Automatic matching type cold spraying device

A technology of automatic proportioning and spraying gun, applied in the direction of spraying device, etc., can solve the problems of low spraying efficiency of spraying device, and achieve the effect of high spraying efficiency, reducing control difficulty and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

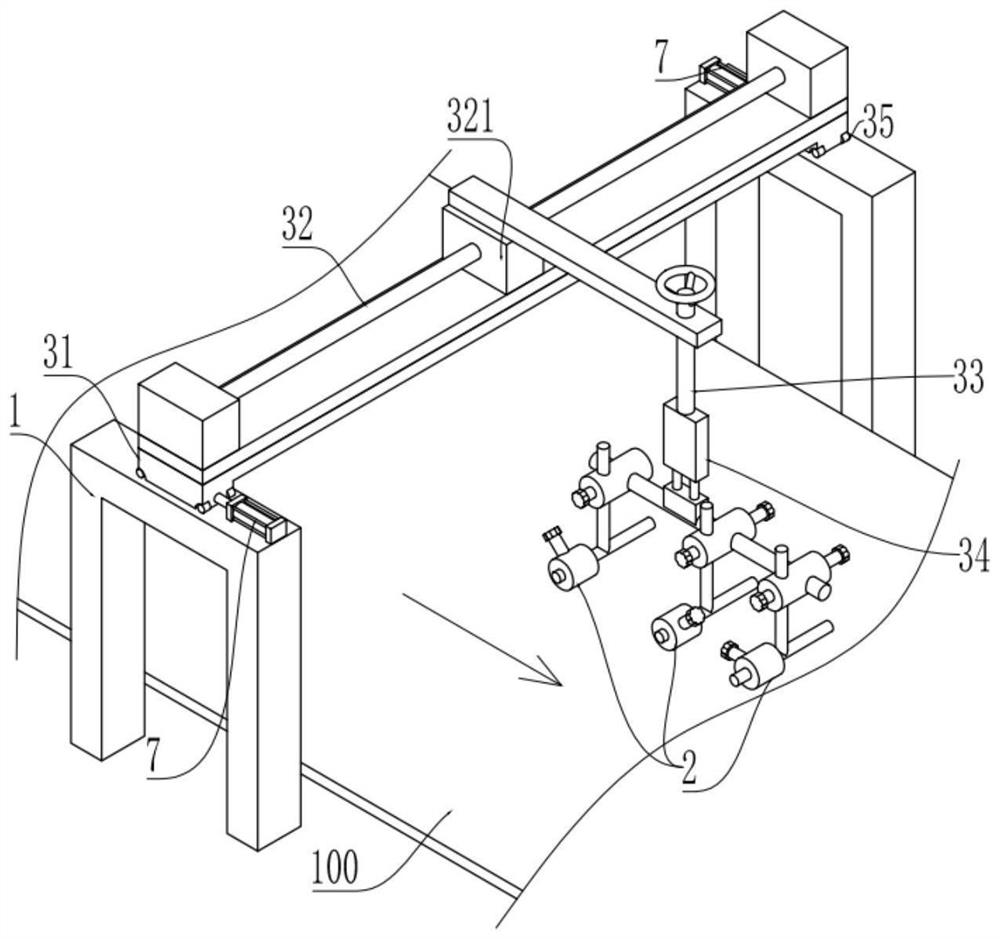

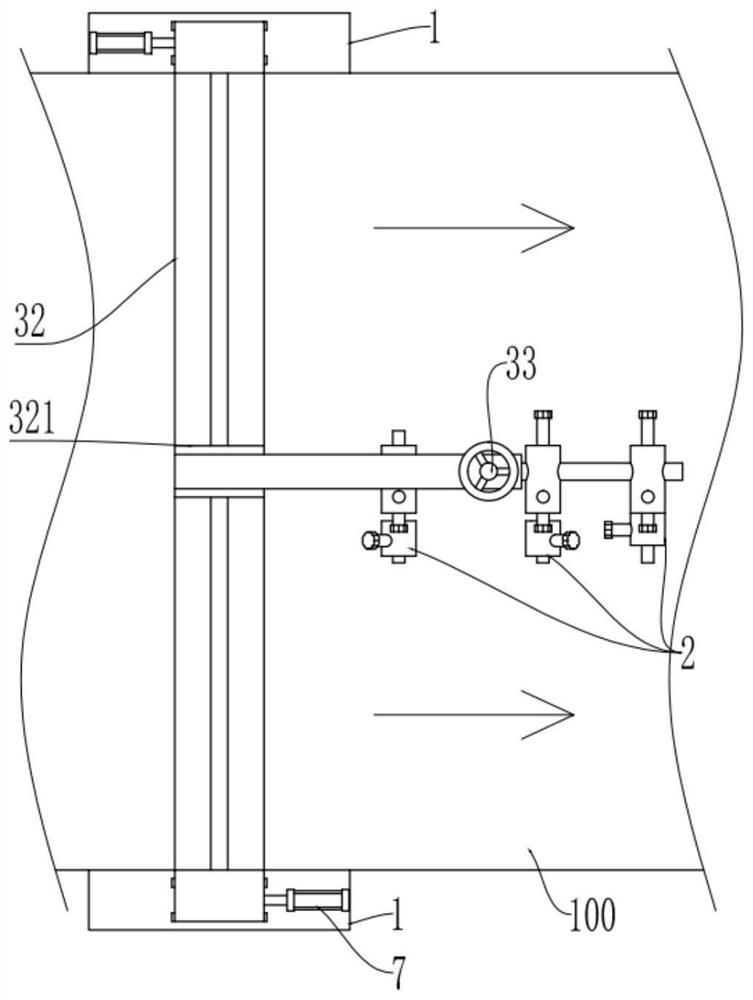

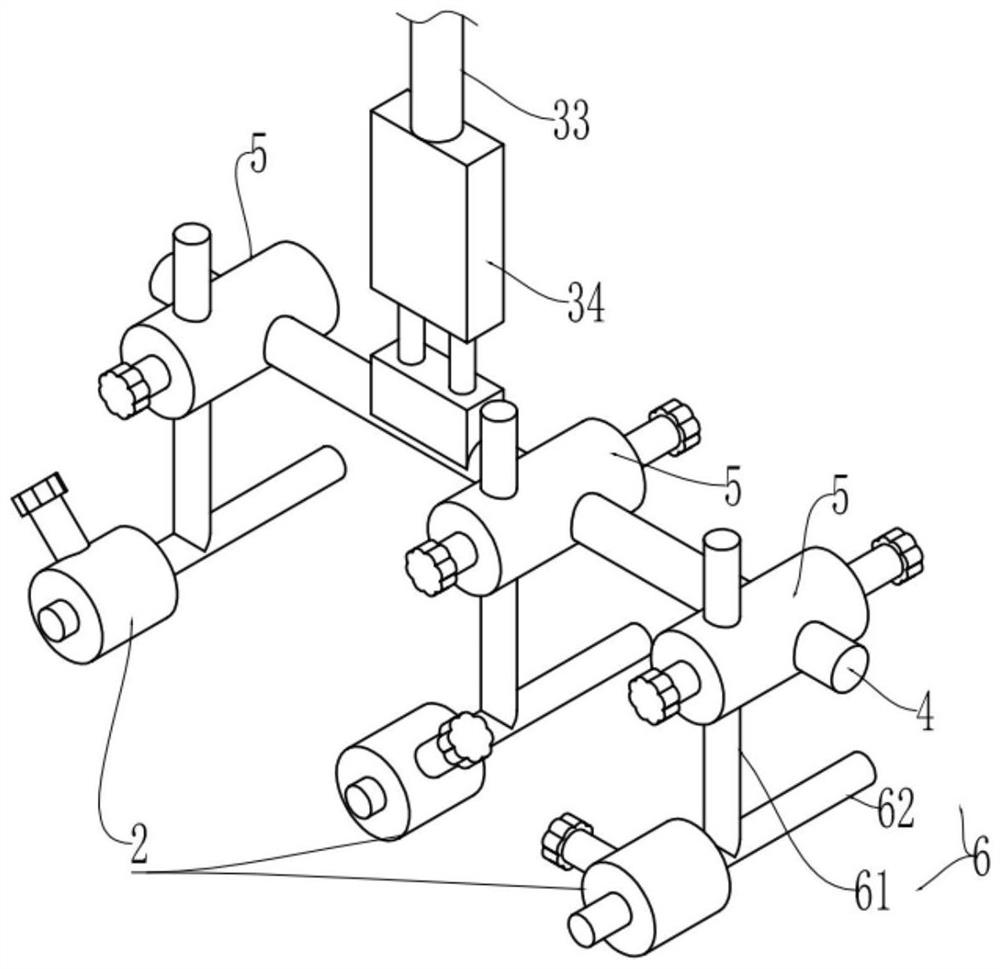

[0038] Embodiment one is basically as attached Figure 1 to Figure 3 Shown, a kind of automatic proportioning type cold spray device comprises automatic proportioning system and spraying system, and automatic proportioning system can be used for preparing spraying solution, and spraying system comprises frame 1, mover and spray gun 2 (spray gun 2 among the figure is only a schematic diagram), the frame 1 is fixedly connected on the ground, the conveying line 100 of the glass bottle is located below the frame 1, and the mover is installed on the frame 1, and the mover includes a support 31, a linear module 32, a lifting rod 33 and The lifter 34 and the linear module 32 are fixedly installed on the support 31, the bottom of the support 31 is provided with a universal roller 35, the universal roller 35 can move on the frame 1, the output end of the linear module 32 is a slide block 321, the linear The module 32 drives the slider 321 to move horizontally, and the linear module 32 ...

Embodiment 2

[0048] Embodiment two is basically as attached Figure 4 As shown, the difference between embodiment two and embodiment one is that the automatic proportioning system includes at least two mixing tanks (the number of mixing tanks in this embodiment is 2, such as mixing tank A and mixing tank B) , the output end of each mixing tank is connected with the spray gun 2, and the pipeline connecting each mixing tank with the spray gun 2 is equipped with a valve 8. The more specific structure of the automatic proportioning system is as follows: each mixing tank Including an inlet and an output. The output of each mixing tank is connected to a pipeline. A valve 8 is installed on the output pipeline. In this embodiment, the valve 8 is a butterfly valve. The other end of the output pipeline of each mixing tank All are communicated with the pipeline leading to the spray gun 2, so as to supply the spray solution for the spray gun 2; at the inlet end of the mixing tank, according to the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com