Buffer type overflow valve structure

A relief valve and valve body technology, applied in the field of hydraulic relief valves, can solve problems such as poor buffering effect, achieve sufficient buffering time, obvious effect, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

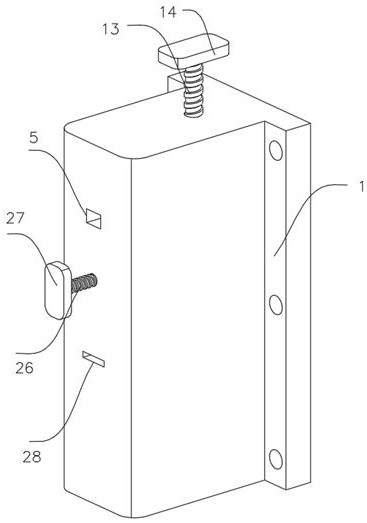

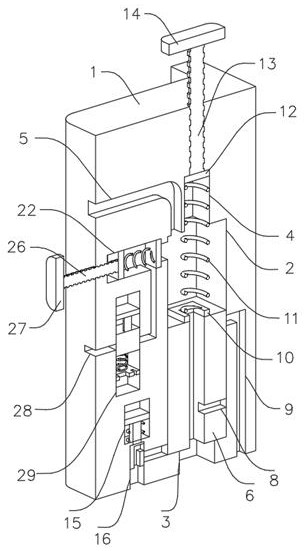

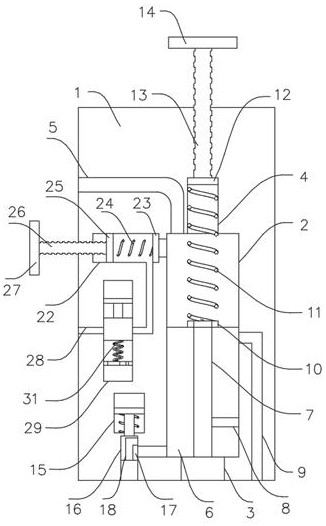

[0023] refer to Figure 1-6 , buffer relief valve structure, including a valve body 1, a valve chamber 2 is opened inside the valve body 1, an oil inlet 3 and an oil outlet 5 are opened through the side wall of the valve chamber 2, and an oil inlet 3 and an oil outlet 5 are opened on the inner wall of the valve chamber 2. The adjustment groove 4, the inner wall of the valve cavity 2 is sealed and slidingly connected with the valve core 6, the oil inlet 3 and the oil outlet 5 are located at both ends of the valve core 6, and the oil outlet 5 can be blocked and closed when the valve core 6 moves to the limit position The side wall of the valve core 6 is provided with an oil return hole 7, the side wall of the oil passage 7 is provided with an oil return hole 8, and the inner wall of the valve cavity 2 is provided with an oil return port 9 matching the oil return hole 8, The end of the spool 6 is fixed with a connecting block 10, and the connecting block 10 is connected with a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com