Precise bearing for mechanical equipment

A technology of precision bearings and mechanical equipment, applied in the direction of mechanical equipment, bearing components, shafts and bearings, etc., can solve the problems of messy placement of sealing covers, high labor intensity, skewed installation of sealing covers, etc., to improve practicability and flexibility, Improve usability and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

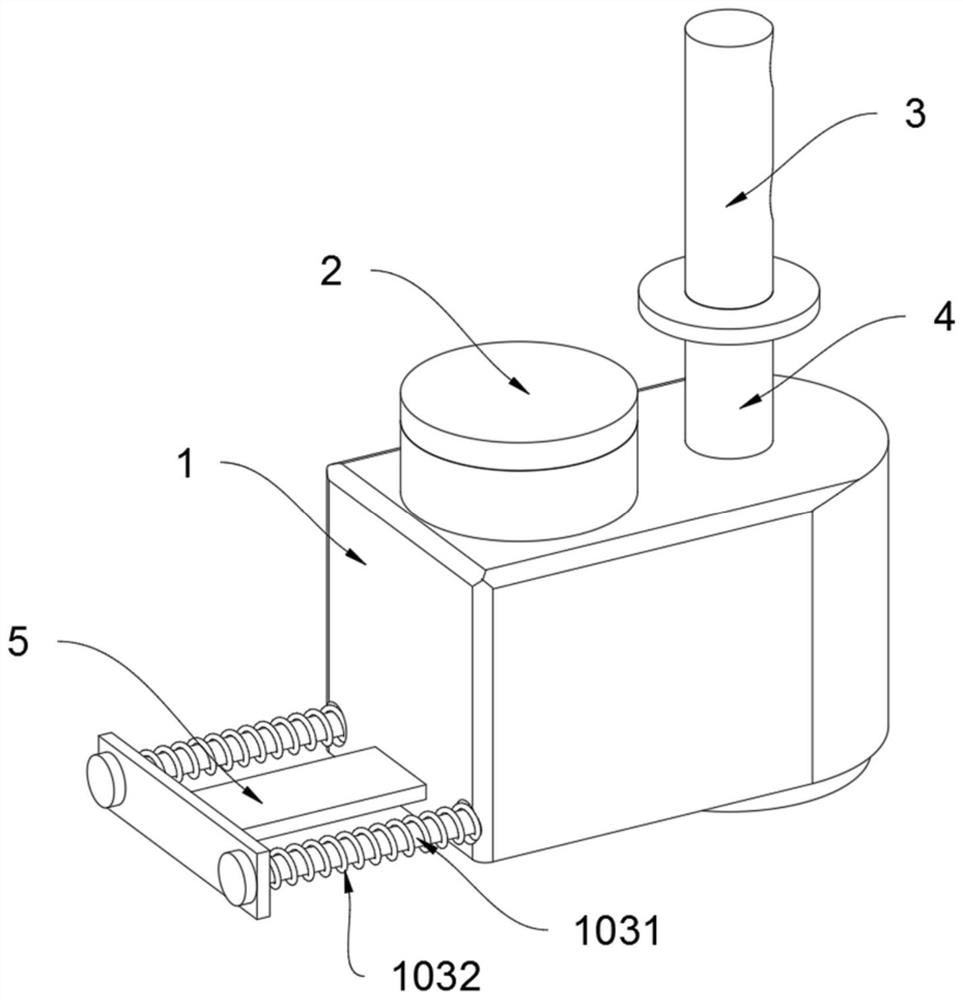

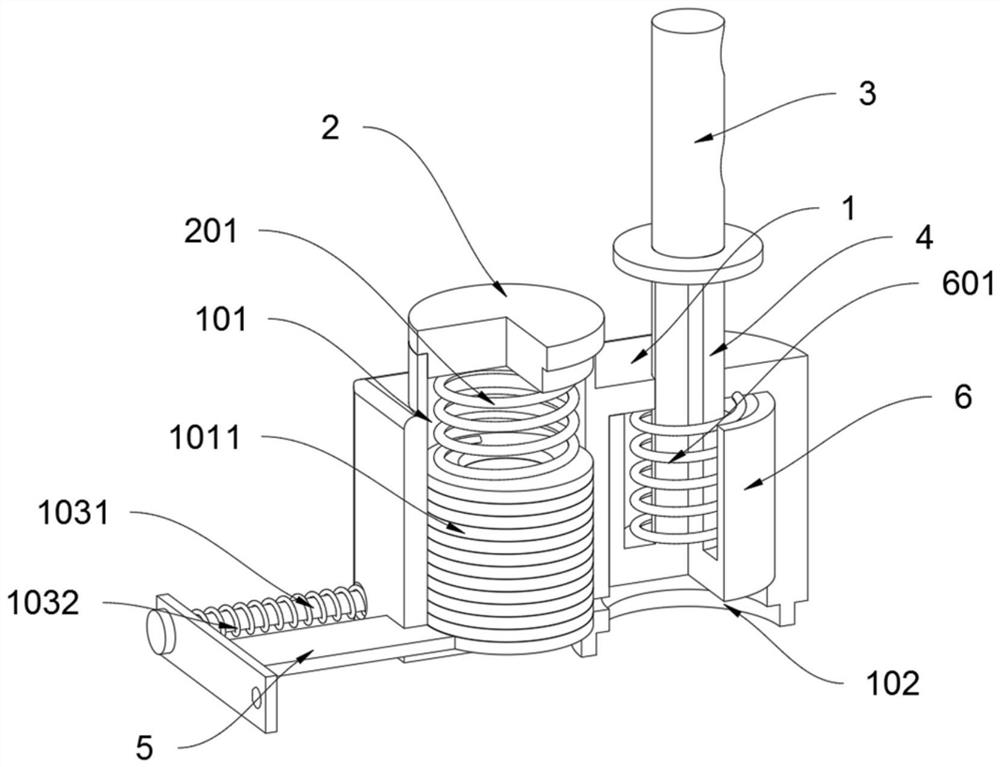

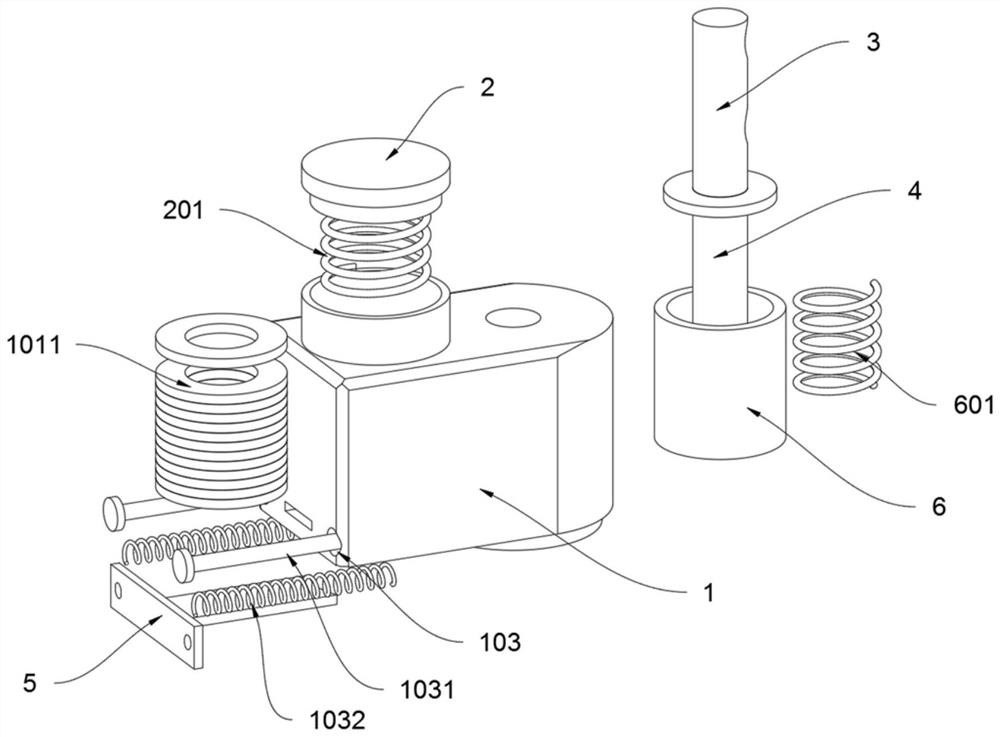

[0030] as attached figure 1 to attach Figure 6 Shown:

[0031] The invention provides a precision bearing for mechanical equipment, comprising a housing 1, a handle 3 and a push piece 5; the top of the housing 1 is screwed with a top compartment cover 2; the inner left side of the housing 1 is provided with a sealing cover compartment 101, and a bearing sealing cover 1011 is plugged into the inside of the sealing cover warehouse 101, and the bottom of the housing 1 is provided with a bearing positioning hole 102, as attached figure 1 , attached figure 2 And attached image 3 As shown, this design enables the bearing sealing cover 1011 to be collected and stored in a unified manner, which is convenient for subsequent installation and use, and improves the flexibility of the device; the grip bar 3 is fixedly connected to the top of the linkage bar 4; the bottom end of the linkage bar 4 is fixedly connected to the installation The inside of the pressure cylinder 6; the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com