High-transmittance thin-wall container production injection mold grabbing device

A thin-walled container and injection mold technology, which is applied in the field of high-permeability thin-walled container production injection mold grabbing devices, can solve the problems affecting the molding quality of the container, the clamping force of the clamps, the surface wear of the container, etc. The effect of fixing firmly and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

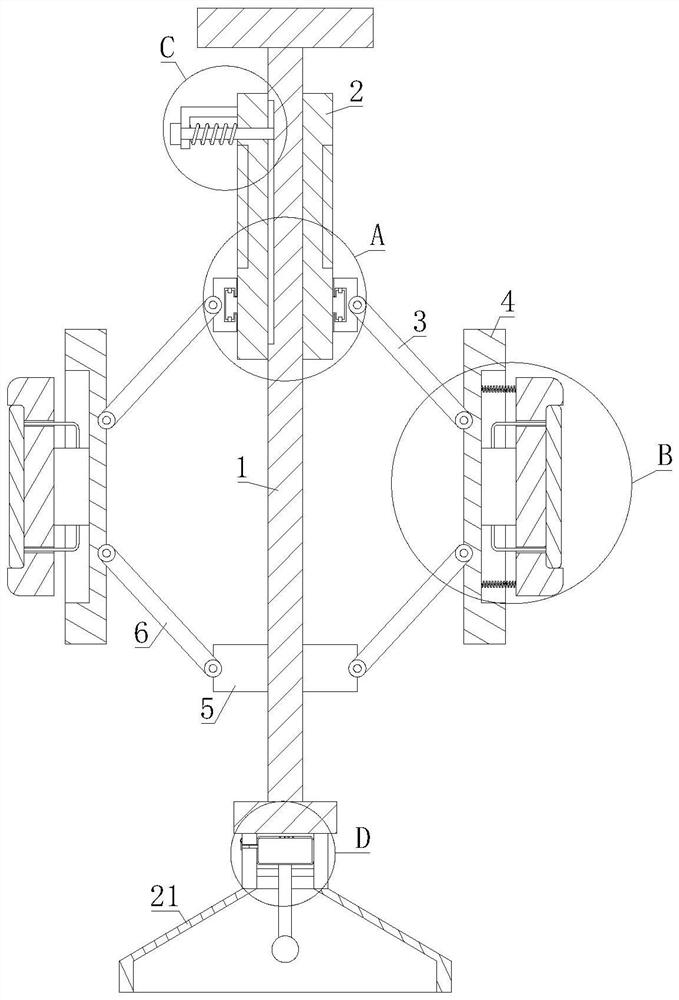

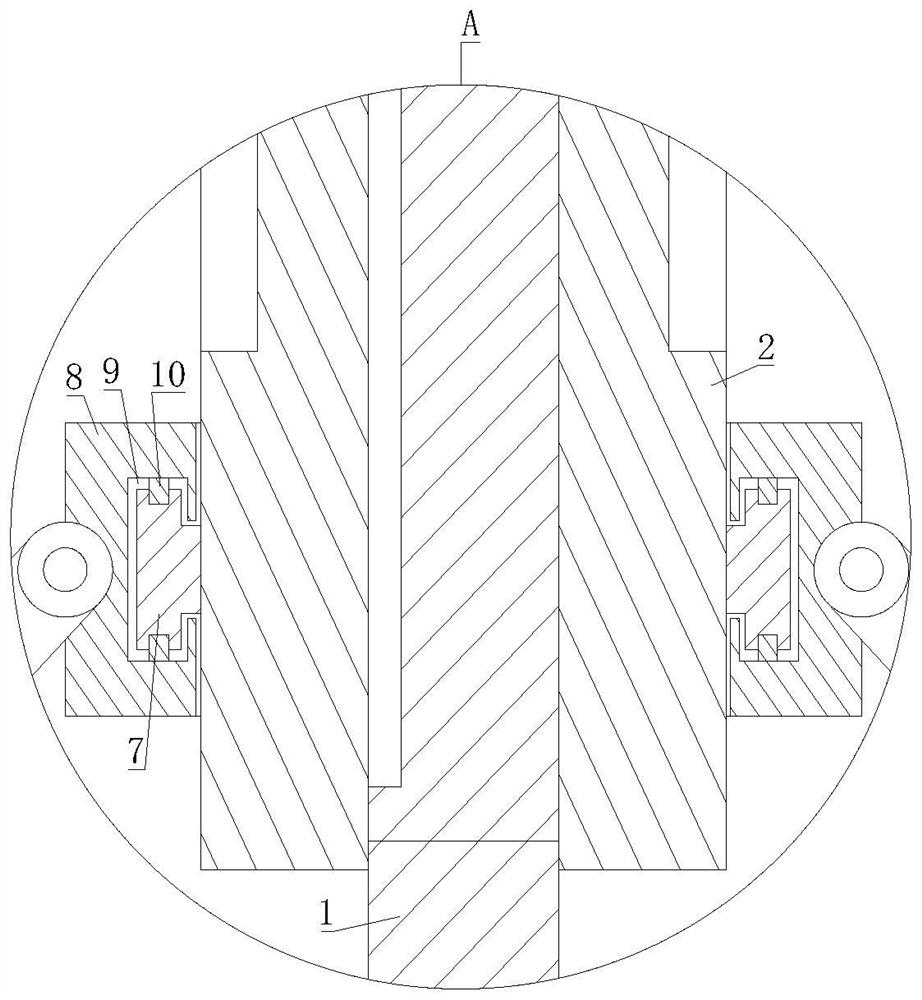

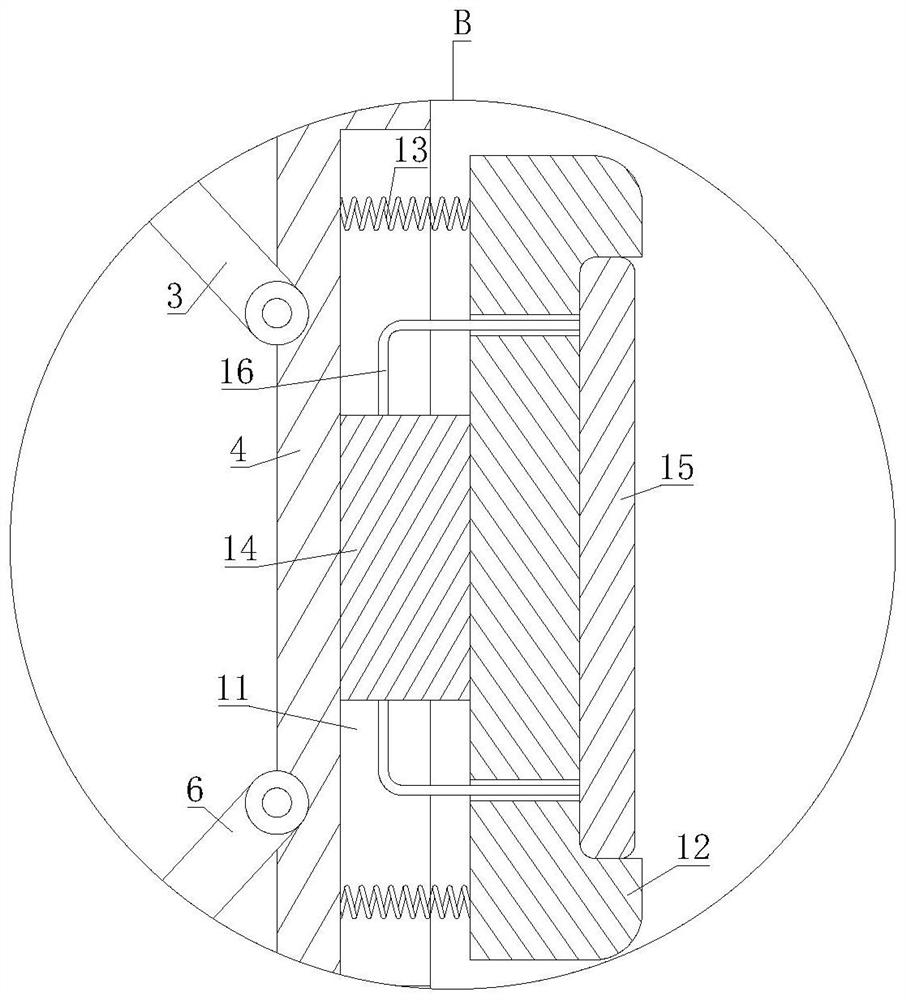

[0027] see Figure 1-6 As shown, a high-permeability thin-wall container production injection mold grasping device includes a support rod 1, the outer surface of the support rod 1 is provided with a threaded sleeve 2, and the threaded sleeve 2 and the support rod 1 For threaded connection, the outer surface of the threaded sleeve 2 is connected to a No. 1 connecting rod 3 through a rotating structure, the outer surface of the support rod 1 is fixed with a fixed ring 5, and the outer surface of the fixed ring 5 is hinged with a No. 2 connecting rod. Rod 6, the end of the No. 1 connecting rod 3 is hinged with a support block 4, which is hinged between the support block 4 and the No. 2 connecting rod 6, and the end of the support rod 1 is provided with a reinforcement structure; When the container is produced by injection molding, the container needs to be taken out after the container is cooled and formed, and the support rod 1 is put into the container and pressed to squeeze th...

Embodiment 2

[0036] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, the surface of the threaded sleeve 2 is embedded with an anti-slip sleeve 29, and the anti-slip sleeve 29 is fixedly connected to the threaded sleeve 2. The anti-slip The sleeve 29 is a flexible rubber sleeve; when the container is supported or loosened by rotating the threaded sleeve 2, the friction force between the palm and the threaded sleeve 2 can be increased by the anti-slip sleeve 29, thereby preventing hand slippage and being more conducive to threading. The rotation of the sleeve pipe 2 improves the use effect.

[0037] The working principle is that when using an injection mold to produce a container, the container needs to be taken out after the container is cooled and formed, and the support rod 1 is placed inside the container and pressed to squeeze the fixed suction cup 21. After the fixed suction cup 21 is squeezed The container can be further fixed, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com