Degradable extrusion webs made from polymer blend compositions

A composition, polymer technology, applied to the main or key elements of the subject matter, the composition may contain one or more polymers, the field of extruded plastic nets, able to solve the problems of environmental hazards, consumption, multiple landfill areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

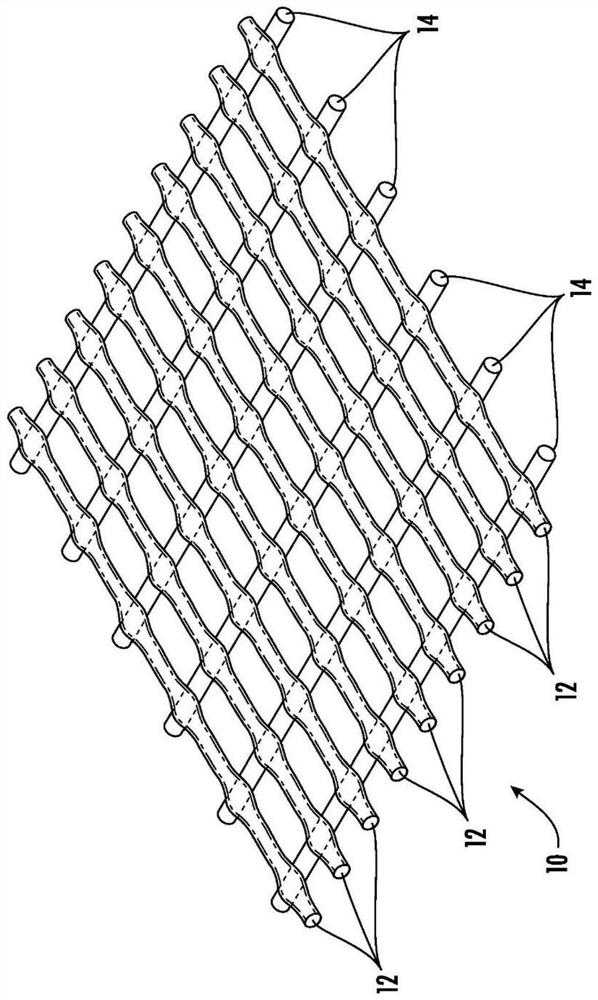

Image

Examples

Embodiment 1

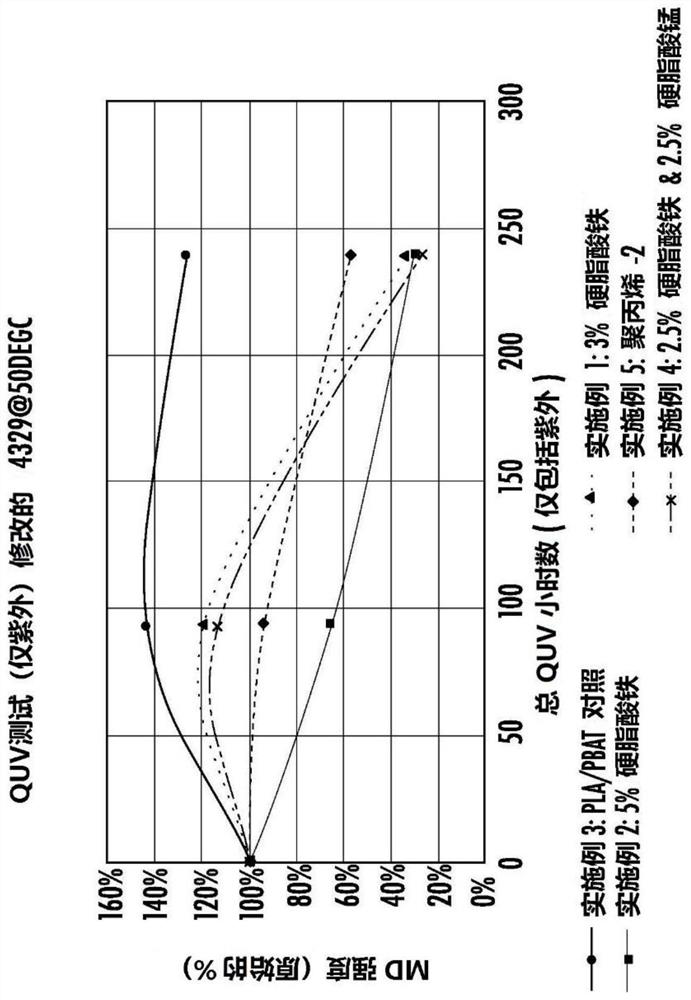

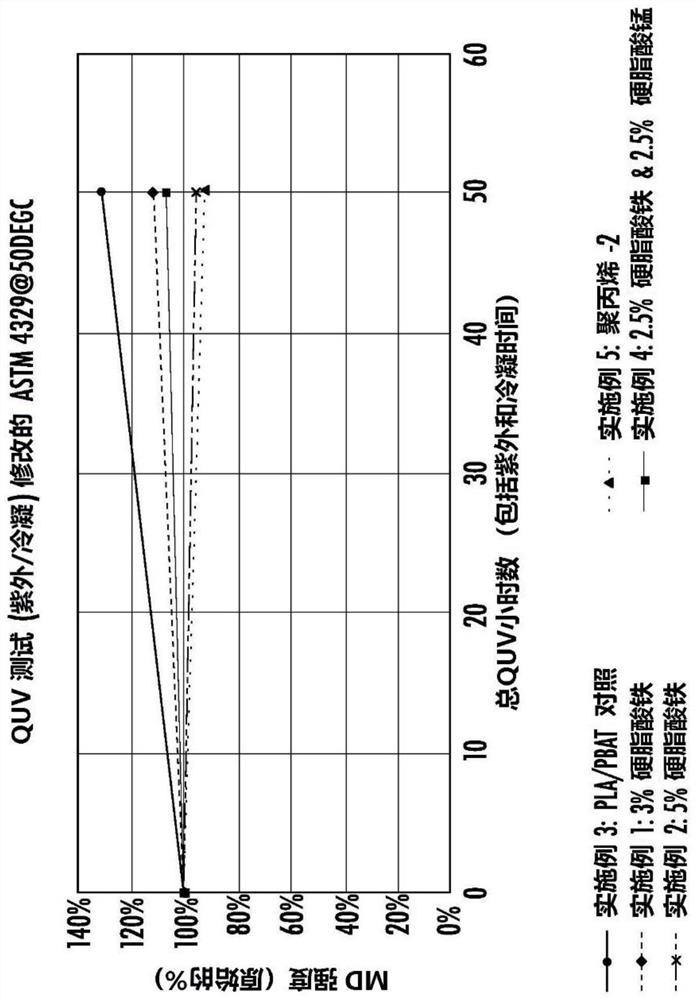

[0075] Degradable extruded films according to the present disclosure were made using a mixture comprising 57% by weight of biopolymer 2003D (under the trade name Ingeo). TM Sold, available from NatureWorks) as a PLA composition, 38% by weight F Blend C1200 (under the trade name sold, available from BASF SE) as a PBAT composition, 2% by weight of TECHMER PLAM111474 compatibilizer and 3% by weight of a degradation additive comprising 5% iron stearate and 95% PLA carrier resin. Films are produced by well known extrusion methods wherein the composition is extruded through the desired die at a temperature of about 355 to about 380 degrees Fahrenheit. After extrusion, the film enters nip rolls and finally into a rollstack.

Embodiment 2

[0077] A degradable extruded film according to the present disclosure was made using a mixture comprising 55% by weight Biopolymer 2003D as PLA composition, 38% by weight F Blend C1200 as PBAT composition, 2% by weight TECHMER PLAM111474 compatibilizer and 5% by weight degradation additive comprising 5% iron stearate and 95% PLA carrier resin. Films of the composition of Example 2 were extruded using the same method as in Example 1 .

Embodiment 3

[0079] A degradable extruded film according to the present disclosure was made using a mixture comprising 60% by weight Biopolymer 2003D as PLA composition, 38% by weight F Blend C1200 as PBAT composition, 2% by weight TECHMER PLAM111474 compatibilizer and no degradant additives. Films of the composition of Example 3 were extruded using the same method as in Example 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap