System and method for detecting foam inhibition property and defoaming property

A detection system and defoaming technology, applied in the direction of material inspection products, etc., can solve problems such as inability to quantify, difficult to clean, inaccurate quantitative data of coating foam suppression and defoaming, and achieve the effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in connection with embodiments. The following embodiments are for more clearly illustrative of the technical solutions of the present invention without limiting the scope of the invention.

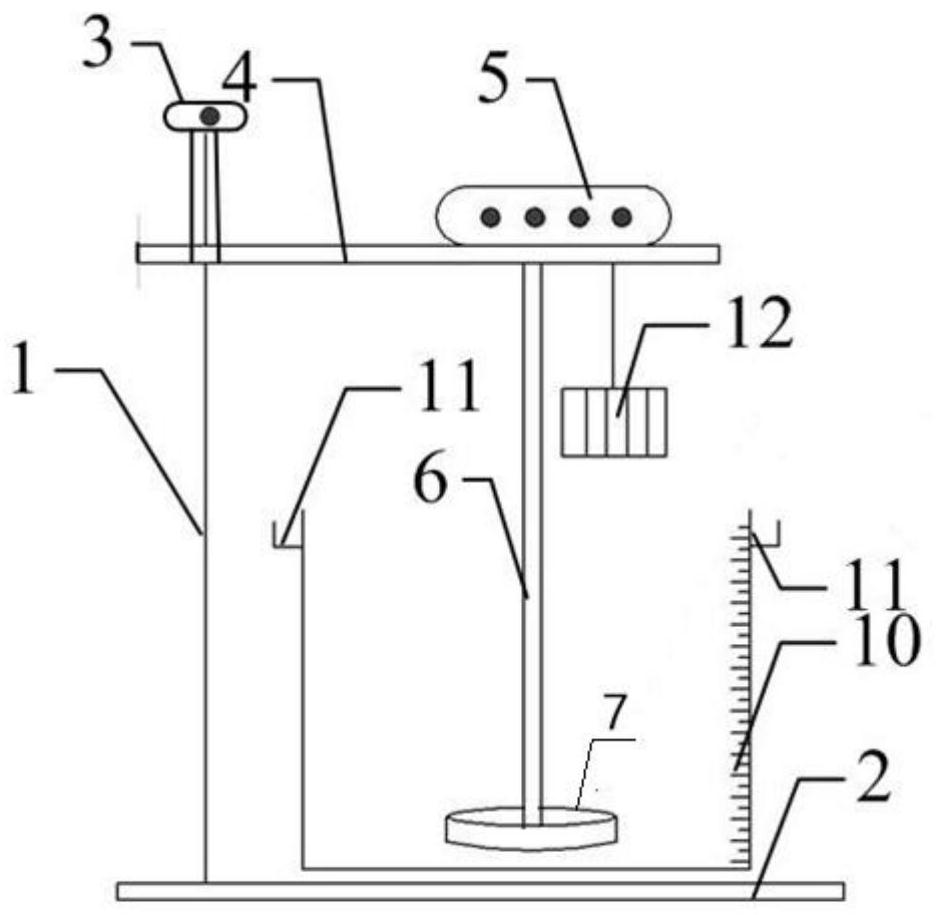

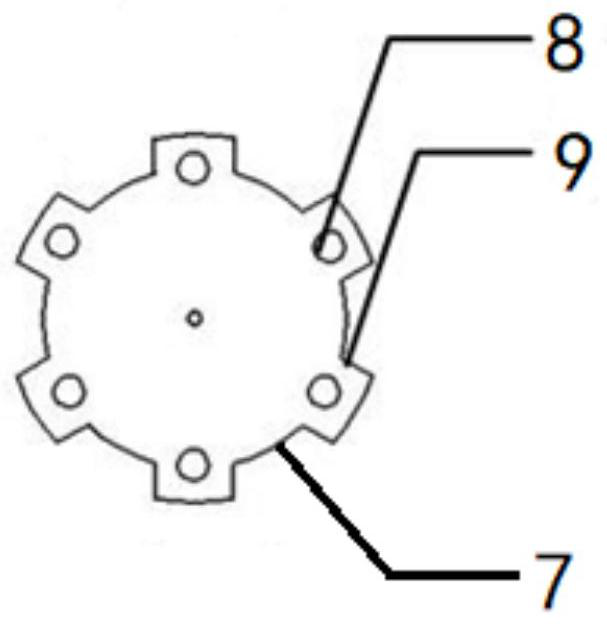

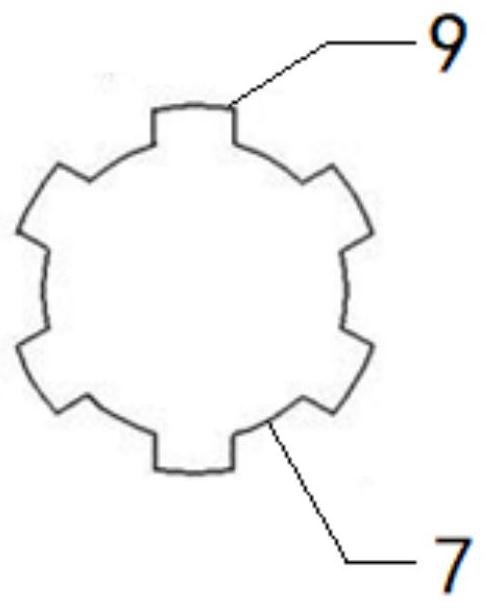

[0047] Embodiments of the present invention provide a detection system for inhibition and defoaming, see figure 1 , Including support assemblies, bubble components, quantitative test components, and control assemblies 5. See figure 1The quantitative test assembly includes a quantitative test container 10, a clamp 12, and a test plate. Quantitative test container 10 has a volumetric scale. The clamp 12 is located above the quantitative test container 10 for securing the test plate. The bubble assembly includes a venting shaft 6 and a turntable 7; the venting shaft 6 is a hollow structure, and the lower end of the venting shaft 6 is fixed to the turntable 7. The inner portion of the venting shaft is connected to the turntable, located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com