Laser cutting method

A laser cutting and laser technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of burns at the starting point and end point of workpiece cutting, the contour cannot meet the size of the cutting surface roughness, and the appearance and contour size of the workpiece are unqualified. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

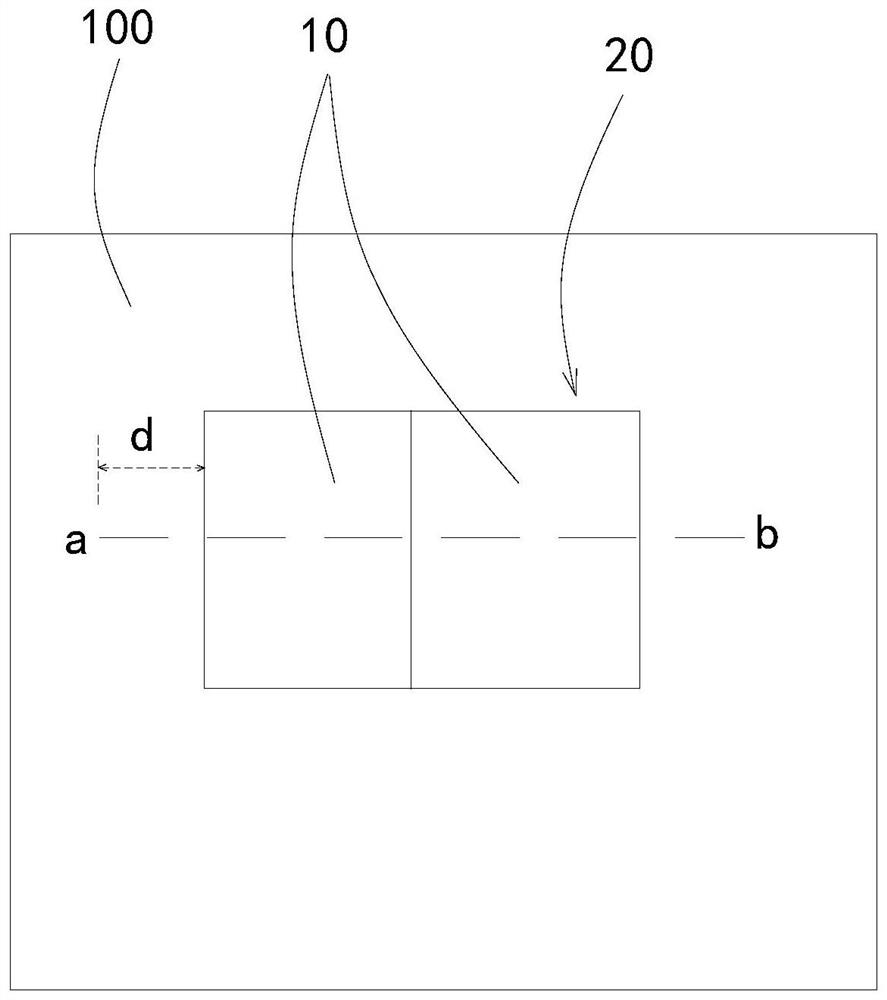

[0036] Please refer to figure 1 , the laser cutting method described in the embodiment of the present invention, comprises the following steps:

[0037] S1. Splice the two products 10 along the length direction by using the jig 100 to form the cutting area 20 .

[0038] S2. Setting a cutting path, a starting point a, and an ending point b. Both the starting point a and the ending point b are located outside the cutting area 20 and are located at different positions.

[0039] S3. Turn on the laser, and cut the cutting area 20 according to the cutting path.

Embodiment 2

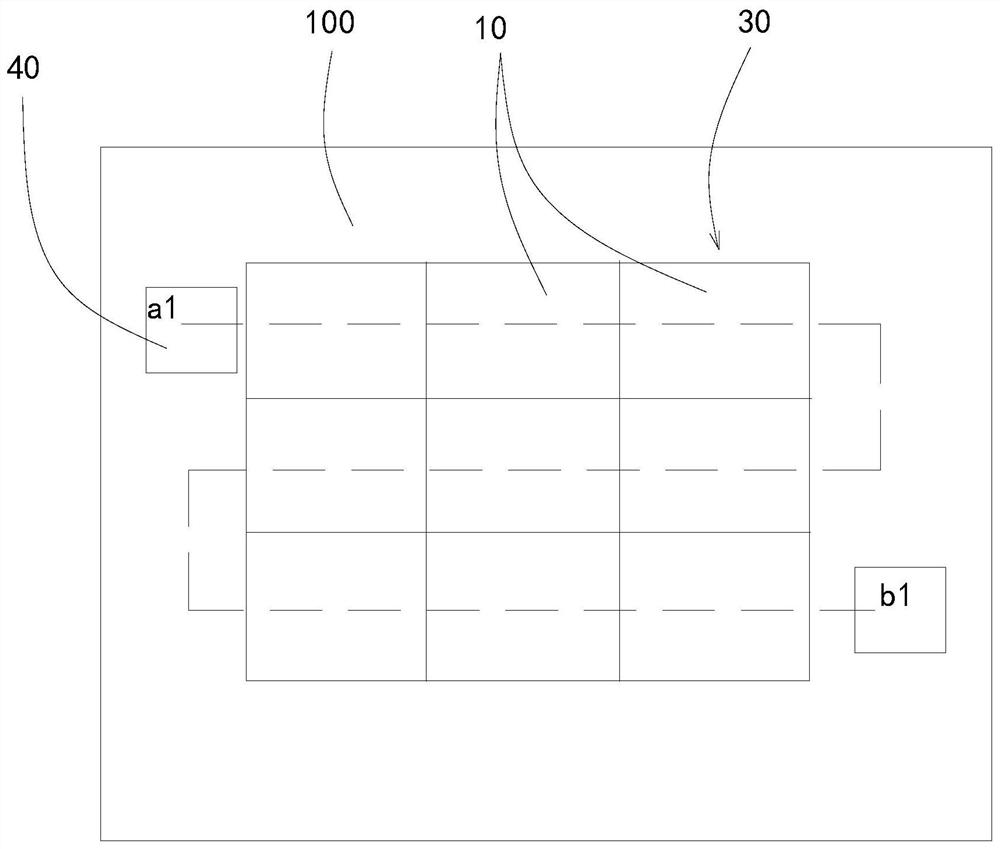

[0041] Please refer to figure 2 , the laser cutting method described in the embodiment of the present invention, comprises the following steps:

[0042] S1. Using the jig 100 to splice multiple products 10 in an array to form a cutting area 30 .

[0043] S2, setting cutting path, starting point a1 and end point b1, starting point a1 and end point b1 are located outside the cutting area 30 and both are located in different positions; A waste pad 40 is provided.

[0044] S3. Turn on the laser, and cut the cutting area 30 according to the cutting path.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com