Water meter sampling inspection device

A water meter and water pipe technology, which is applied in the field of water meter detection, can solve the problems of wasting labor costs, unable to ensure the timely and reliability of sampling inspection, and high cost, and achieve the effect of ensuring effectiveness and interval.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

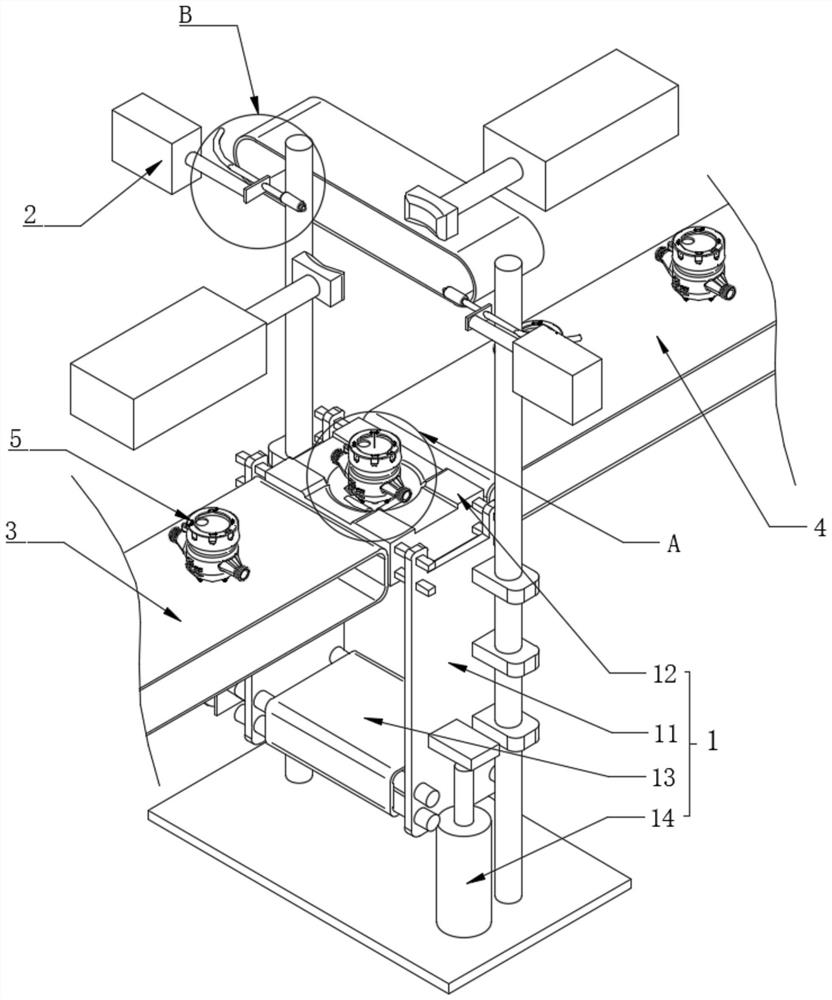

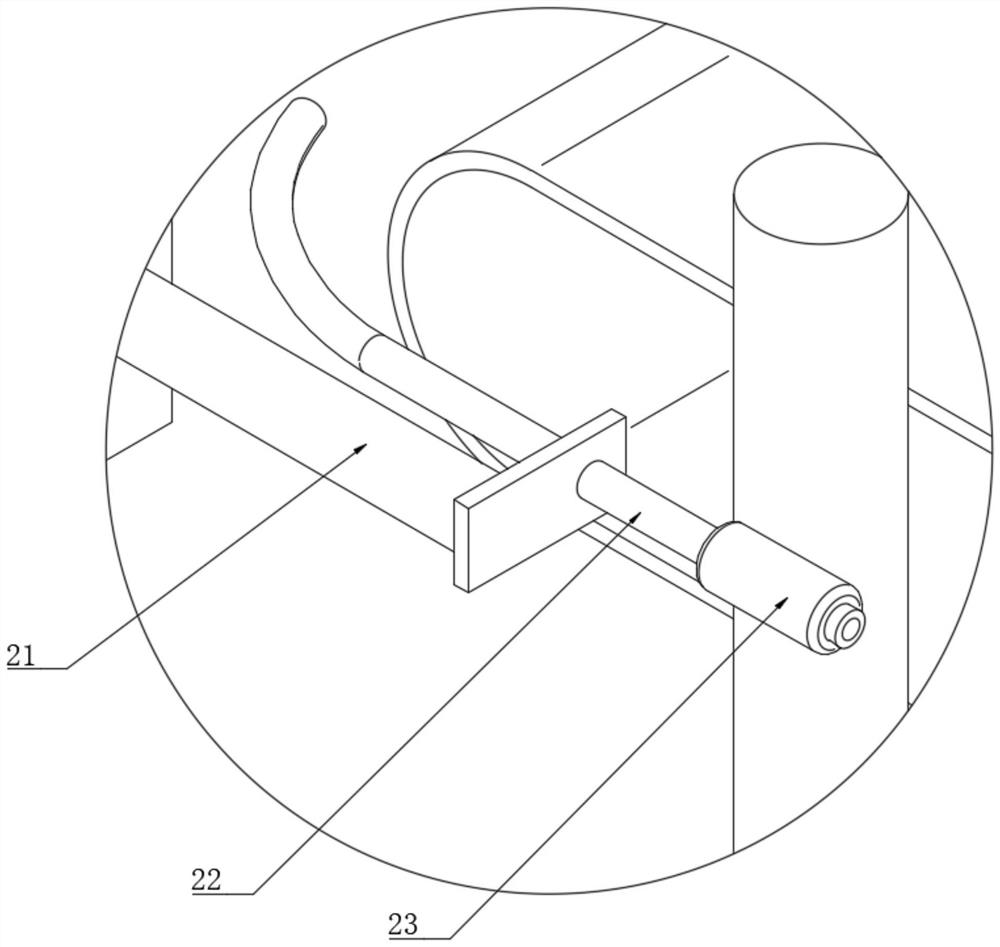

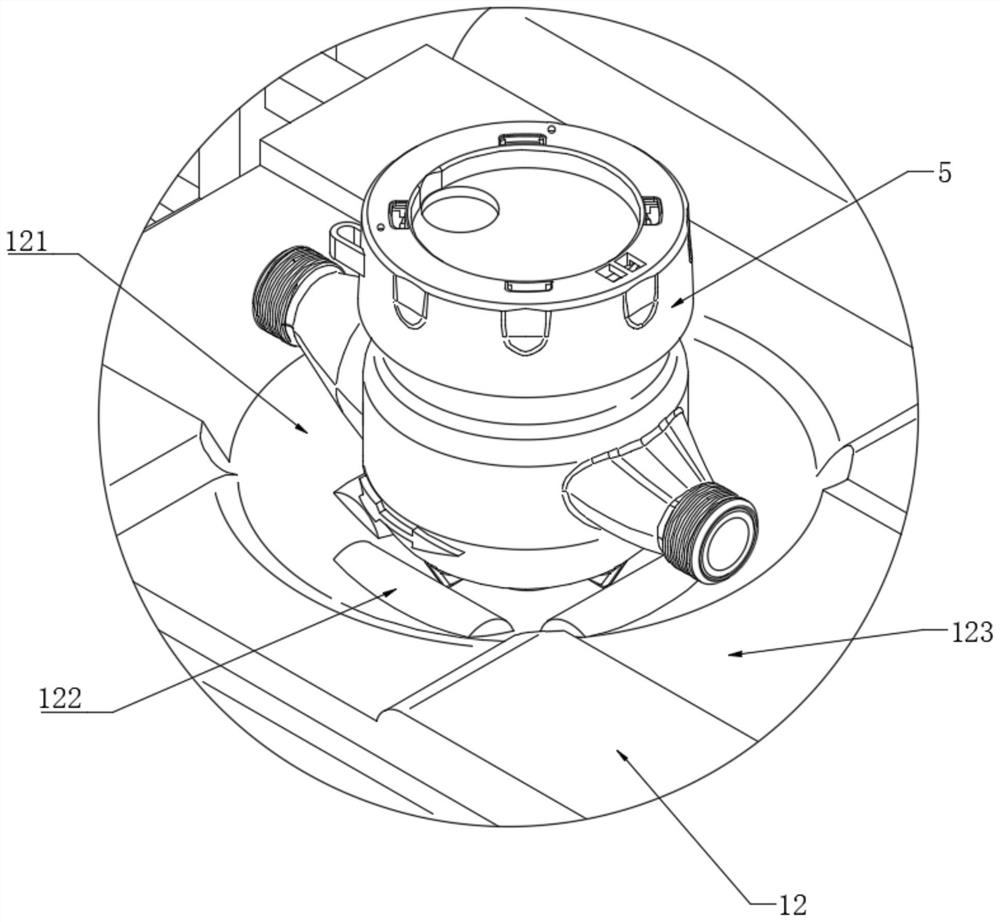

[0023] Such as Figure 1-7 As shown, the present invention includes two conveying lines, and also includes a sampling assembly 1 and a detection assembly 2, and the sampling assembly 1 is arranged between the two conveying lines, including a sliding support 11, a sampling platform 12 arranged on the sliding support 11 And the transition conveying line 13 and the driving element 14 that drives the sliding support 11 to move. When the driving element 14 drives the sampling platform 12 on the sliding support 11 to move to the station of the detection component 2, the transition conveying line 13 joins the two conveying lines.

[0024] The two conveying lines of the present invention are respectively the first conveying line 3 and the second conveying line 4, which can be used for transportation after the water meter is assembled and before packaging. Sampling inspection is carried out on the water meter packed and transported to determine whether the water meter 5 is qualified. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com