Battery system for industrial machine

An industrial, battery pack technology, applied in the direction of batteries, battery pack components, battery/battery traction, etc., can solve problems such as increasing the risk of battery failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Both the foregoing general description and the following detailed description are exemplary and explanatory only and do not limit the features that are claimed. As used herein, the terms "comprises," "comprising," "having," "including" or variations thereof are intended to encompass a non-exclusive inclusion such that a process comprising a list of elements A method, article, or apparatus includes not only those elements, but may include other elements not expressly listed or inherent to such a process, method, article, or apparatus. Additionally, in this disclosure, relative terms such as "about," "approximately," "substantially," and "approximately" are used to denote a possible variation of ±10% of the stated value.

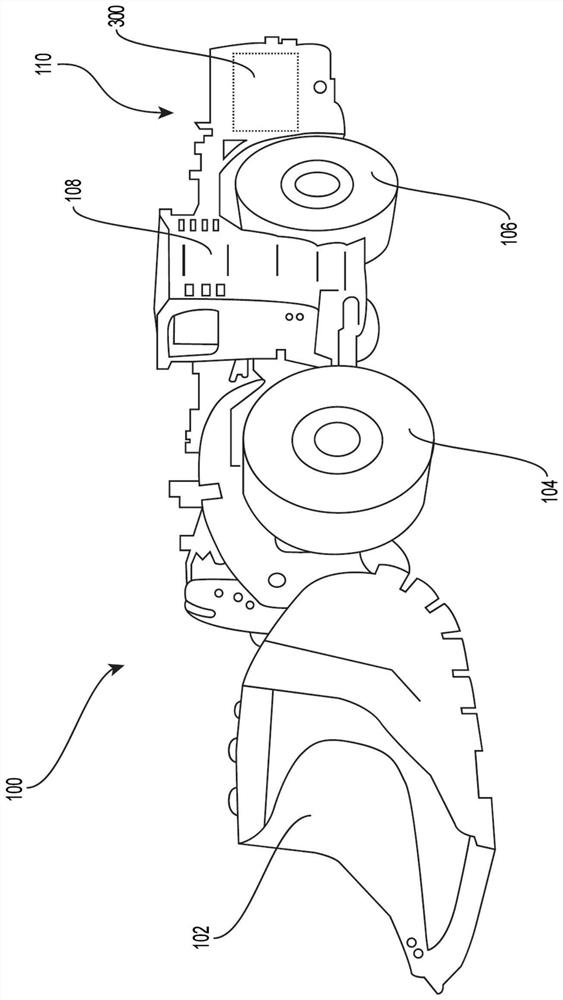

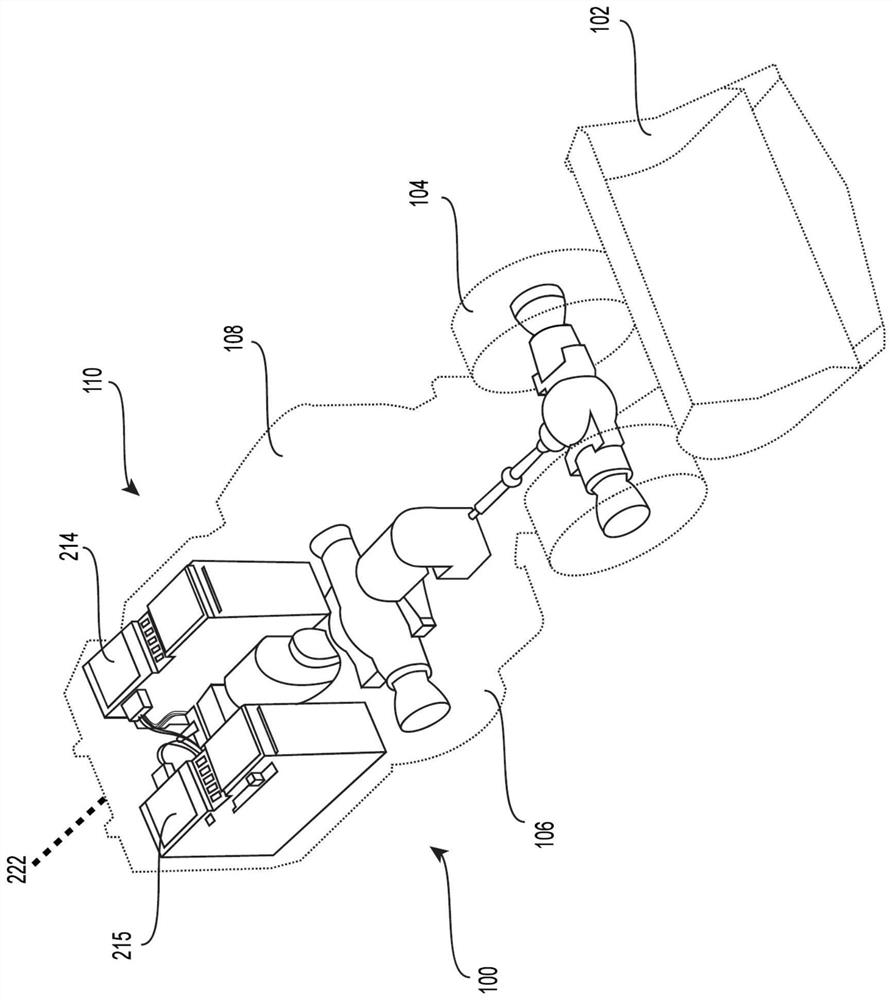

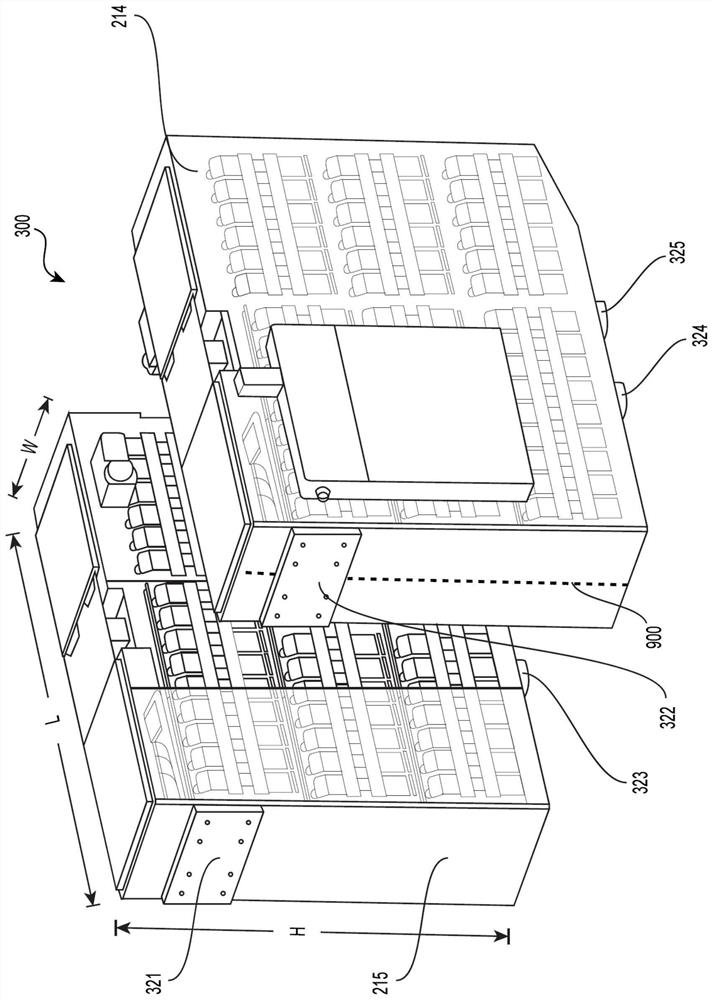

[0022] figure 1An exemplary industrial vehicle is shown in the form of a loading and unloading (LHD) vehicle 100 including a dump bucket 102 , wheels 104 , 106 , an operator control bay 108 and a vehicle body 110 . Although the following discussion re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com