Reduction gear injection mold

An injection mold and reduction gear technology, applied in the field of reduction gear injection molds, can solve the problems of easy loosening, high use strength, sticky materials, etc., and achieve the effects of easier removal, firm fixation, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

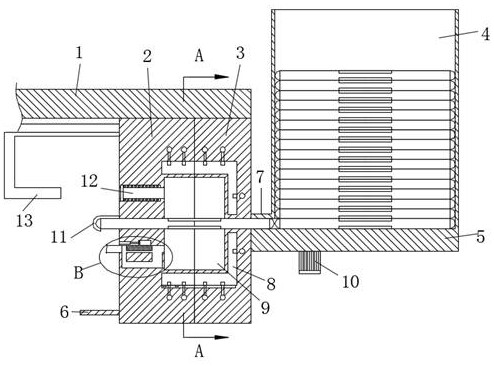

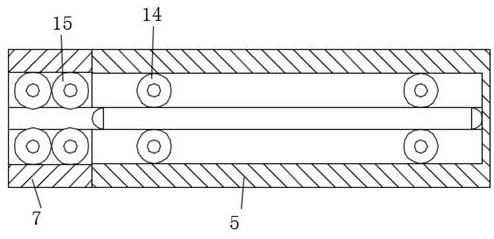

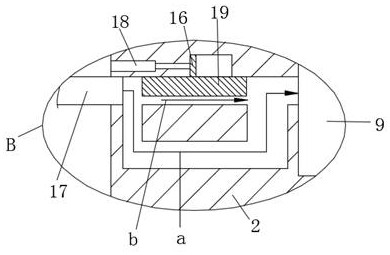

[0026] Such as Figure 1-Figure 8 As shown, in this embodiment, a reduction gear injection mold is provided, including a fixed mold 3 and a movable mold 2 arranged on one side of the fixed mold 3 to slide, the upper end of the fixed mold 3 is fixed on the bracket 1, the The bottom of the bracket 1 is provided with a slideway, and the movable mold 2 is slidably installed inside the slideway, and the inside of the bracket 1 is provided with a driving device for driving the sliding of the movable mold 2, and the driving device can drive the movable mold 2 to slide inside the slideway, that is, complete For the work of mold opening and mold closing, the driving device is a component commonly used in the production process, which is a prior art, so the present invention will not be elaborated in detail. The four corners of the fixed mold 3 are equipped with guide rods 6, and the guide rods 6 run through the moving parts. mold 2, the guide rod 6 can guide the movable mold 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com