Backlight module and liquid crystal display device

A technology of backlight module and liquid crystal display panel, which is applied in the directions of optics, nonlinear optics, instruments, etc., can solve the problem of uneven display of liquid crystal display panels, and achieve the effect of improving display unevenness and ensuring the uniformity of curvature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

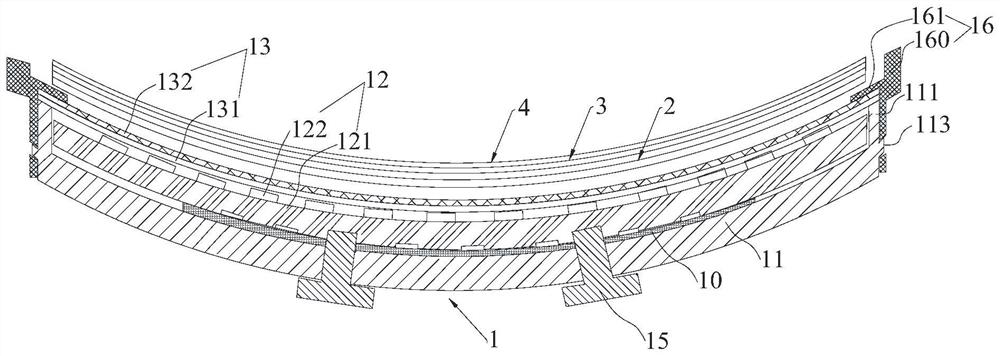

[0042] figure 1 A schematic structural diagram of a liquid crystal display device with a curved backlight module provided by the first embodiment of the present application is shown.

[0043] like figure 1 As shown, the first embodiment of the present application provides a liquid crystal display device, including a liquid crystal display panel 2 and a backlight module 1 arranged on the side of the backlight surface of the liquid crystal display panel 2, and the backlight module 1 is used to illuminate the liquid crystal display panel. 2 provide a light source.

[0044] The liquid crystal display panel 2 can be a single display panel, or a double display panel stacked in the thickness direction. When the liquid crystal display panel 2 is a dual display panel, the display panel located at the bottom layer is used for light control, and the display panel located at the top layer is used for displaying. Such setting can improve the contrast ratio of the liquid crystal display d...

