Center console detection frame

A technology for testing racks and center consoles, which can be used in measuring devices, vehicle testing, mechanical parts testing, etc., and can solve problems such as inconvenient support for the center console

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

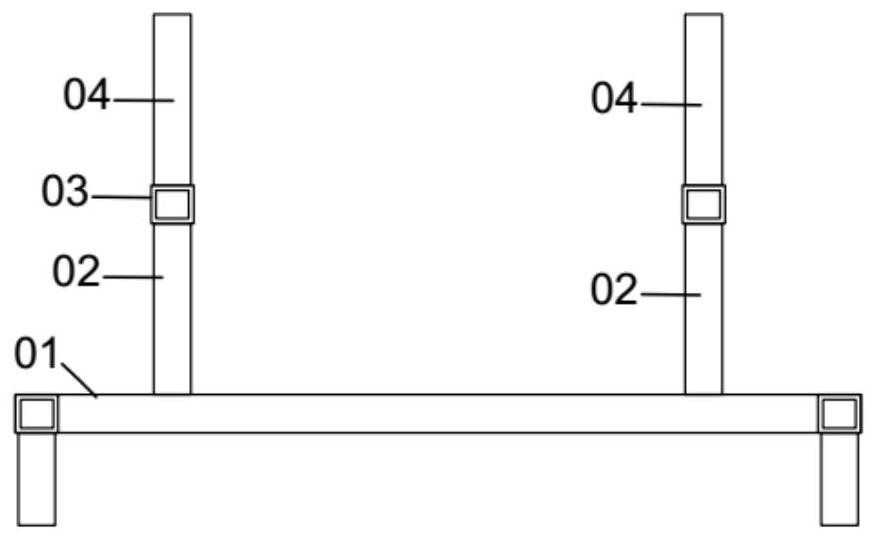

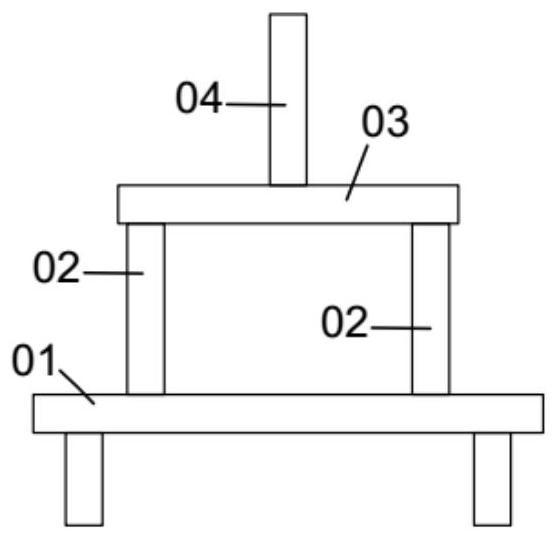

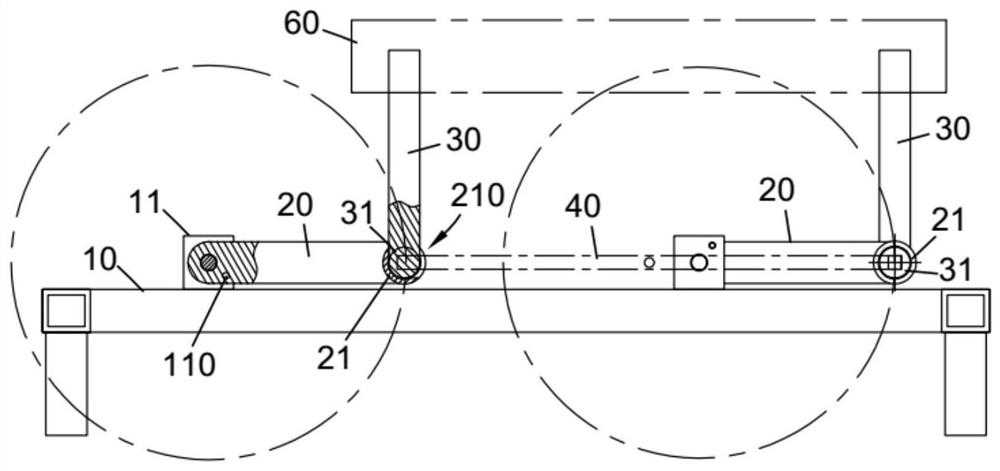

[0027] combine image 3 , Figure 4 , a center console detection frame, including a base 10, a pair of brackets arranged on the base and located on the left and right sides of the base, any bracket includes a pair of uprights 20 hinged on the base, and a pair of horizontal columns fixed on the pair of uprights Rod 21, the crossbar is hollow, and the crossbar is equipped with a rotating shaft 31, which is fixedly connected with the pillar 30; the end of the rotating shaft is provided with a polygonal groove 310, combined with Figure 8 to Figure 10 The two ends of a connecting rod 40 are provided with polygonal protrusions 41, and the polygonal protrusions at both ends of the connecting rod cooperate with the polygonal grooves of the two rotating shafts of a pair of brackets in a one-to-one manner.

[0028] A pair of supports includes a first support and a second support. initial, combined image 3 , Figure 4 , the detector puts down a pair of uprights 20 of the first brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com