A kind of superhydrophobic superoleophobic coating and preparation method thereof

A super-hydrophobic, super-oleophobic, and coating technology, which is applied in coatings and other directions, can solve the problems of complex preparation methods of super-amphiphobic surfaces, high cost, and narrow application range of super-amphiphobic surfaces, achieving low cost, non-pollution, and synthetic high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

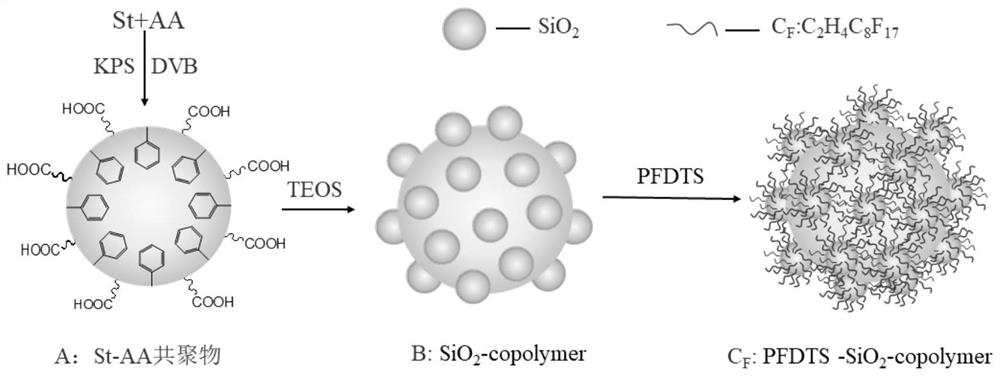

[0032] The preparation method of the superhydrophobic superoleophobic coating provided by the invention is as follows:

[0033] 1. Preparation of St-AA copolymer emulsion:

[0034] Add deionized water, styrene, acrylic monomer, initiator and cross-linking monomer divinylbenzene in turn to the three-necked flask, stir well at room temperature, then heat to 40~90℃, keep warm for 1~10h The obtained white emulsion was directly used in the next reaction.

