A high-strength, high-temperature resistant, fire-resistant and heat-insulating material

A technology of heat insulating material and fireproof material, which is applied in the field of high-strength and high-temperature resistant fire-proof heat-insulating material and fire-proof heat-insulating material, can solve the problems of peeling off of polymer resin, difficult burning of fire-proof material at high temperature, loss of fire-proof protection, etc. Insulation effect, crack prevention effect, effect of increasing thermal contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

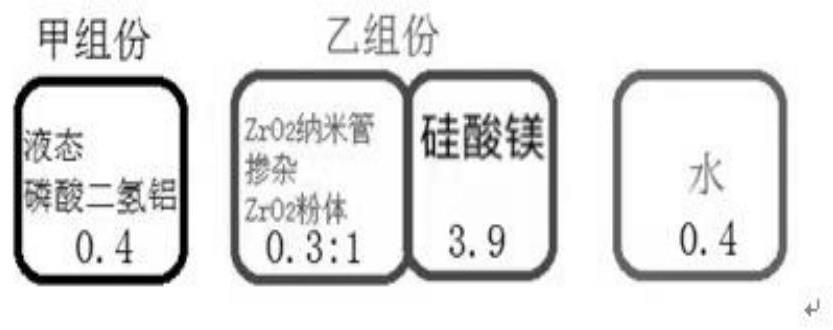

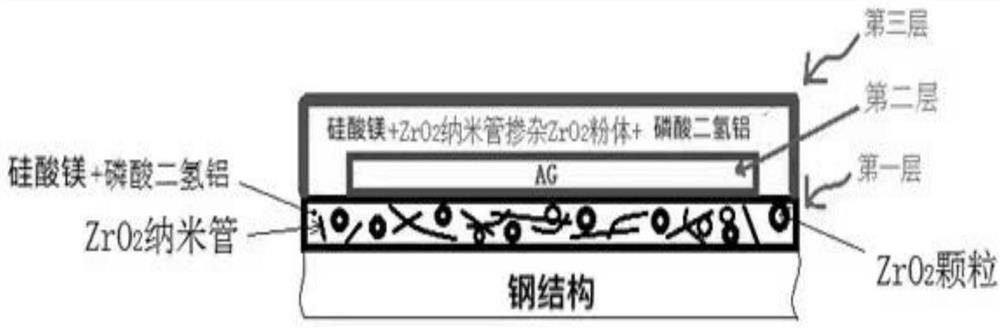

[0046] This embodiment specifically provides a high-strength, high-temperature, fire-resistant and heat-insulating material, including liquid aluminum dihydrogen phosphate, ZrO 2 Nanotube-doped ZrO 2 Granular powder, magnesium silicate, water, mass ratio such as figure 1 shown as 0.4:1.3, respectively (where ZrO 2 Nanotube: ZrO 2 Granular powder = 0.3:1 mass ratio): 3.9:0.4.

Embodiment 2

[0048] This embodiment specifically provides a high-strength, high-temperature-resistant, fire-resistant and heat-insulating material, including liquid aluminum dihydrogen phosphate, ZrO 2 Nanotube-doped ZrO 2 Granular powder, magnesium silicate, the mass ratio is 0.8:1.3 (wherein ZrO 2 Nanotube: ZrO 2 Granular powder = 0.3:1 mass ratio): 3.9.

Embodiment 3

[0050] This embodiment specifically provides a high-strength, high-temperature-resistant, fire-resistant and heat-insulating material, including liquid aluminum dihydrogen phosphate, ZrO 2 Nanotube-doped ZrO 2 Granular powder, 1:1 mass ratio of magnesium silicate and calcium silicate, water, the mass ratio is 0.4:1.3 (wherein ZrO 2 Nanotube: ZrO 2 Granular powder = 0.3:1 mass ratio): 3.9:0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com