no. 2 example

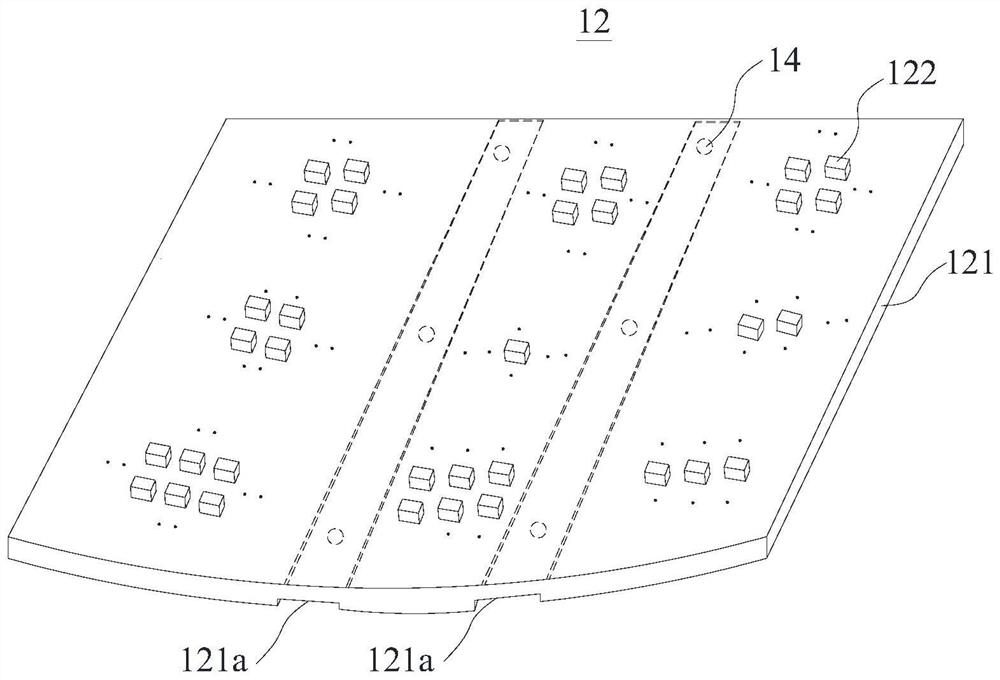

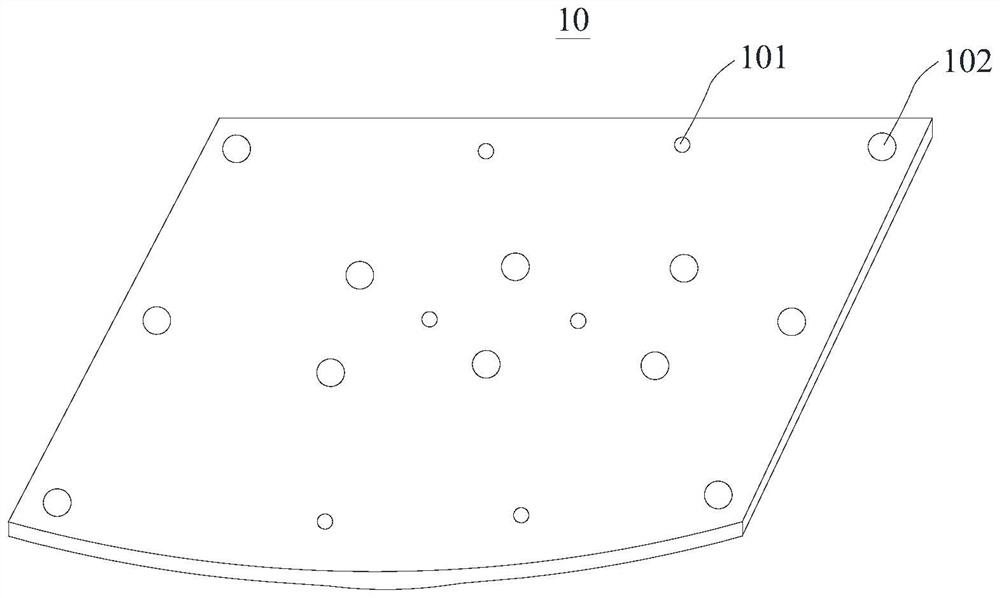

[0074] Figure 5 A schematic structural diagram of a liquid crystal display device with a backlight module provided in the second embodiment of the present application is shown, Image 6 Shows Figure 5 A schematic diagram of the assembly structure of the light board and the curved surface support in the shown backlight module.

[0075] like Figure 5 and Image 6As shown, the second embodiment of the present application also provides a backlight module 1 and a liquid crystal display device including the backlight module 1, which are the same as the first embodiment and figure 1 The shown backlight module 1 has a similar structure, and the difference lies in that the structure of the light board 121 and the curved support member 10 are different.

[0076] Specifically, the stress release portion 121 a on the lamp panel 121 is a blind groove, and the curved support 10 is accommodated in the stress release portion 121 a of the lamp panel 121 . At this time, the thickness of...

no. 3 example

[0079] Figure 7 A schematic structural diagram of a liquid crystal display device with a backlight module provided by the third embodiment of the present application is shown.

[0080] like Figure 7 As shown, the liquid crystal display device provided with the backlight module 1 provided by the third embodiment of the present application is the same as the first embodiment and figure 1 The shown liquid crystal display device with the backlight module 1 has a similar structure, the difference is that the fixed position of the optical component 13 is different, so that the light mixing distance between the optical component 13 and the light emitting element 122 becomes larger.

[0081] Specifically, the edge of the backlight panel 11 is provided with a side wall 111 extending along the light emitting direction, and the plastic frame 16 is arranged around the outer peripheral side of the side wall 111. The extended first support portion 161 , the body portion 160 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com