Intelligent checking device for welding and thermal cutting safety technology

A safety technology, thermal cutting technology, which is applied in the field of welding and thermal cutting safety technology intelligent assessment device, can solve the problems that the effect cannot meet the expected requirements, safety hazards, high training costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

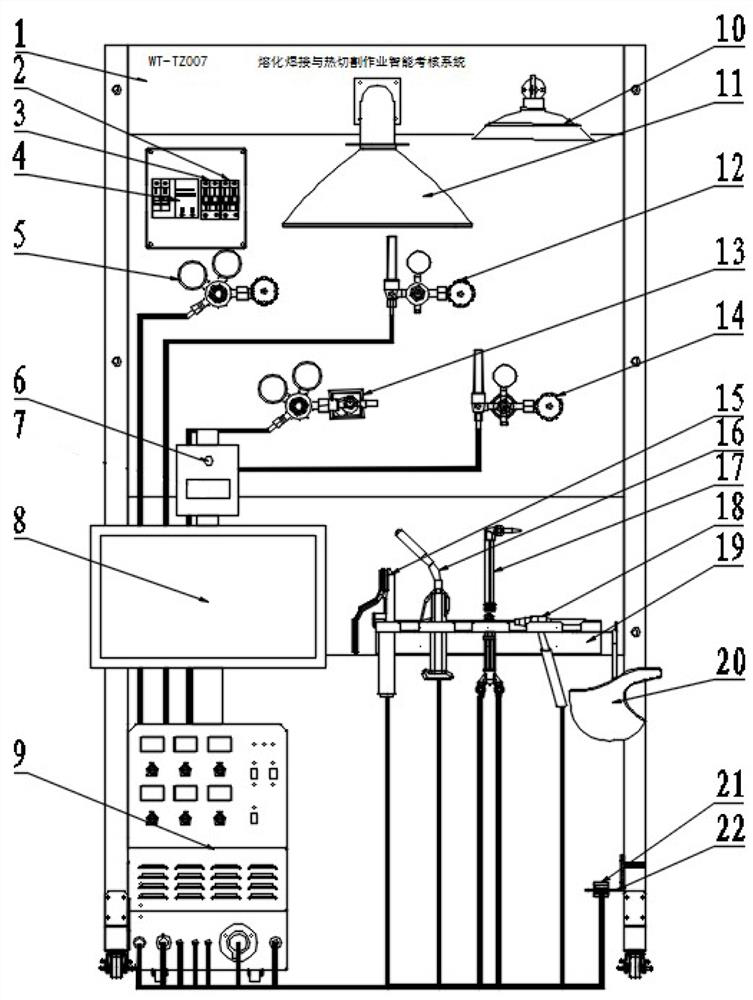

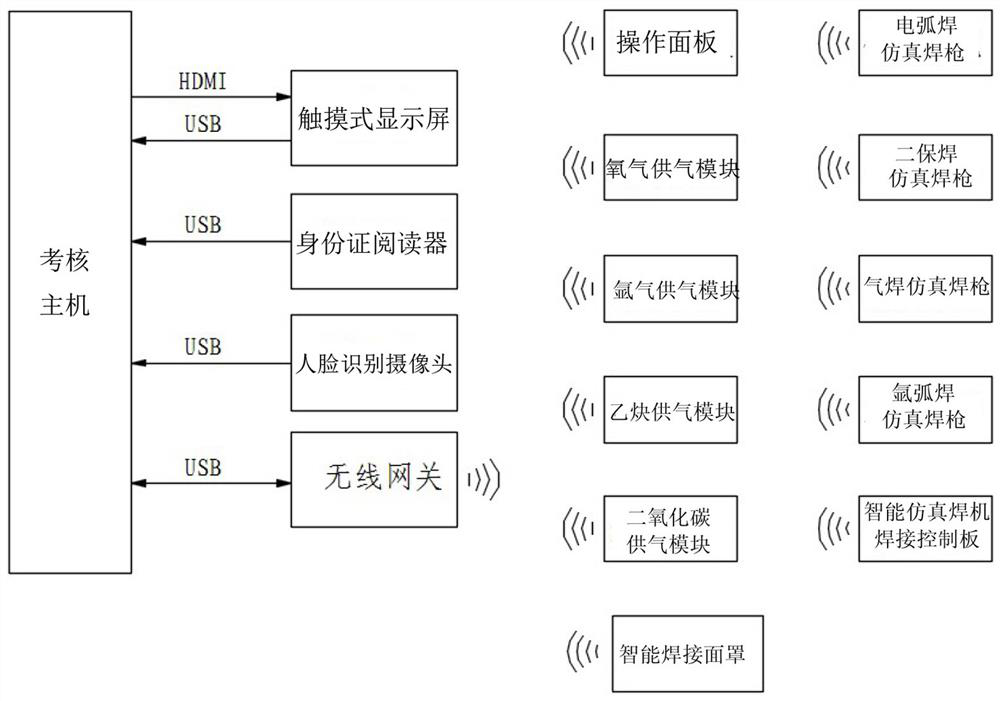

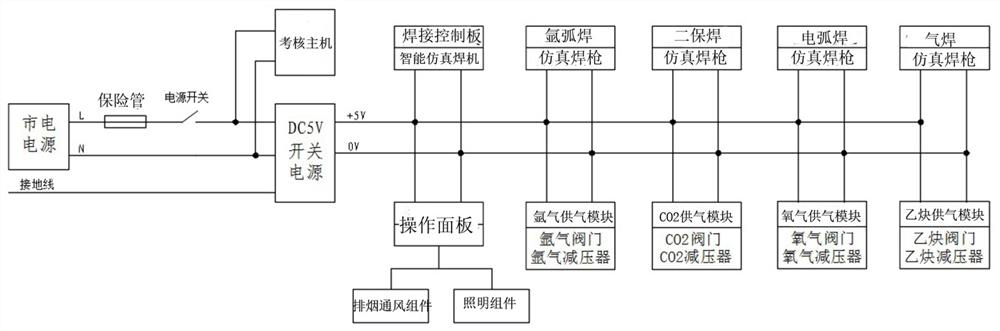

[0034] This embodiment provides an intelligent assessment device for welding and thermal cutting safety technology, such as Figure 1-5 As shown, an intelligent assessment device for welding and thermal cutting safety technology includes an operation panel 1, the upper part of the operation panel 1 is provided with an air supply unit and a smoke exhaust ventilation unit; the middle part of the operation panel 1 is provided with a witness collection unit 6 and A touch display screen 8; the lower part of the operation panel 1 is respectively provided with an intelligent simulation welding machine 9, a tool hanger and a weldment grounding assembly, and the tool hanger is successively mounted with a simulation welding torch and an intelligent welding mask 20; The weldment grounding component is used to detect whether the weldment is normally grounded during the welding operation; the weldment grounding component includes a grounding clip 21 and a grounding point 22;

[0035] The g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap