Cooking bench for simulated kitchen laboratory and simulated kitchen laboratory

A laboratory and cooktop technology, applied in the field of cooktops and simulated kitchen laboratories, can solve the problems of no reference meaning, troublesome operation, waste of time, etc., and achieve the effect of improving space utilization, solving back and forth switching, and convenient test operation

Pending Publication Date: 2022-04-01

GUANGDONG MACRO GAS APPLIANCE

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, option 1) is inaccurate due to the deviation between the center of the pot and the center of the 750mm hood, resulting in inaccurate test results and basically no reference value

Solution 2) has the problems of troublesome operation, time-consuming replacement and low test efficiency

Option 3) requires a larger laboratory or set up two laboratories, which has the problem of being idle and multiplying the application cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0050] A simulated kitchen laboratory, in which a stove 1, a cabinet 9, a range hood to be tested 10, a data acquisition device, and a door 11 are arranged, the main innovation of which is that the stove 1 is as follows The stove top described in embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

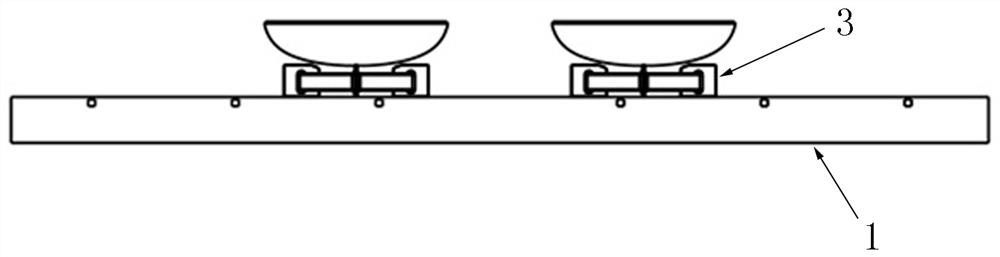

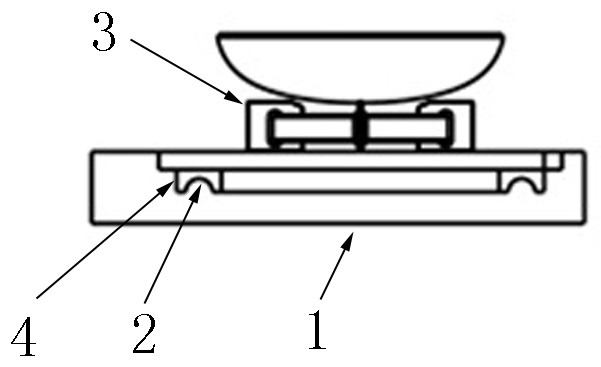

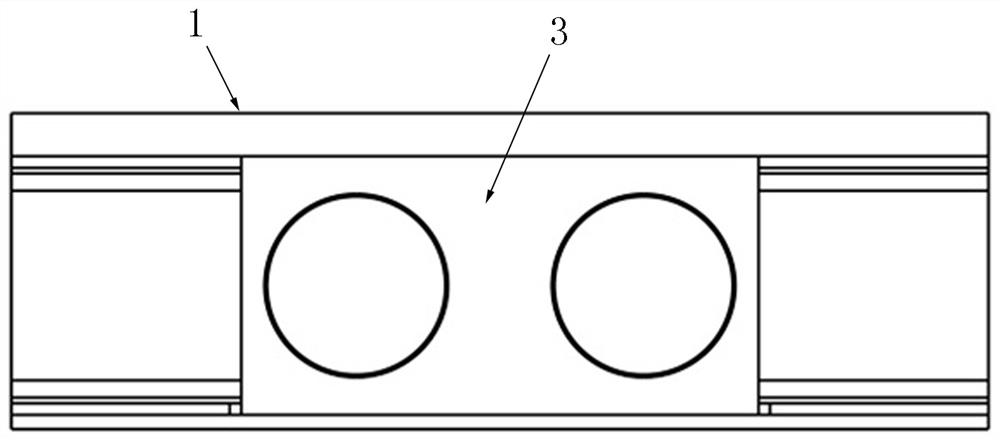

The invention relates to the technical field of range hood detection, and discloses a cooking bench for a simulated kitchen laboratory and the simulated kitchen laboratory, a sliding rail is arranged on the cooking bench, a stove is in sliding connection with the sliding rail through a corresponding sliding block, and a positioning block for positioning the stove on the sliding rail is arranged corresponding to the stove. The cooking bench provided by the invention can be universally used for testing the oil smoke suction effect of range hoods with different specifications such as 900mm and 750mm, is simple in structure and convenient to test and operate, effectively improves the space utilization rate of a simulated kitchen laboratory, solves the problem that the test result is inaccurate when any one of fixed double-hole stoves is used for testing a single-pot small type, and improves the test efficiency. The problem of back-and-forth switching of single-hole and double-hole stoves

Description

technical field [0001] The invention relates to the technical field of range hood detection, in particular to a stove for simulating a kitchen laboratory and a simulating kitchen laboratory. Background technique [0002] A simulated kitchen laboratory is required for performance testing of range hoods. The simulated kitchen laboratory is mainly used to simulate the actual cooking environment of the user, so as to test the range hood's range hood effect through experiments. At present, according to the different horizontal dimensions, the range hoods are mainly divided into 900mm and 750mm, which are used for binocular stoves and single-eye stoves respectively. [0003] However, most of the stoves in the existing simulated kitchen laboratories are fixed double-eye stoves. When testing the smoke effect of the 900mm range hood, the left and right stoves are used for the test respectively. When testing the smoking effect of the 750mm range hood, there are mainly The following ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M99/00

Inventor 艾穗江刘晗莹文士胜

Owner GUANGDONG MACRO GAS APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com