Simple and rapid inspection device for load test of balance beam for ship and use method of simple and rapid inspection device

An inspection device and load test technology, which is applied in the field of balance beam inspection, can solve the problems of long time, large test limitations, and high cost, and achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

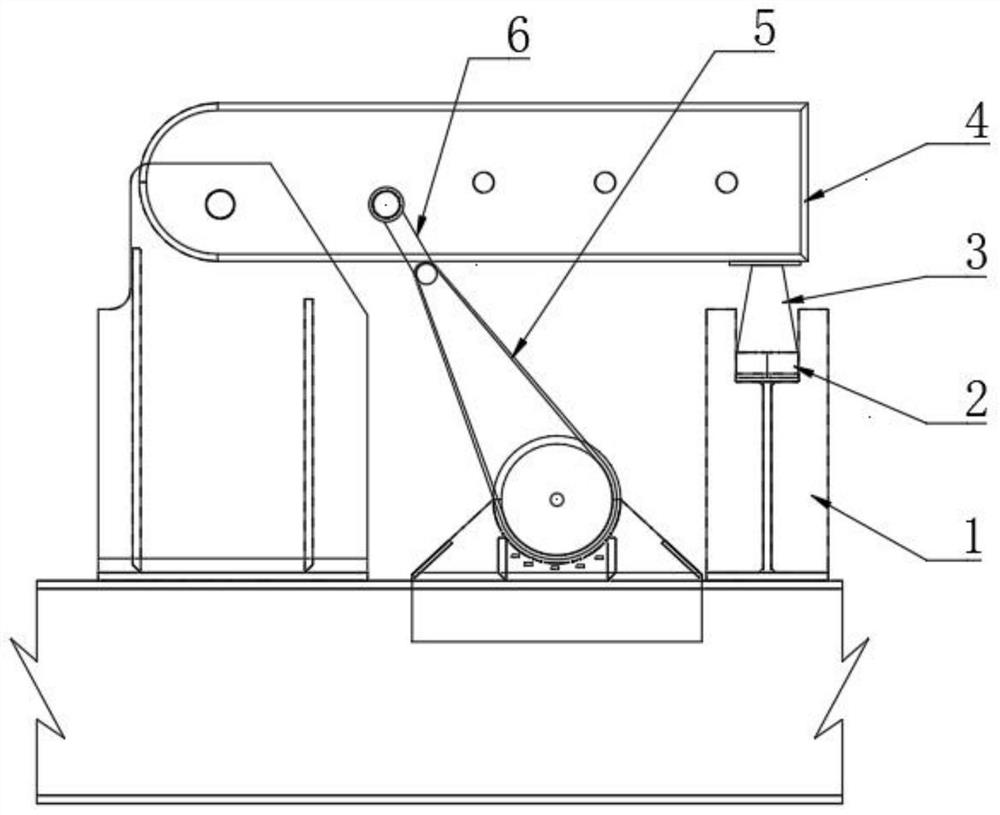

[0035] Please refer to figure 1 As shown, the present invention provides a simple and quick inspection device for a load test of a balance beam for ships, including a tooling piece 4, the tooling piece 4 is composed of a support frame and a tooling bar, one end of the tooling bar and the support frame are hingedly fixed, and the tooling bar is hinged and fixed. A base 1 is arranged below the other end, a jack 3 is arranged at the top of the base 1, a pressure gauge 2 is arranged at the bottom of the jack 3, the top of the jack 3 is in contact with the bottom of the end of the tooling bar, and a shackle 6 is arranged on the tooling bar. 6 is provided with a wire rope 5 for connecting the balance beam.

[0036] A method of using a simple and quick inspection device for ship balance beam load test:

[0037] S1. Check the UT inspection report of the balance beam weld to confirm whether the tensile test can be performed;

[0038] S2. Move the balance beam to the designated test s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com