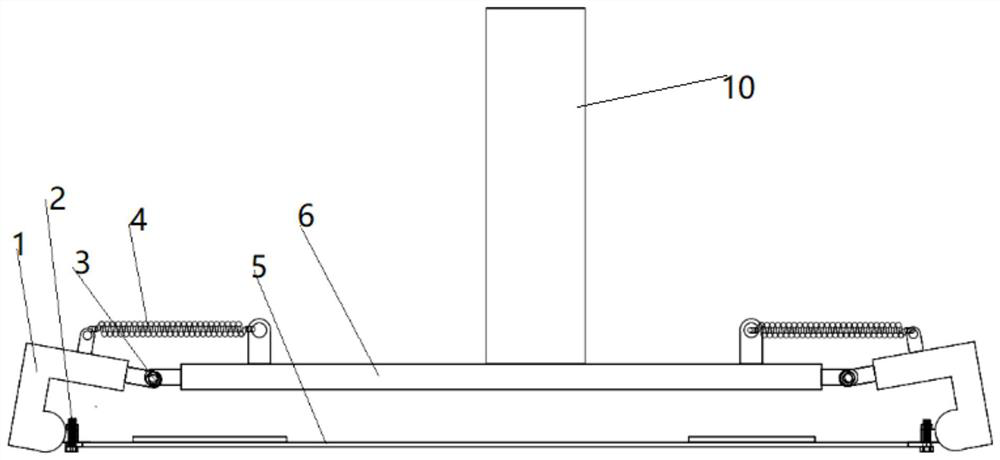

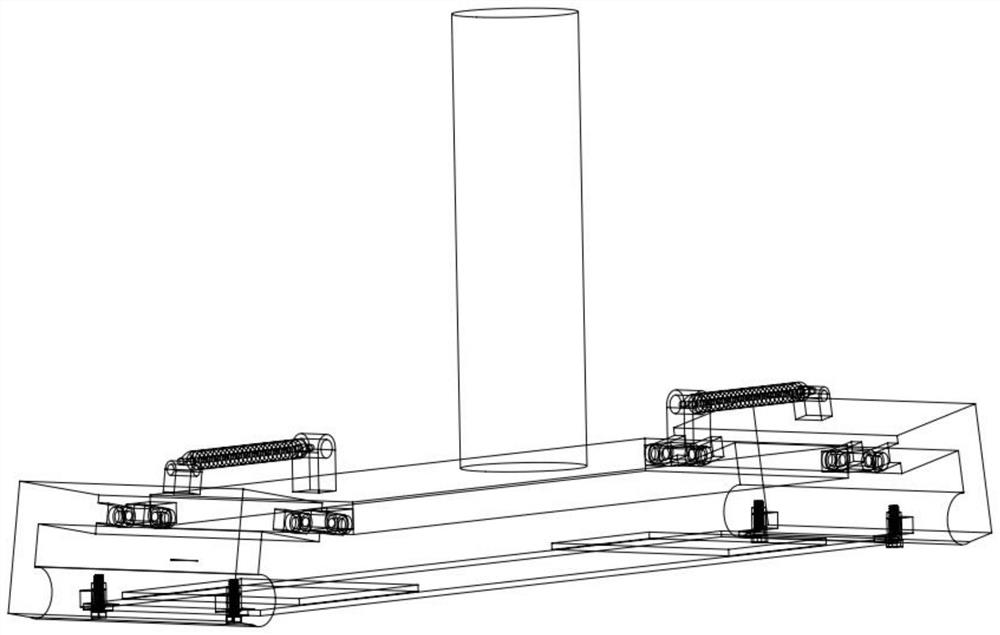

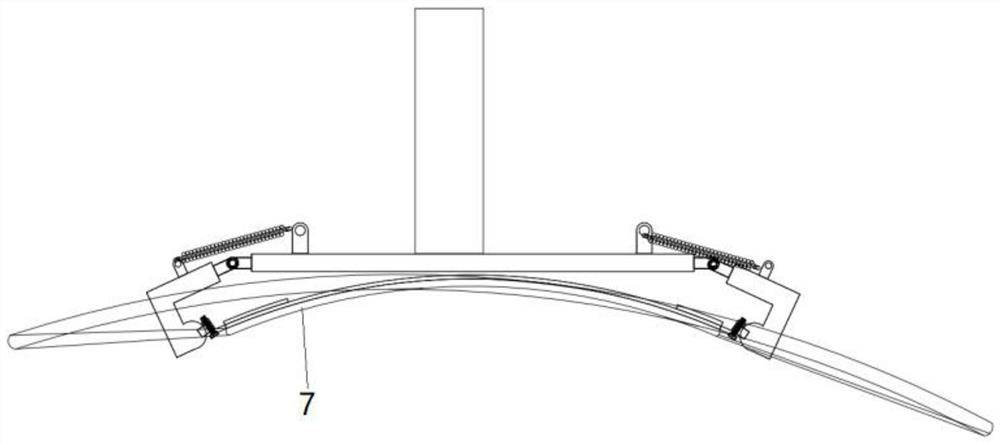

[0024] Such as Figure 1-3 As shown, the probe device of the present invention is arranged symmetrically as a whole, including a blade magnetostrictive non-destructive testing splint 1, a support device 6, a tension spring 4, a connecting bolt 2, a living hinge 3 and a composite probe 5; the two sides of the support device 6 respectively pass through The corresponding living hinge 3 is movably connected with the two splints 1, so that the splint has a certain degree of freedom, which can be changed with the width of the fixed turbine blade, increasing the type of detection blade pairs, and also adapting to the curvature of different turbine blades, so that The composite probe can be attached more closely to the turbine blades to inspect the turbine blades more strictly. Both sides of the support device 6 are also flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com