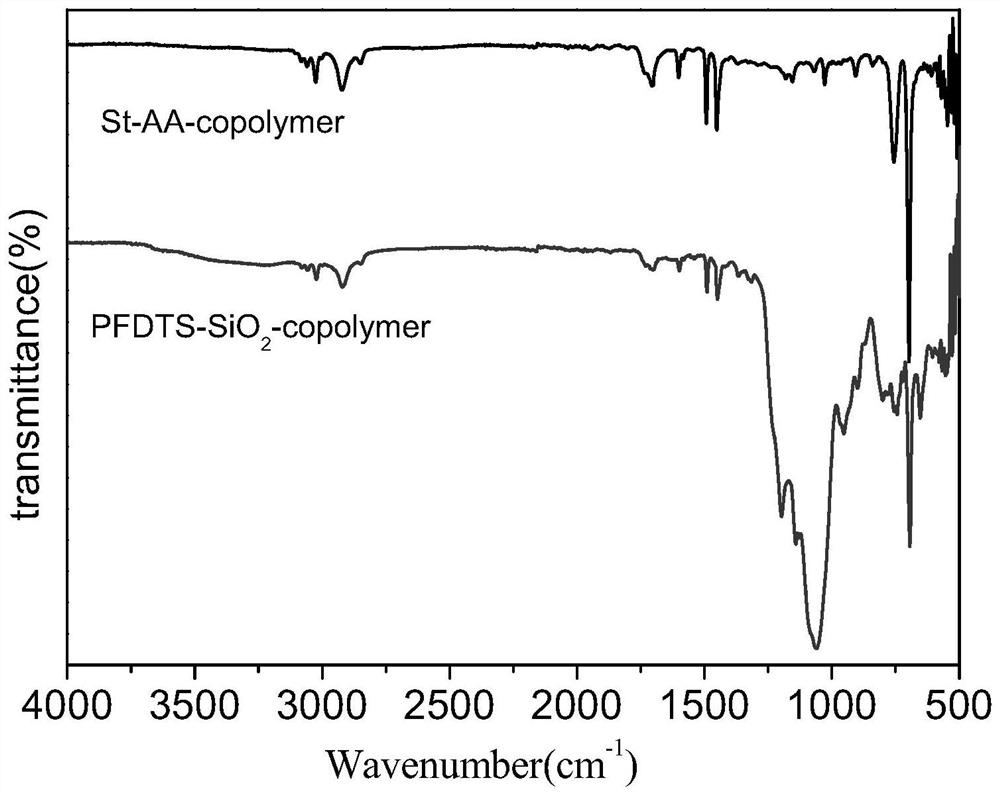

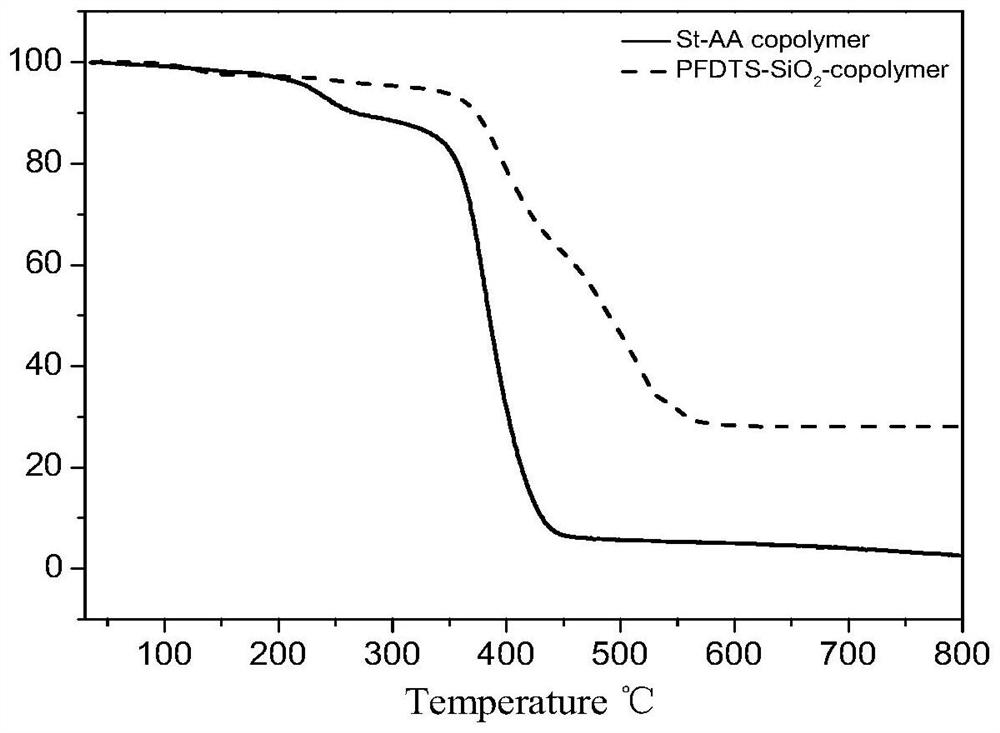

[0035] 2. PFDTS-SiO 2 -copolymer emulsion synthesis:

[0036] Add ethanol, orthosilicate, and the above-mentioned copolymer emulsion into the three-necked bottle in turn, and stir to obtain a uniform emulsion. Then add ammonia water, stir and heat to 30-80 DEG C, keep the temperature for 0.5-8 hours, add fluorosilicone, continue keeping the temperature for 0.5-8 hours, stop the experiment, and obtain a raspberry-like nanoparticle emulsion.

[0037] The specific process is, when preparing the St-AA copolymer emulsion, acrylic ...

Embodiment 1

[0040] First, 2.5g of styrene, 1.0g of acrylic acid, 0.015g of potassium persulfate, 150μL of divinylbenzene, and 50mL of deionized water were added to a three-necked flask, stirred at room temperature for 30min, and then heated to 78°C (200rpm) , the obtained white emulsion after 6h of incubation. Then, 15 mL of ethanol, 1 mL of ethyl orthosilicate, and 6 mL of white emulsion were sequentially added to the three-necked flask, and stirred for 30 mins to obtain a uniform emulsion. Add 0.5 mL of ammonia water with a volume percentage of 25%, stir and heat to 60° C., hold for 90 minutes, add 50 μL of PFDTS, continue to hold for 90 minutes, and stop the experiment. The obtained PFDTS-SiO 2 -copolymer emulsion for the preparation of coating films.

Embodiment 2

[0042] First, 1.5g of styrene, 2.0g of methacrylic acid, 0.020g of ammonium persulfate, 150μL of divinylbenzene, and 50mL of deionized water were added to the three-necked flask, stirred at room temperature for 50min, and then heated to 85°C ( 300 rpm), the obtained white emulsion was obtained after 9 h of incubation. Then, 20 mL of methanol, 1.5 mL of methyl orthosilicate, and 6 mL of white emulsion were sequentially added to the three-necked flask, and stirred for 50 mins to obtain a uniform emulsion. Add 0.5 mL of ammonia water with a volume percentage of 25%, stir and heat to 70° C., hold for 60 minutes, add 100 μL of PFOTS, continue to hold for 8 hours, and stop the experiment. The obtained PFOTS-SiO 2 -copolymer emulsion for the preparation of coating films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com