Multi-mode onboard rock hydraulic splitting machine

A multi-mode, splitting machine technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of single splitting mode, unable to deal with rocks, difficult to achieve splitting, etc., and achieve smooth splitting process , improve adaptability, improve the effect of splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

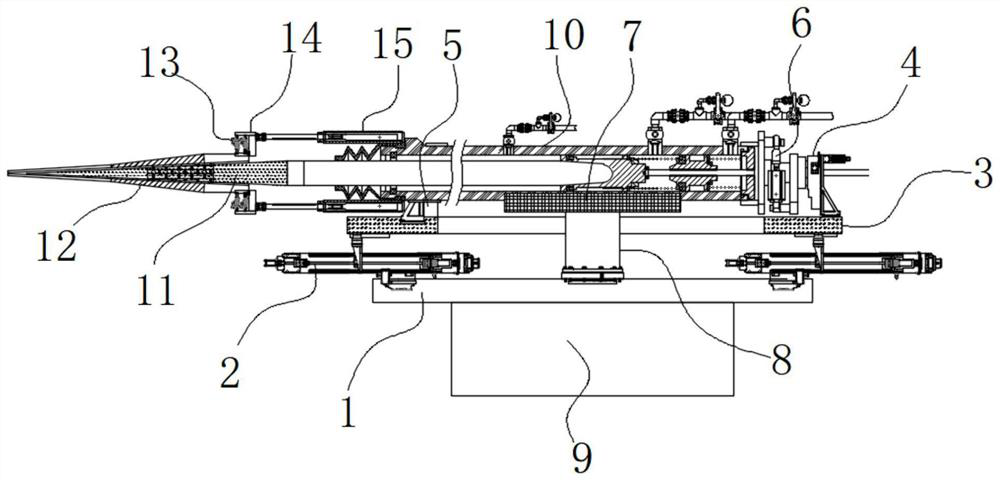

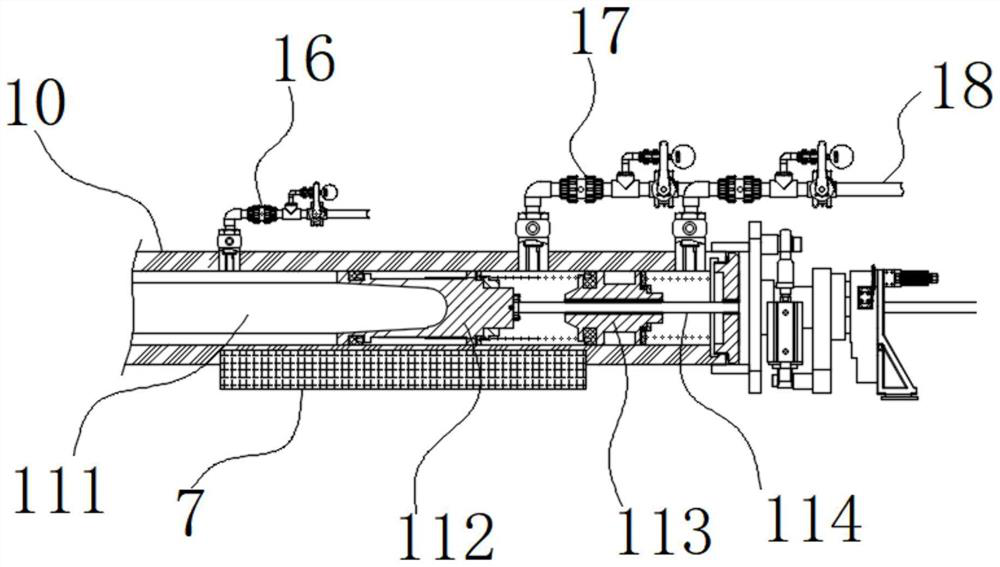

[0029] see Figure 1~4 , the present invention provides a multi-mode airborne hydraulic rock splitting machine, comprising:

[0030] Outer cylinder 10, its left end is rotatably arranged on the support seat 2 5, and its right end tail is rotatably arranged on the support seat 1 4;

[0031] Drive plate 3, the middle part of which is provided with a relief slot, and the left and right sides are respectively used to install support seat 2 5 and support seat 1 4;

[0032] Adjusting rod 6, one end of which is hinged to the support base 4, and the other end is hinged to the outer cylinder;

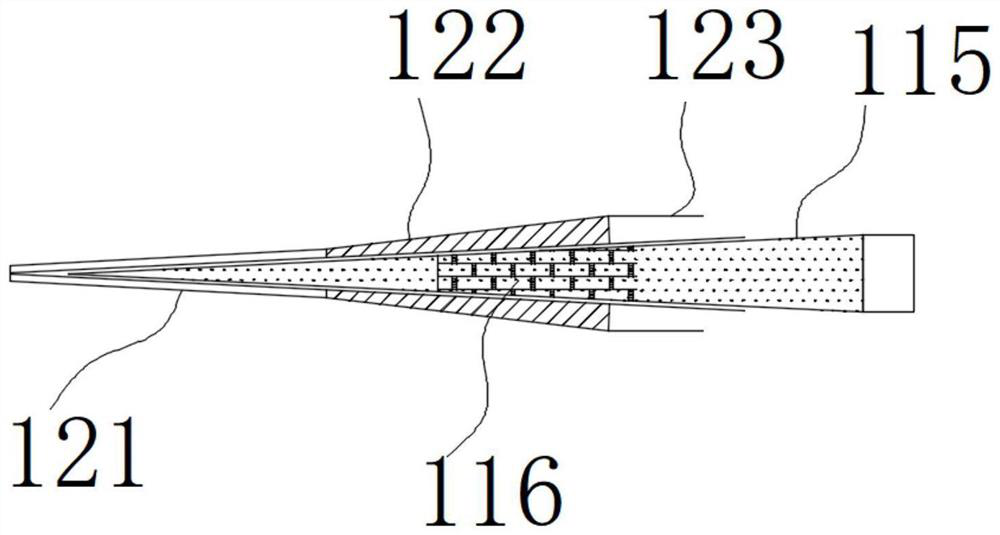

[0033] an inner drive rod 11, which is coaxially arranged inside the outer cylinder 10 and capable of moving along the axial direction of the outer cylinder 10; and

[0034] The symmetrically arranged outer splitting head 12, the right side of which adopts the reset device 13 to carry out radial sliding and is arranged in the ring seat 14, and the ring seat 14 is sleeved on the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com