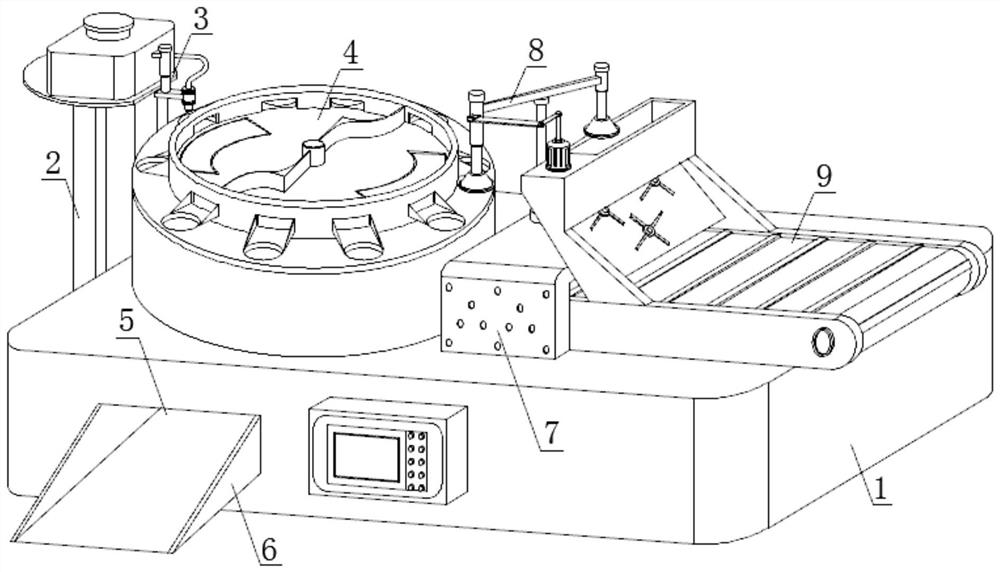

LED surface mounting device with bulk material classification structure and implementation method thereof

A technology of LED patch and classification structure, applied in the direction of electrical components, electrical components, etc., can solve the problems of untimely blanking of LED patch lamps, influence of patch efficiency, and inability to check whether the size of LED chips is qualified or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] For a better demonstration, this embodiment provides an implementation method of an LED patch device with a bulk material classification structure, including the following steps:

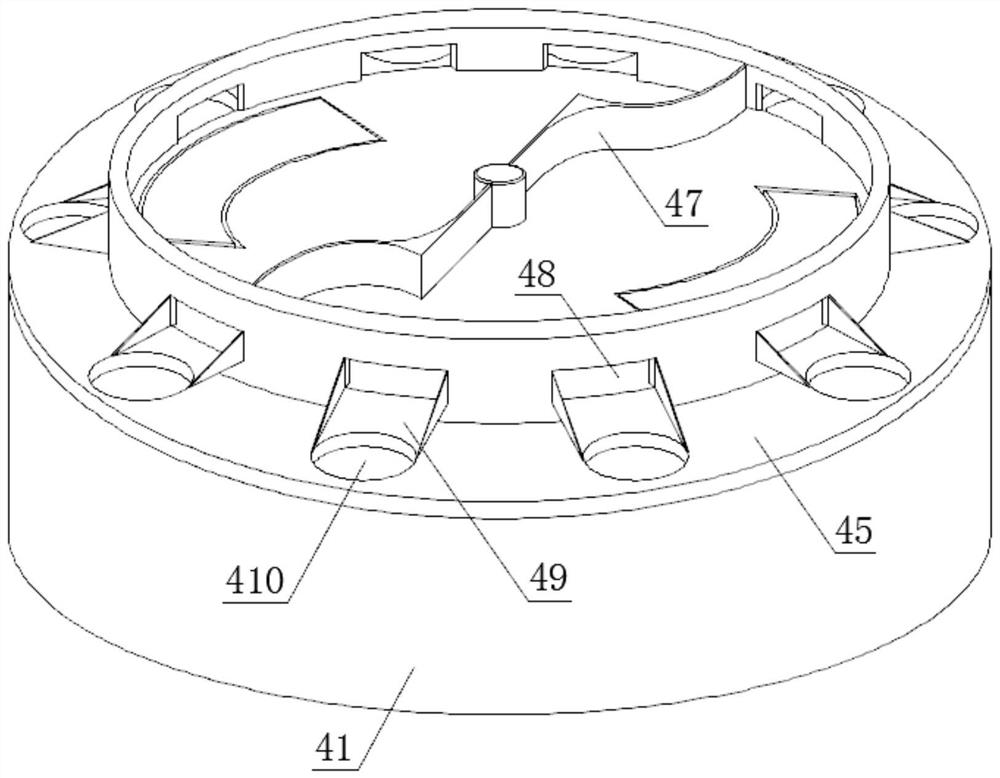

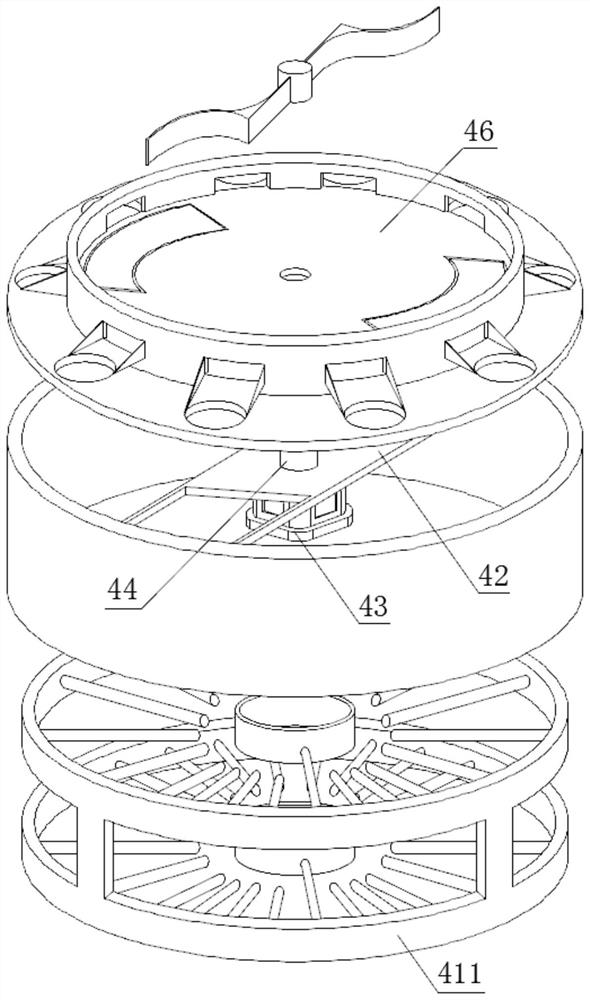

[0057] Step 1: Place a certain number of LED chips with patches in the distribution tray 46, start the drive motor 43 to cooperate with the rotating shaft 44 to drive the distribution tray 46 to rotate, and use the centrifugal force to push the chips to its edge when the distribution tray 46 rotates At the same time, the gear 442 on the outer wall of the protruding rod 441 on the top of the rotating shaft 44 meshes with the gear ring 472 inside the fixed sleeve 471, and cooperates with the centrifugal force to drive the shifting plates 473 on both sides of the fixed sleeve 471 to move the chips, and move them from the distribution tray. The sorting port 48 on the side wall of 46 is discharged and slides down to the patch groove 410 on the top of the rotating disk 45 by means of the inclined sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com