Steel picture defect detection method in industrial production based on self-supervised contrast characterization learning technology

A defect detection and industrial production technology, applied in neural learning methods, image enhancement, image analysis, etc., can solve problems such as relying on a large amount of label data, and achieve excellent defect detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

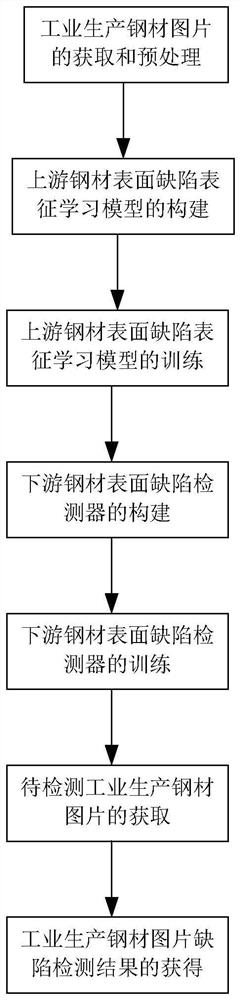

[0095] Such as figure 1 As shown, a kind of steel picture defect detection method in industrial production based on self-supervised comparative representation learning technology of the present invention comprises the following steps:

[0096] The first step is the acquisition and preprocessing of industrial production steel pictures: obtain labeled and unlabeled industrial production steel pictures and perform preprocessing.

[0097] (1) Obtain pictures of steel produced in industry;

[0098](2) Carry out data enhancement processing on industrial production steel pictures:

[0099] Firstly, all the industrial production steel pictures are adjusted to the size of 224x224, and then random cropping and random horizontal flip are appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com