Automatic sleeve machining device and machining method thereof

A technology of automatic processing and casing, applied in the direction of manufacturing tools, decorative arts, other manufacturing equipment/tools, etc., can solve problems such as low efficiency and inconsistent product quality, and achieve the effect of uniform processing quality and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

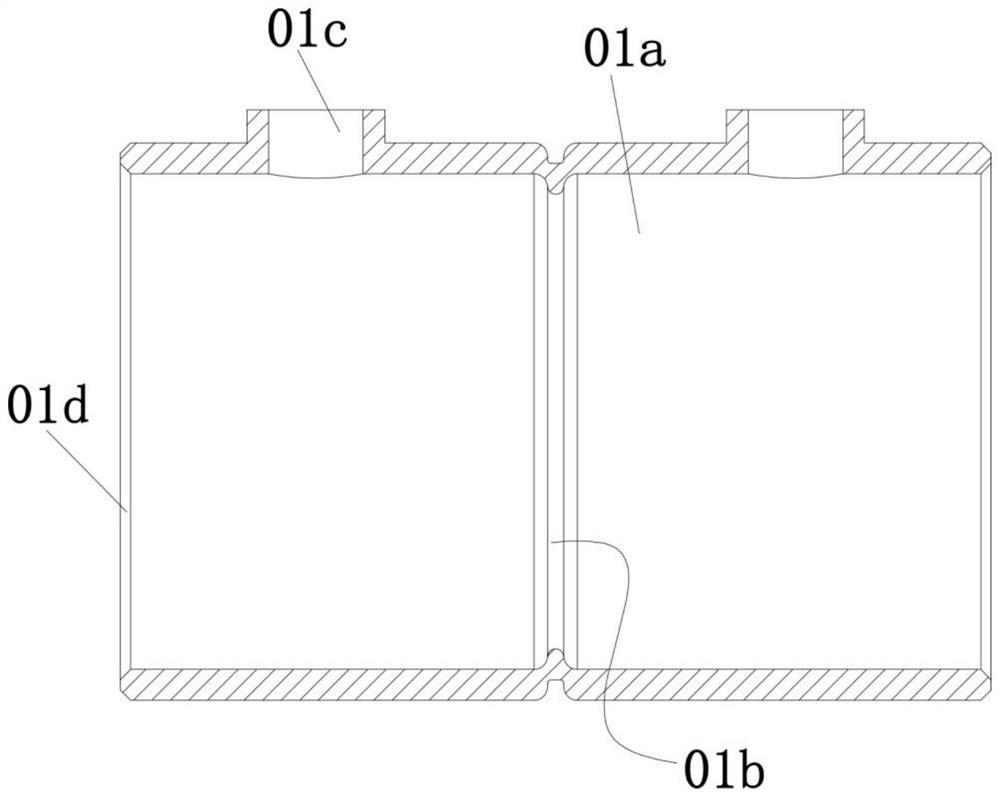

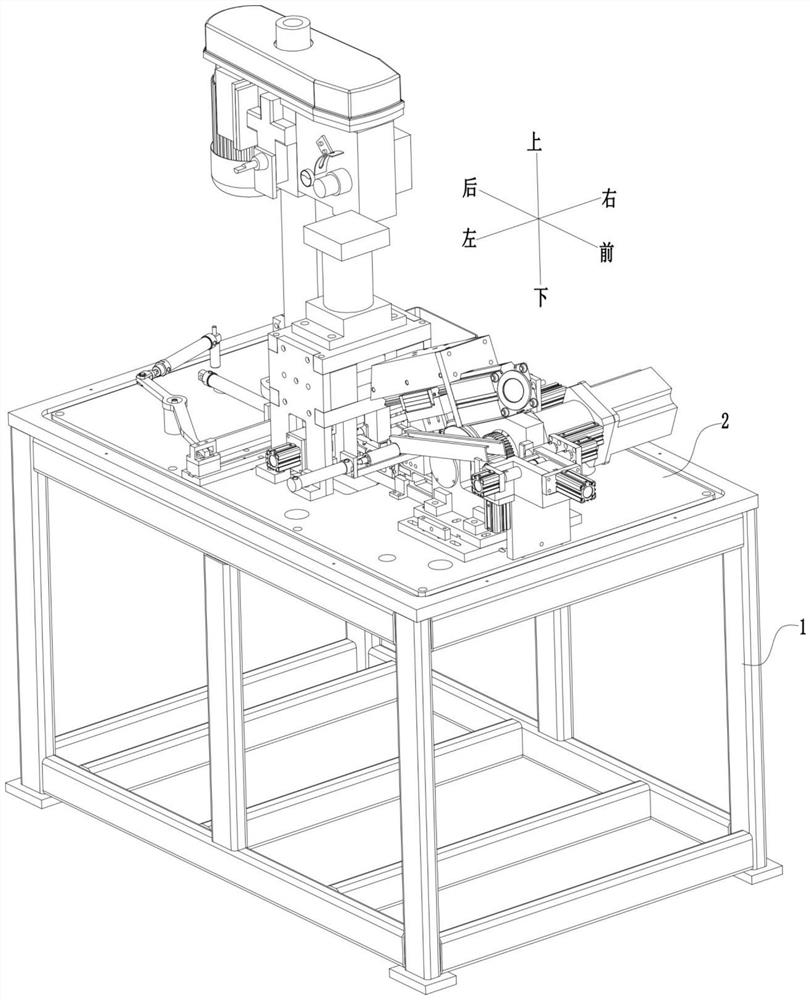

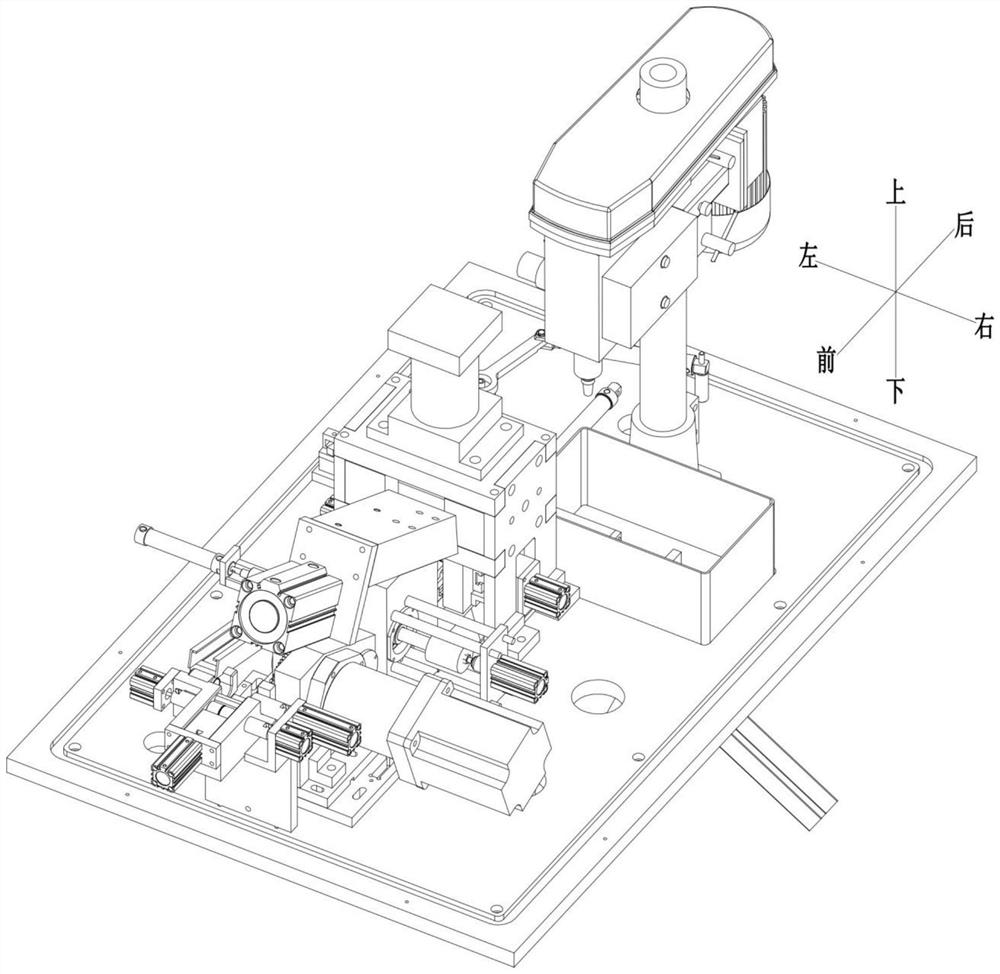

[0050] Such as Figure 1-43 As shown, a casing automatic processing device provided in this embodiment includes a table frame, and a table plate is provided on the table frame, and a detection mechanism, a casing clamping mechanism, and a character embossing mechanism are arranged on the table plate. , a bead rolling mechanism, a punching transmission mechanism, and a tapping mechanism, the detection mechanism is used to detect whether there is an inner chamfer at both ends of the sleeve, and send the sleeve with the inner chamfer at both ends into the sleeve clamping mechanism middle; the sleeve clamping mechanism is used to laterally fix the sleeve; the character embossing mechanism is used to emboss characters on the outside of the circumference of the sleeve fixed in the sleeve clamping mechanism; the rolling mechanism is used It is used to roll the inner ribs of the casing fixed in the casing clamping mechanism; the punching transmission mechanism is used to receive the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com