Single-side rotary digging type small sweet potato harvester

A harvester, sweet potato technology, applied in excavating harvesters, excavators, harvesters and other directions, can solve the problems of missed harvesting or crushing sweet potatoes, poor separation effect of soil and sweet potatoes, etc. The effect of improving the separation and improving the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

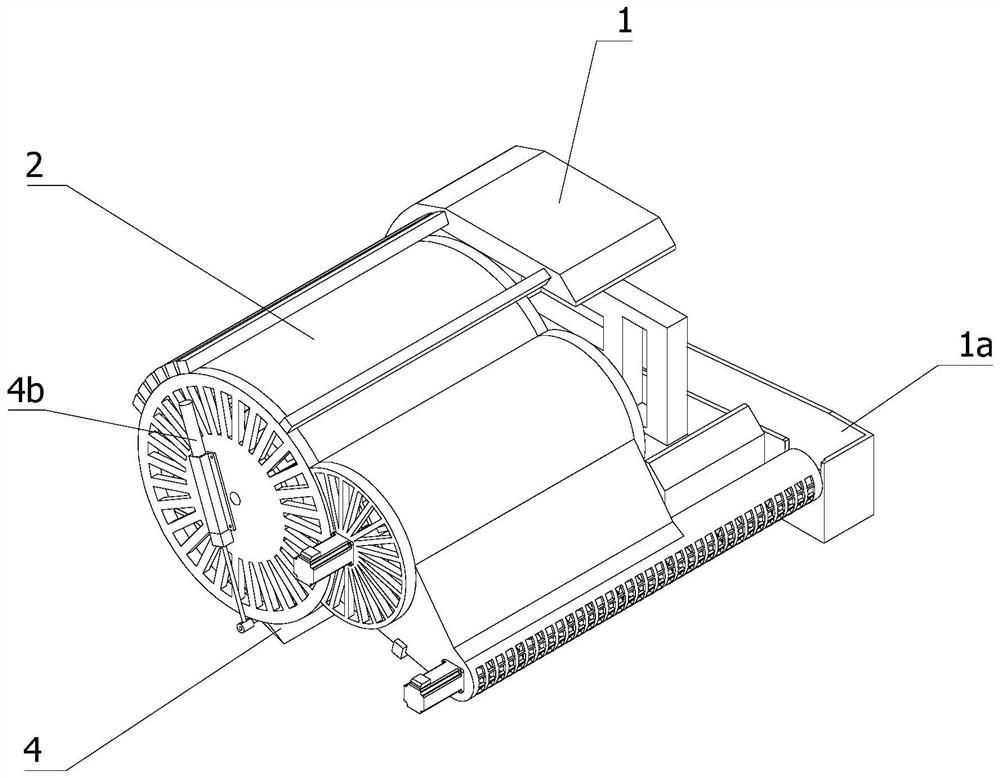

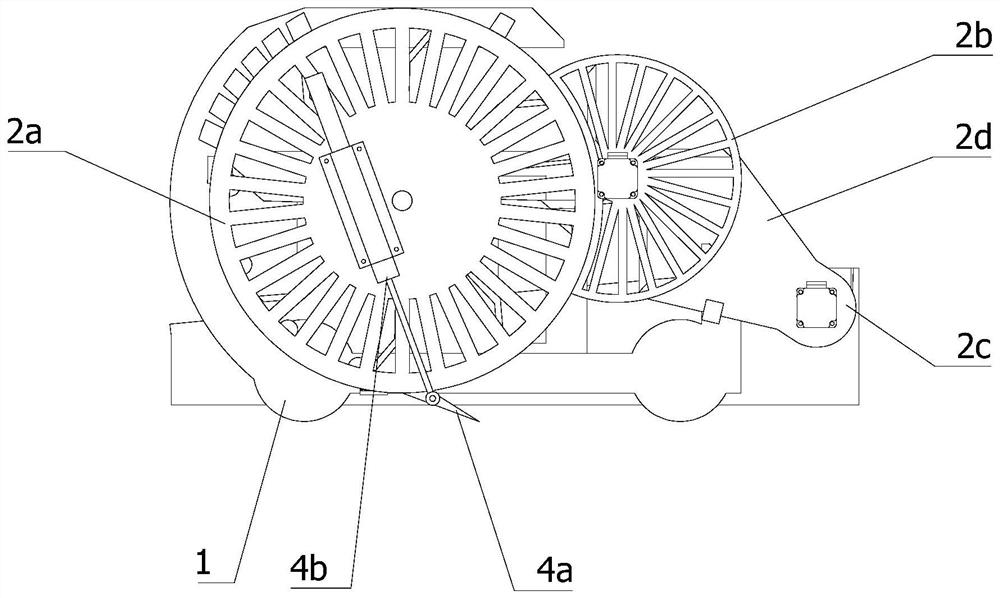

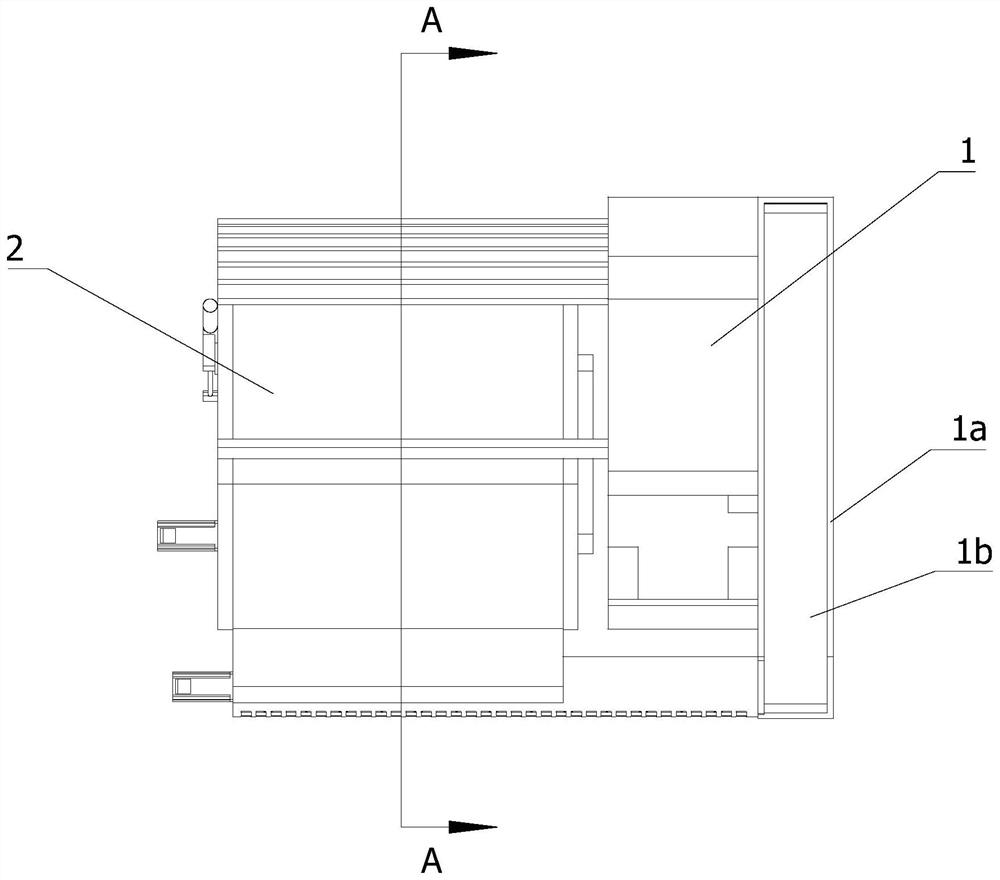

[0046] Such as Figure 1-Figure 12 As shown, this application provides:

[0047] A single-side rotary digging small-sized sweet potato harvester, comprising a harvesting channel 2 arranged on a car body 1 and a harvesting device 3 arranged on the harvesting channel 2, and the harvesting channel 2 is located on one side of the car body 1 , and the other side of the car body 1 is also provided with a strip material frame 1a in a horizontal state. Rotary digging mechanism 3a and the transfer mechanism 3b in order to dial away the sweet potatoes dug on the rotary digging mechanism 3a and the screw conveyor 3c in order to transfer the sweet potatoes that the transfer mechanism 3b dials to the strip materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com