Alternating rock breaking test system based on laser melting-supercooled liquid jet

A test system and liquid jet technology, which is applied in the field of rock mass structure testing, can solve the problems of increasing difficulty in rock breaking, complex and changeable geological conditions, and inability to further increase the rock breaking rate, so as to reduce the difficulty of rock breaking and improve the The effect of rock velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

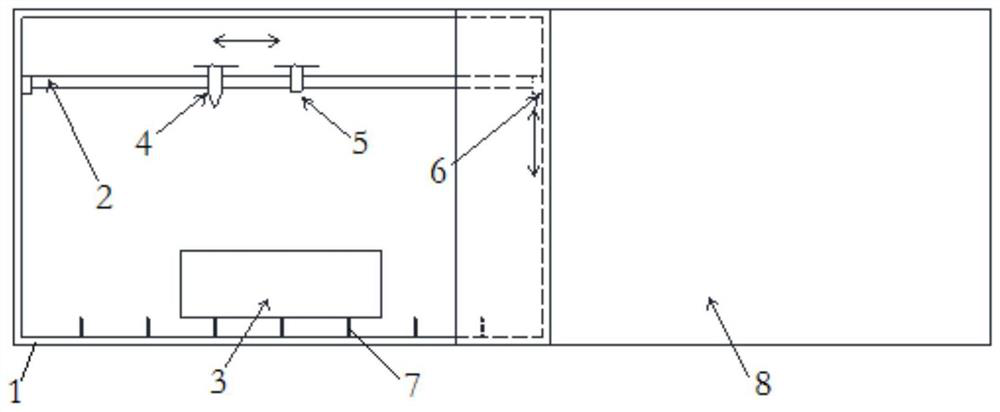

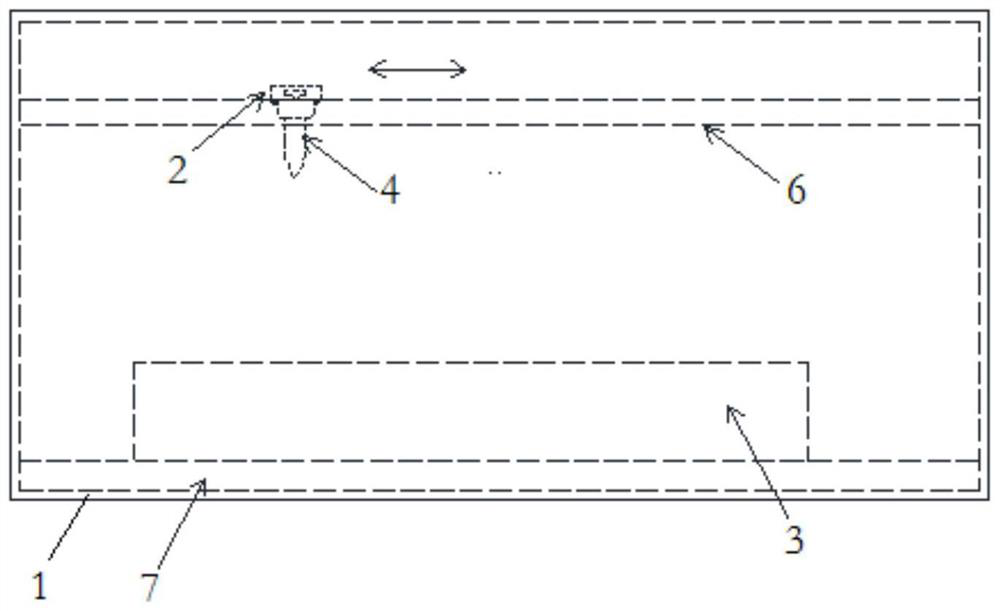

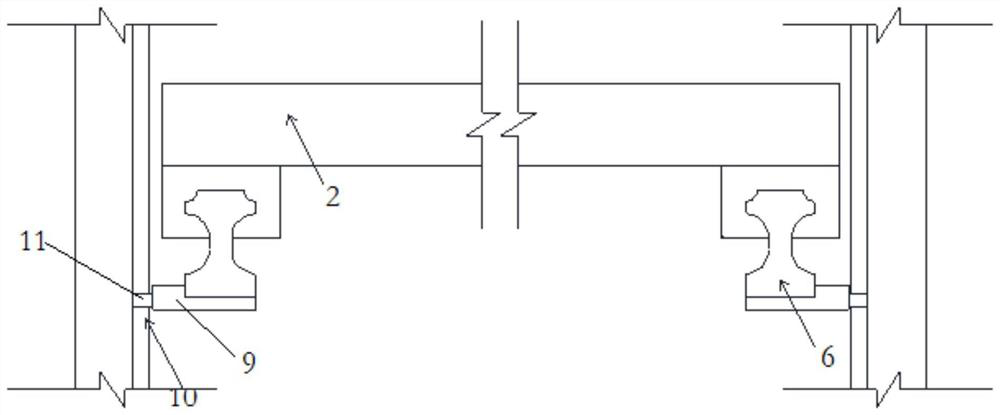

[0048] Such as Figure 1-7As shown, the present embodiment 1 provides a kind of alternating rock-breaking test system based on laser melting-supercooled liquid jet. The test system is used to carry out high and low temperature alternating failure test on the rock sample 3. The test system includes: a box body 1. The bottom of the box 1 is provided with a rock sample 3 for alternating damage, and the side wall of the box 1 is provided with an inlet and an outlet connected to the inside of the box 1; the instrument installation platform 2, the instrument installation platform 2 is a beam structure , the beam structure of the instrument installation platform 2 is provided with a laser 5 and a nozzle 4, the nozzle 4 is connected to an external water pump through a connecting pipe, the laser 5 and the nozzle 4 can move in the length direction of the beam structure, and the two The ends are correspondingly arranged on a pair of opposite side walls in the box body 1; the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com