Device and method for blocking pipeline under pressure without stopping conveying and moving fire

A technology for pipelines and plugging holes, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of inability to weld large currents, limitations of technical environmental factors, failure of plugging under pressure, etc., and achieve the construction process. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

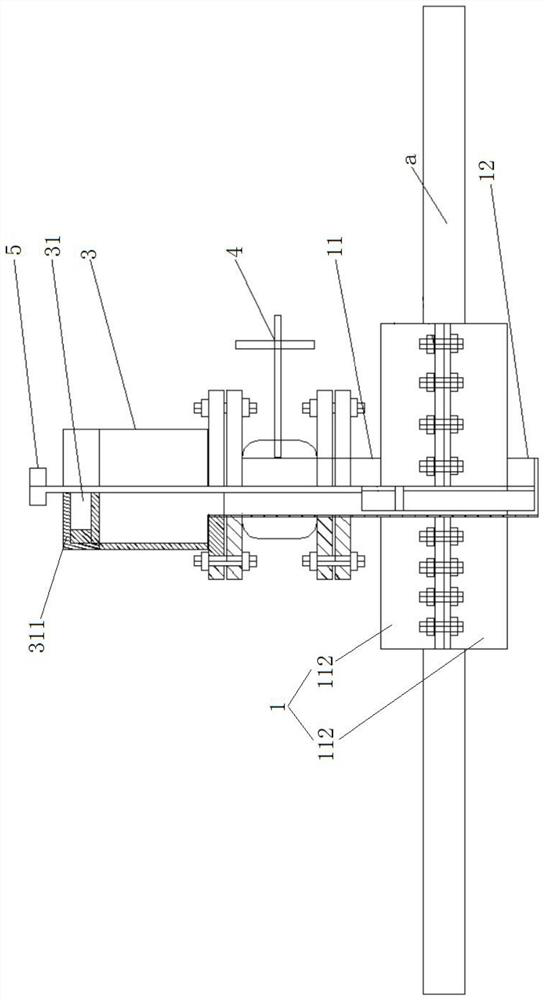

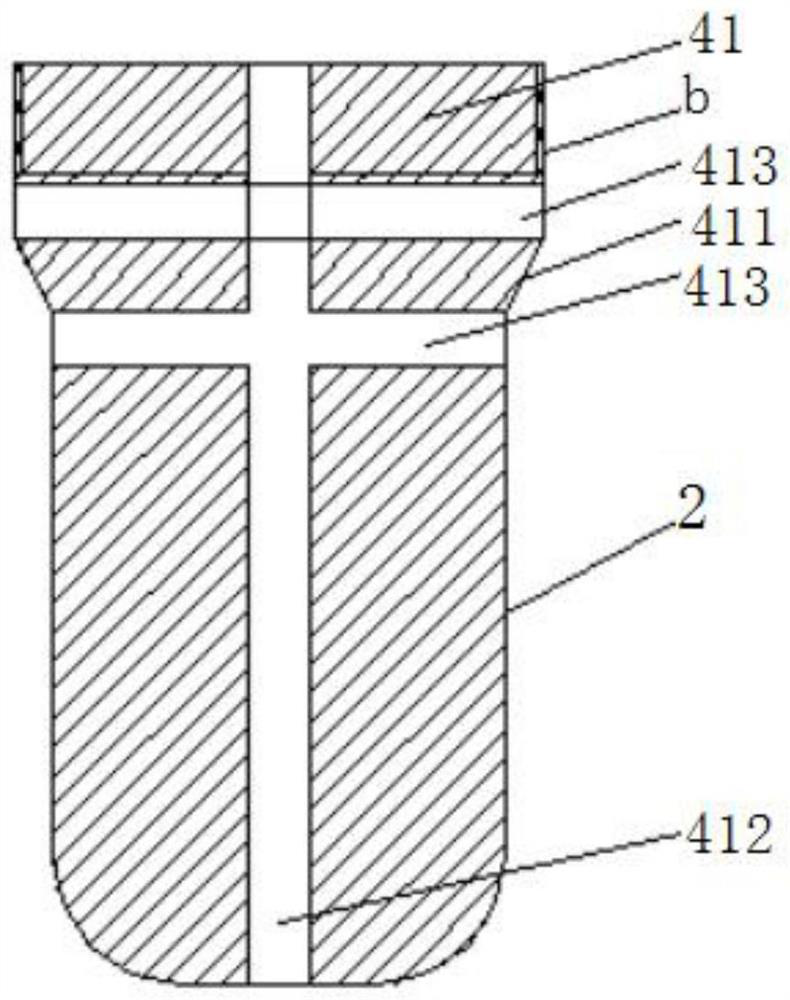

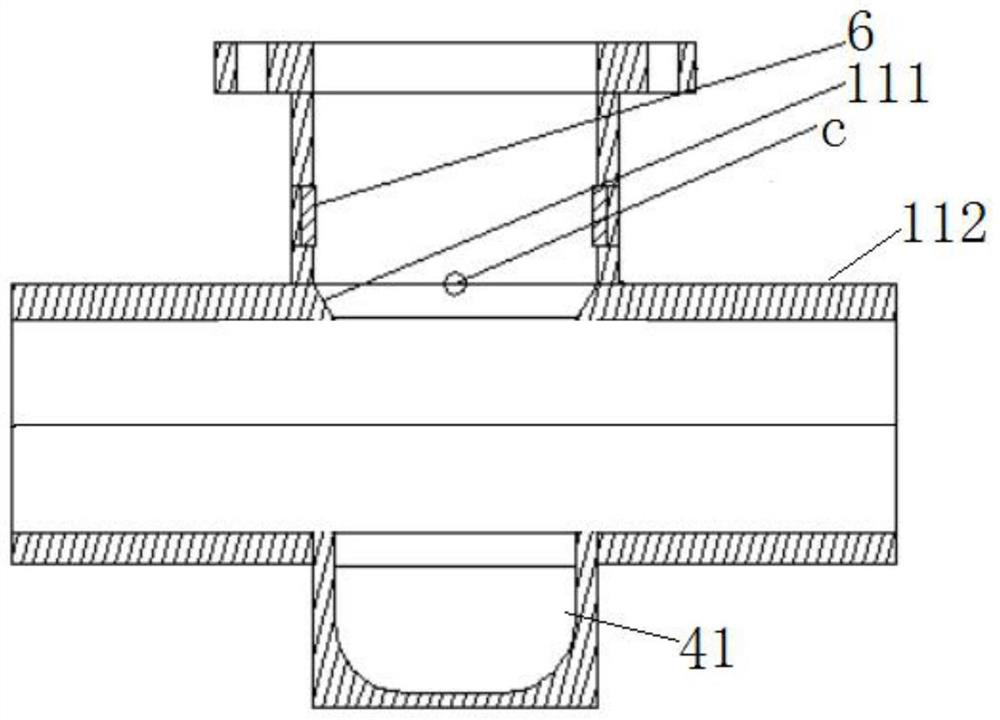

[0038] Example: such as figure 1 , 2 As shown in , 3, the device for non-stop pipeline non-fired and pressure plugging of the present embodiment includes an outer plugging pipe 1, an inner sealing body 2, a plugging working cylinder 3 and a valve 4, and the above-mentioned outer plugging pipe 1 is used for The sealing sleeve is set outside the pipeline plugging point, and the middle parts of both sides are respectively coaxially provided with plugging holes 111, and the outer periphery of one of the above-mentioned plugging holes 111 is sealed with a connecting pipe 11 perpendicular to the above-mentioned outer plugging pipe 1, The outside of another one of the above-mentioned plugging holes 111 is sealed with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com